High-yield gamma-polyglutamic acid (gamma-PGA) bacterial strain and method for producing gamma-PGA through gamma-PGA bacterial strain

A strain and high-yield technology, applied in the direction of sterilization method, microorganism-based method, support/immobilization method of microorganisms, etc., can solve the problems of complicated process, non-recyclable bacteria, high energy consumption, etc., and achieve simple process, Realize the effect of reusing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

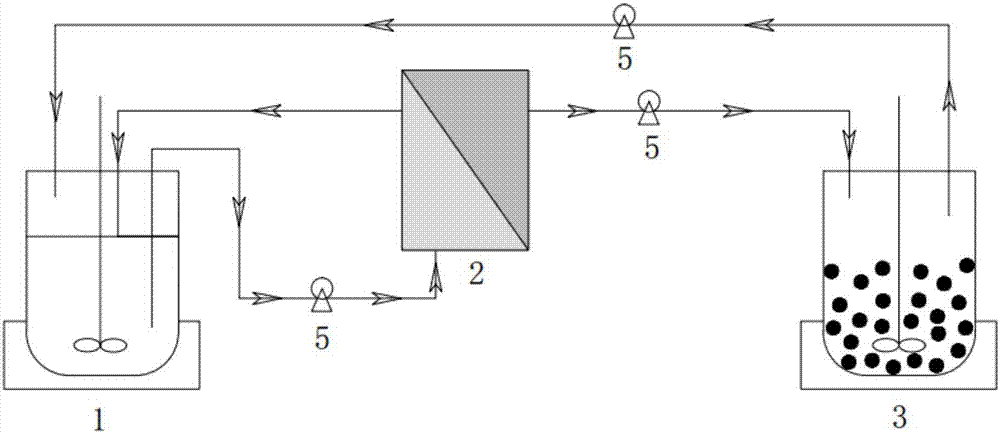

Method used

Image

Examples

Embodiment 1

[0042] Production of γ-polyglutamic acid with corn stalks as the main raw material:

[0043] 1) Seed culture: Inoculate the cryopreserved Bacillus amyloliquefaciens JX-12 on the slant of the sterile activation medium, the formula of the activation medium is: peptone 10g, beef extract 5g, NaCl 5g, agar 19g, pH 7.0~ 7.4, add water to 1000mL, and sterilize at 121°C for 30min. Cultivate at 37°C for 24 hours to activate, inoculate the activated strains on sterile seed medium, the formulation of the seed medium is: 10g of peptone, 5g of beef extract, 5g of NaCl, pH 7.0-7.4, replenish water to 1000mL, Sterilize at 121°C for 30min. Shake the flask for 24 hours under the conditions of 30° C. and 200 rpm to obtain the seed liquid.

[0044] 2) Preparation of immobilized cells: centrifuge the seed liquid at 5000 rpm and 4°C for 20 min, discard the supernatant, rinse 3 times with sterile 0.9% saline, suspend the cells with sterile water, and dilute to Concentration is 10 6 cfu / mL.

[...

Embodiment 2

[0058] Production of γ-polyglutamic acid with corn stalks as the main raw material:

[0059] 1) Seed culture: Inoculate the cryopreserved Bacillus amyloliquefaciens JX-12 on the slant of the sterile activation medium, the formula of the activation medium is: peptone 10g, beef extract 5g, NaCl 5g, agar 19g, pH 7.0~ 7.4, add water to 1000mL, and sterilize at 121°C for 30min. Cultivate at 37°C for 24 hours to activate, inoculate the activated strains on sterile seed medium, the formulation of the seed medium is: 10g of peptone, 5g of beef extract, 5g of NaCl, pH 7.0-7.4, replenish water to 1000mL, Sterilize at 121°C for 30 minutes. Shake the flask for 24 hours under the conditions of 30° C. and 200 rpm to obtain the seed liquid.

[0060] 2) Preparation of immobilized cells: centrifuge the seed liquid at 5000 rpm and 4°C for 20 min, discard the supernatant, rinse 3 times with sterile 0.9% saline, suspend the cells with sterile water, and dilute to Concentration is 10 6 cfu / mL....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com