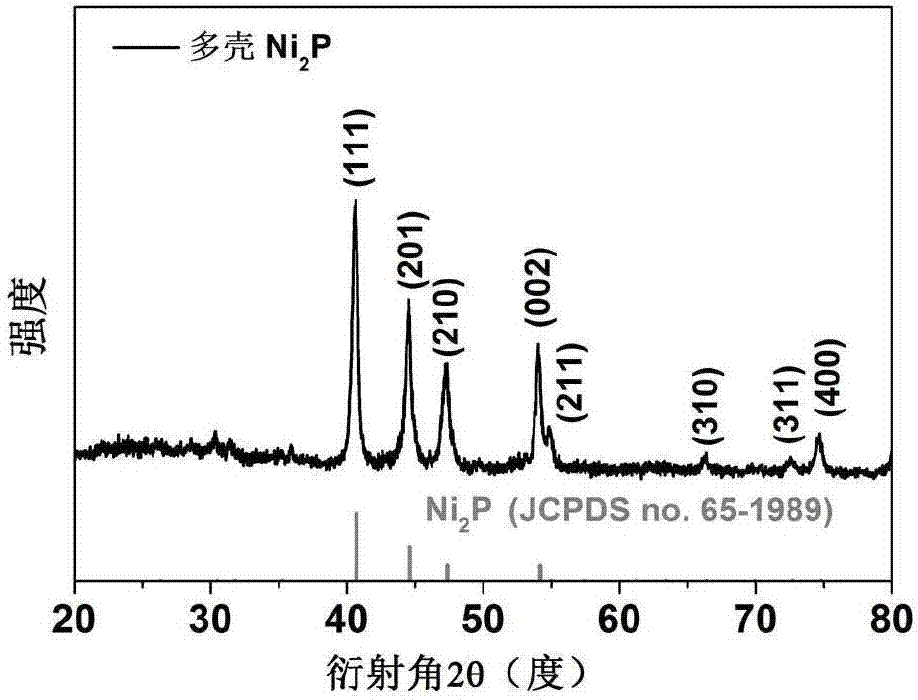

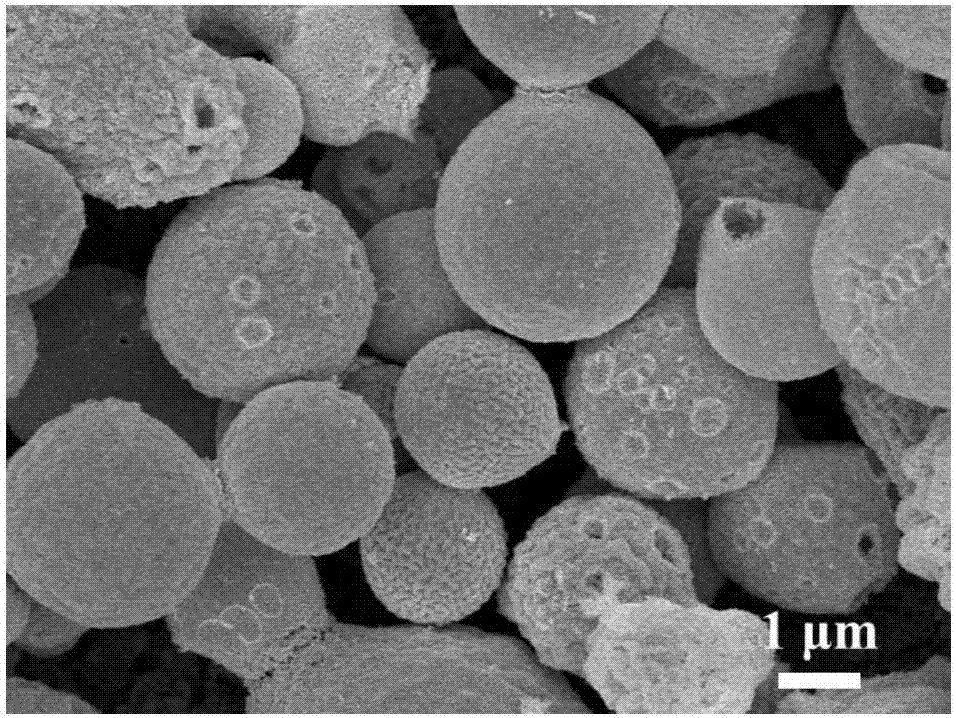

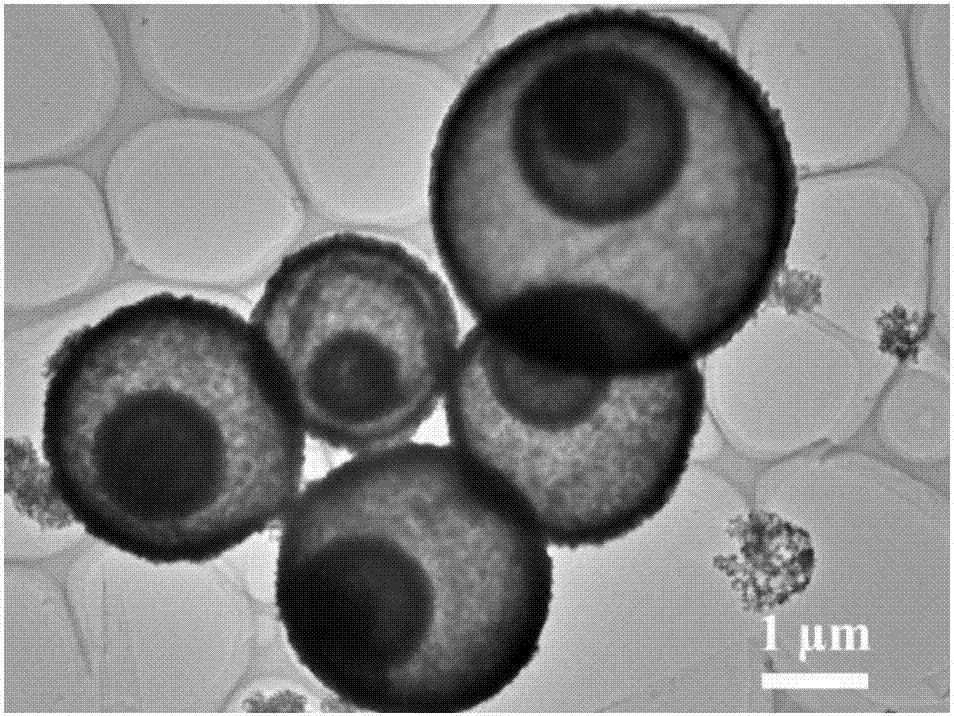

Multi-hole-and-shell nickel phosphide hollow microsphere and preparation method and application thereof

A hollow microsphere, nickel phosphide technology, applied in chemical instruments and methods, phosphide, chemical/physical process, etc., can solve the problem of no report of metal phosphide with multi-shell hollow structure, and achieve rich raw materials and preparation. The method is simple and the effect of improving the electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of the porous multi-shell nickel phosphide hollow microspheres of the present embodiment adopts the method of solid-phase phosphating the precursor of the porous multi-shell nickel oxide hollow microspheres, and the steps are as follows:

[0023] 1) Preparation of porous multi-shell nickel oxide hollow microspheres

[0024] Dissolve 12mmol of urea, 1mmol of nickel chloride hexahydrate and 40mmol of glucose in 100mL of distilled water. After completely dissolving, take 70mL and pour it into an autoclave for 20 hours of hydrothermal reaction at 180°C. After the autoclave is naturally cooled to At room temperature, the obtained black or brown precipitates were collected, washed by alternating centrifugation with distilled water and absolute ethanol several times, and then dried in an oven at 60° C. for 10 hours. The obtained solid powder was calcined in a muffle furnace at 400° C. for 10 hours to obtain multi-shell nickel oxide hollow microspheres, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com