Salted omasum crispness keeping method

A kind of hairy and crispy protection technology, applied in the preservation of food ingredients as anti-microbial, preservation of meat/fish with chemicals, food science, etc., can solve the problems of low water loss rate, corrosion of nutrients, short shelf life, etc. To achieve the effect of improving the loss of nutrients, improving the water absorption capacity and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

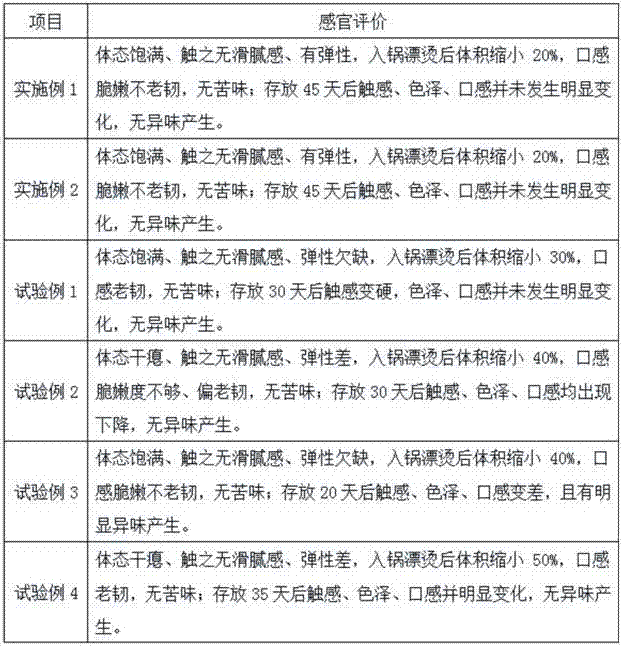

Embodiment 1

[0060] How to protect the crispiness of salted tripe:

[0061] (1) Cleaning: Use clean water to wash the tripe 3 times, drain the clear water for later use;

[0062] (2) Alkaline hair: Add 4‰ of soda and 5‰ of baking soda to the cleaned yellow throat, stir well, and alkali hair for 45 minutes;

[0063] (3) Blanching: Use clean water to rinse the hair belly after alkali hair for 25 minutes, and put the material in boiling water for 25 seconds after washing;

[0064] (4) Cooling: Cool the blanched tripe with stepwise temperature water at 75°C, 55°C, and 35°C in sequence, and finally remove and drain the clear water, and cool naturally to room temperature;

[0065] (5) Enzymolysis: Add the cooled tripe to 4.5 times the amount of papain aqueous solution with a concentration of 0.25% and a temperature of 52.5°C for enzymolysis for 45 minutes. Boil for 15 minutes and cool to 50°C, then remove and drain the water;

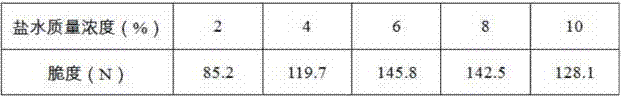

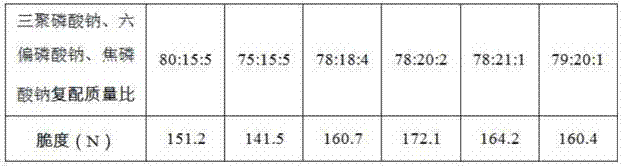

[0066] (6) Soaking in salt water: add the enzymatically hydrolyze...

Embodiment 2

[0070] How to protect crispy salted tripe

[0071] (1) Cleaning: Use clean water to wash the tripe 3 times, drain the clear water for later use;

[0072] (2) Alkaline hair: Add 4‰ of soda and 5‰ of baking soda to the cleaned yellow throat, stir well, and alkali hair for 45 minutes;

[0073] (3) Blanching: Use clean water to rinse the hair belly after alkaline hair for 20 minutes, and put the material in boiling water for 20 seconds after washing;

[0074] (4) Cooling: Cool the blanched tripe with stepwise temperature water at 70°C, 50°C, and 30°C in sequence, and finally remove and drain the clear water, and cool naturally to room temperature;

[0075] (5) Enzymolysis: Add the cooled tripe to 4 times the amount of papain aqueous solution with a concentration of 0.25% and a temperature of 50°C for enzymolysis for 45 minutes. Boil for 15 minutes and cool to 45°C, then remove and drain the water;

[0076] (6) Soaking in salt water: add the enzymatically hydrolyzed hair tripe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com