Preparation method of bone scaffold composite material

A technology of composite materials and bone scaffolds, applied in the field of preparation of bone scaffold composite materials, can solve the problems of high price, economic loss of patients, tissue necrosis, etc., and achieve cost reduction, strong comprehensive bone repair ability, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

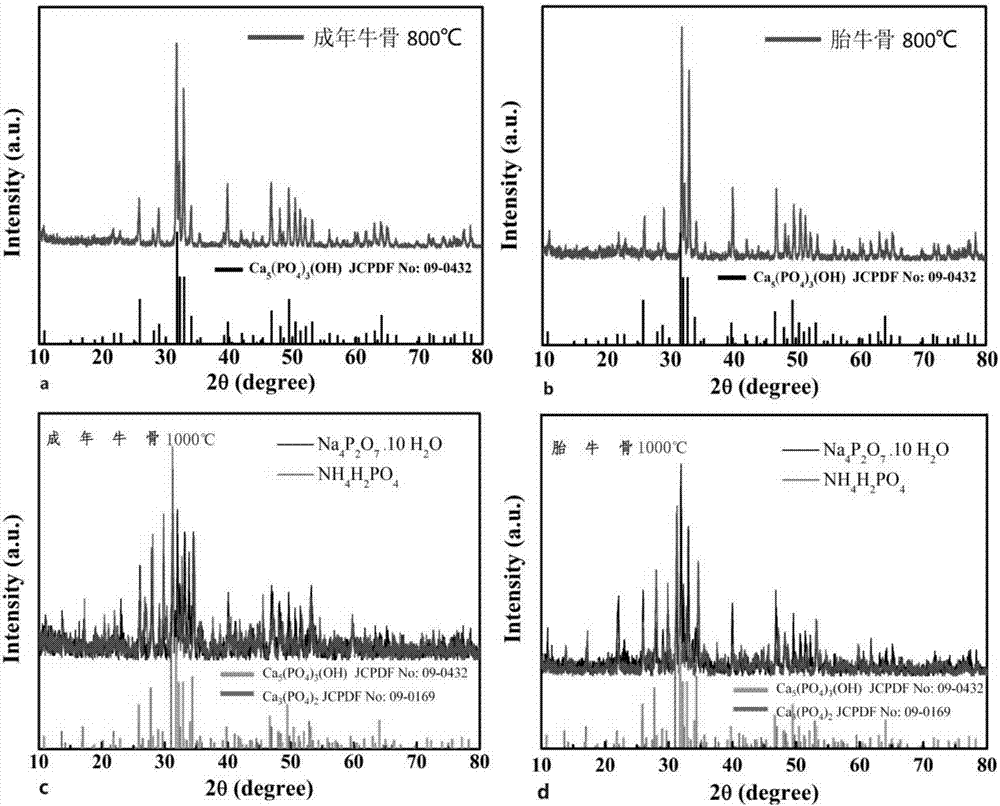

[0044] Calcination of natural bovine cancellous bone by ammonium dihydrogen phosphate method:

[0045] 1.2 Calcination of adult bovine cancellous bone and fetal bovine cancellous bone:

[0046] 1.2.1 Bone preparation and organic matter removal

[0047] Saw off the metaphysis of fresh fetal bovine femur from the femur with a small saw, change the liquid several times with 0.5M / L sodium hydroxide solution under normal pressure, boil to remove grease, and then saw into 10×5×5 (mm 3 ) large and small bone fragments; soak in 0.3M sodium hydroxide solution for 48 hours, and soak in 10% hydrogen peroxide solution for 12 hours.

[0048] 1.2.2 Calcination by sodium pyrophosphate method and ammonium dihydrogen phosphate method

[0049] Step 1: After the filter paper absorbs most of the water, dry it at 80°C for 12 hours; put the dried bone into a muffle furnace for calcination, raise the temperature slowly (5°C / min), maintain it at 800°C for 6 hours, and then follow the furnace Cooli...

Embodiment 2

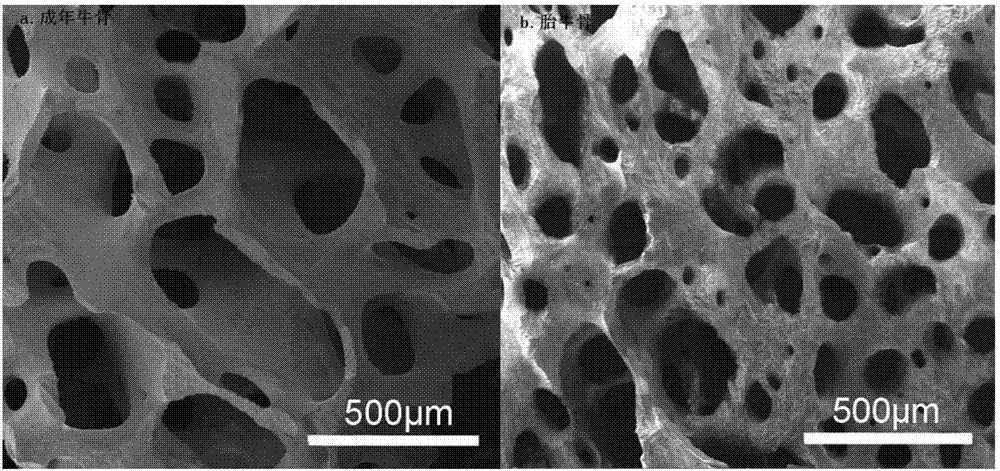

[0063] The relationship between the microstructure and biomechanical properties of bone scaffold materials and bone defect repair:

[0064] After implanted in the body, the bone scaffold material will fully contact with tissues, cells, etc., provide them with growth space, and provide good transporters for metabolites, inflammatory factors, cytokines, etc. during the growth process. Therefore, in addition to the chemical properties of the bone scaffold material itself, the microstructure and mechanical properties of the bone scaffold material are also one of the important factors affecting its osteogenesis. The microstructure such as pore size, porosity and pore distribution and the Young's modulus of the material not only provide the necessary environment for cell adhesion, differentiation and proliferation, but also can significantly affect the response of cells and the degradation of materials during bone repair.

[0065]The pore size of the porous scaffold material is of g...

Embodiment 3

[0125] Preparation of zinc + chitosan surface-modified bone scaffold material and detection of biocompatibility and osteogenesis ability:

[0126] 1.1 Preparation of fetal bovine bone + zinc + chitosan composite material:

[0127] The preparation method of fetal bovine bone is the same as 1.2.1 and 1.2.2 in Example 1. Prepare 500ml of 0.25M ZnCl solution. Use negative pressure suction to fully combine the ZnCl solution with the calcined bone, 60 ° C water bath for 1 hour, and then prepare by low-temperature calcination; prepare 20ml chitosan acetic acid solution (10g / L) and use negative pressure suction to make the chitosan acetic acid solution Full access to Zn-containing 2+ Fetal bovine bone calcined bone, kept at 4°C for 24h; its Zn 2+ The specific detection methods of content and calcium-phosphorus ratio, pore size, surface microstructure observation, porosity detection, compressive strength and Young's modulus are the same as the corresponding methods in the first and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com