Hydrogen production catalyst system, hydrogen production system comprising same and applications of hydrogen production catalyst system

A catalytic system and system technology, applied in the fields of energy and environment, can solve the problems of difficulty in control, increase the cost of hydrogen production, and reduce the hydrogen production efficiency of the reaction system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

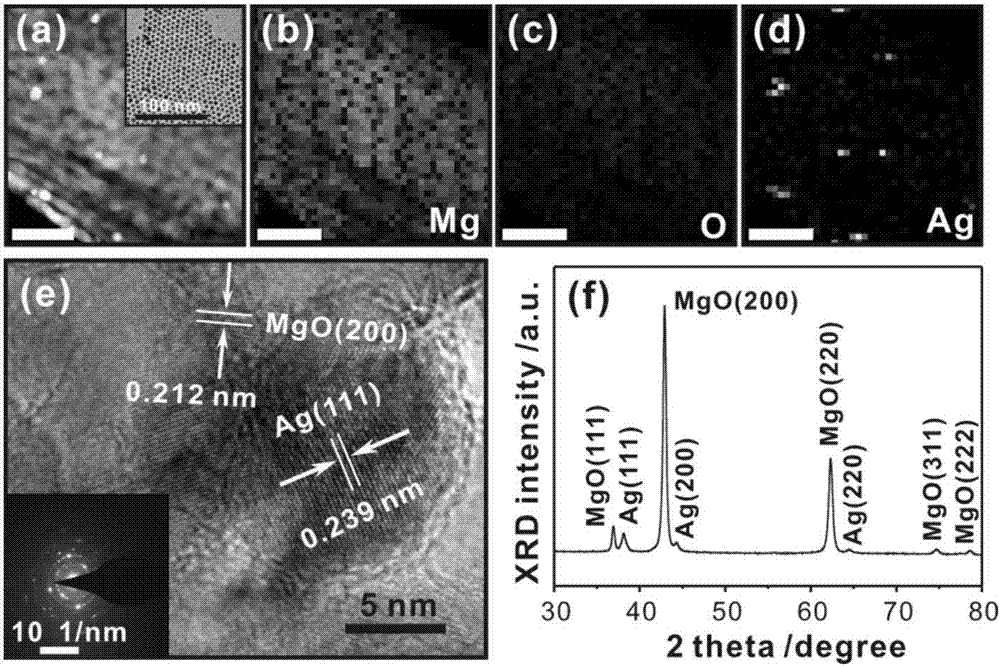

[0107] Examples 1-18 take Ag / MgO catalyst and formaldehyde aqueous solution as biomass solution as an example to illustrate the hydrogen production effect of the present invention, the morphology and structure of Ag / MgO catalyst are as follows figure 1 As shown, the specific surface area of the catalyst is 80m 2 / g, the Ag loading is 0.8wt%. figure 1 a–d are the HAADF-STEM images of Ag / MgO (the embedded image is monodisperse Ag nanoparticles), showing the uniform distribution of Ag nanoparticles on the surface of MgO; figure 1 e is the HR-TEM picture of Ag / MgO (the embedded picture is the selected area electron diffraction pattern), showing the Ag(111) crystal plane and the MgO(200) crystal plane; Figure f is the XRD spectrum of Ag / MgO, showing the Ag and MgO diffraction peaks. HAADF-STEM refers to High Angle Annular Dark Field Image-Scanning Transmission Electron Microscopy, HR-TEM refers to High Power Transmission Electron Microscopy, and XRD refers to X-ray Diffraction....

Embodiment 2-13

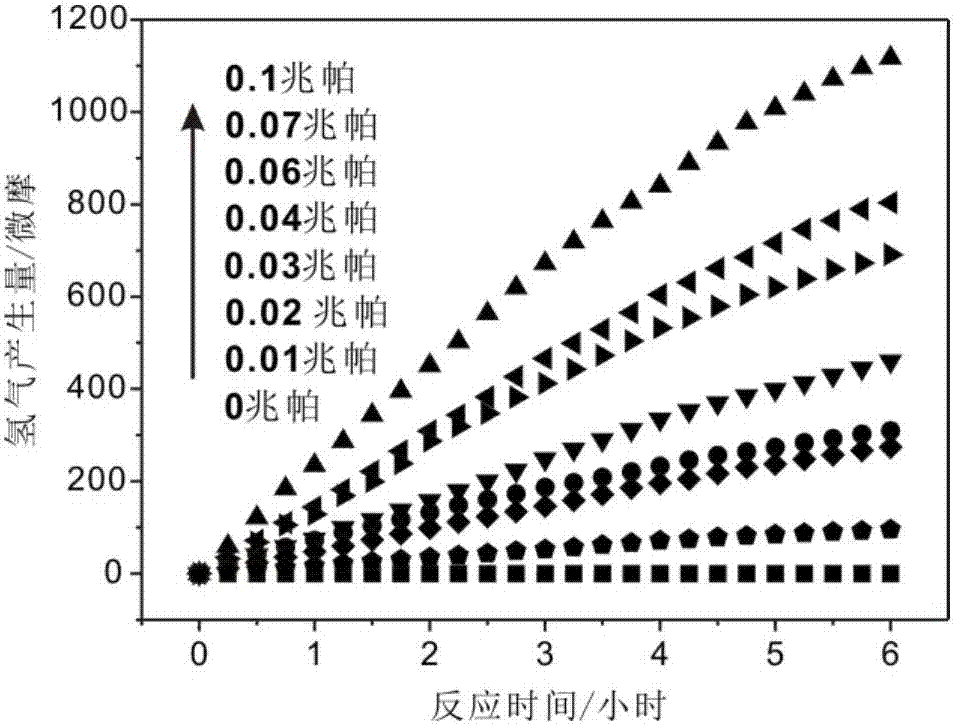

[0110] The results of the oxygen pressure, dissolved oxygen content and hydrogen production in Examples 2-13 are shown in Table 1.

[0111] serial number Gas phase oxygen pressure / MPa Dissolved Oxygen Content / micromolar Hydrogen production / μmol Example 2 0.00 0 0 Example 3 0.01 0.39 96.0 Example 4 0.02 1.24 273.6 Example 5 0.03 1.43 309.7 Example 6 0.04 2.34 460.4 Example 7 0.06 3.77 691.2 Example 8 0.07 4.75 803.1 Example 9 0.10 6.50 1116.5 Example 10 0.20 13.0 734.3 Example 11 0.30 19.5 1095.0 Example 12 0.41 26.0 1180.6 Example 13 0.51 32.5 1254.1

Embodiment 2

[0112] Examples 2-13 studied the effects of different oxygen pressures / concentrations in the hydrogen production system on the Ag / MgO catalyzed formaldehyde aqueous solution to produce hydrogen. Reaction conditions: room temperature (25 ℃), formaldehyde concentration is 1mol / L, volume is 5 milliliters, Ag loading capacity is 0.8wt%, and Ag / MgO quality is 20 milligrams; For the reaction of embodiment 2-10, reaction time is 6 Hour, for the reaction of embodiment 11-13, the reaction time is 2 hours. As can be seen from Examples 2-13, when the oxygen pressure is 0 (embodiment 2), there is almost no hydrogen production, and when the oxygen pressure rises from 0 to 0.51 MPa, the hydrogen production also increases linearly, indicating that oxygen It has a decisive influence on the production of hydrogen. At the same time, by controlling the oxygen pressure, we can also control the rate and total amount of hydrogen produced. from image 3 It can be seen that in the process of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com