Boron-doped carbon nitride modified titanium dioxide composite photoelectrode and preparing method and application of boron doping carbon nitride modified titanium dioxide composite photoelectrode

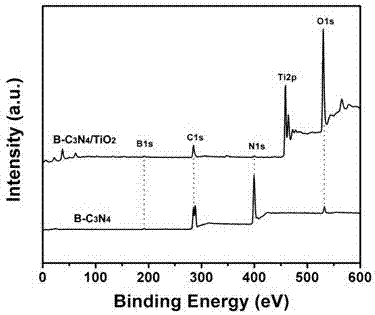

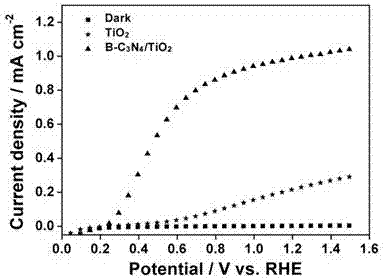

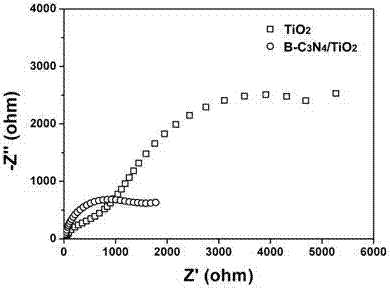

A technology of titanium dioxide and carbon nitride, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve problems such as field barriers, wide band gaps, and low separation efficiency of electrons and holes, so as to suppress recombination, broaden the absorption range, and improve The effect of photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of boron-doped carbon nitride modified titanium dioxide composite photoelectrode, comprising the following steps:

[0025] (1) Add a titanium source compound to hydrochloric acid with a mass fraction of 18.5%, and stir at room temperature until the solution is clear to obtain a mixed solution; the titanium source compound is isopropyl titanate, and the volume ratio of hydrochloric acid to titanium source compound is 3 : 0.07;

[0026] (2) Transfer the mixture obtained in step (1) to a reaction kettle lined with tetrafluoroethylene, and place the FTO conductive glass with the conductive side facing down in the reaction kettle, raise the temperature to 150°C, perform hydrothermal reaction for 12 hours, and cool to room temperature; then take out the conductive glass, wash it with deionized water, dry it with high-purity nitrogen, then put it into the muffle furnace, raise the temperature to 450°C at a heating rate of 5°C / min, and calcined it for 2 hou...

Embodiment 2

[0029] A preparation method of boron-doped carbon nitride modified titanium dioxide composite photoelectrode, comprising the following steps:

[0030](1) Add a titanium source compound to hydrochloric acid with a mass fraction of 15%, and stir at room temperature until the solution is clear to obtain a mixed solution; the titanium source compound is isopropyl titanate, and the volume ratio of hydrochloric acid to titanium source compound is 3 : 0.06;

[0031] (2) Transfer the mixture obtained in step (1) to a reaction kettle lined with tetrafluoroethylene, and place the FTO conductive glass with the conductive side facing down in the reaction kettle, raise the temperature to 140°C, perform a hydrothermal reaction for 15 hours, and cool to room temperature; then take out the conductive glass, wash it with deionized water, dry it with high-purity nitrogen, and then put it into the muffle furnace, raise the temperature to 440°C at a heating rate of 3°C / min, and calcined it for 3 ...

Embodiment 3

[0034] A preparation method of boron-doped carbon nitride modified titanium dioxide composite photoelectrode, comprising the following steps:

[0035] (1) Add a titanium source compound to hydrochloric acid with a mass fraction of 20%, and stir at room temperature until the solution is clear to obtain a mixed solution; the titanium source compound is n-butyl titanate, and the volume ratio of hydrochloric acid to titanium source compound is 3 : 0.07;

[0036] (2) Transfer the mixed liquid obtained in step (1) to a reaction kettle lined with tetrafluoroethylene, and place the FTO conductive glass with the conductive side down in the reaction kettle, raise the temperature to 160°C, conduct a hydrothermal reaction for 8 hours, and cool to room temperature; then take out the conductive glass, wash it with deionized water, dry it with high-purity nitrogen, and then put it into the muffle furnace, raise the temperature to 460°C at a heating rate of 6°C / min, and calcined it for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com