Method of preparing inorganic high molecular flocculant polysilicate ferric zinc from copper tailings

A technology of inorganic polymer and polysilicate iron, which is applied in the field of solid waste utilization research, can solve the problems that hinder the sustainable development of copper smelting enterprises, the tailings are not well utilized, and the cost of raw materials is high, so as to achieve good social benefits and economic benefits, enhance the use of added value, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The iron content of the copper tailings used in this embodiment is 40wt%, the silicon dioxide content is 34wt%, and the zinc content is 2wt%.

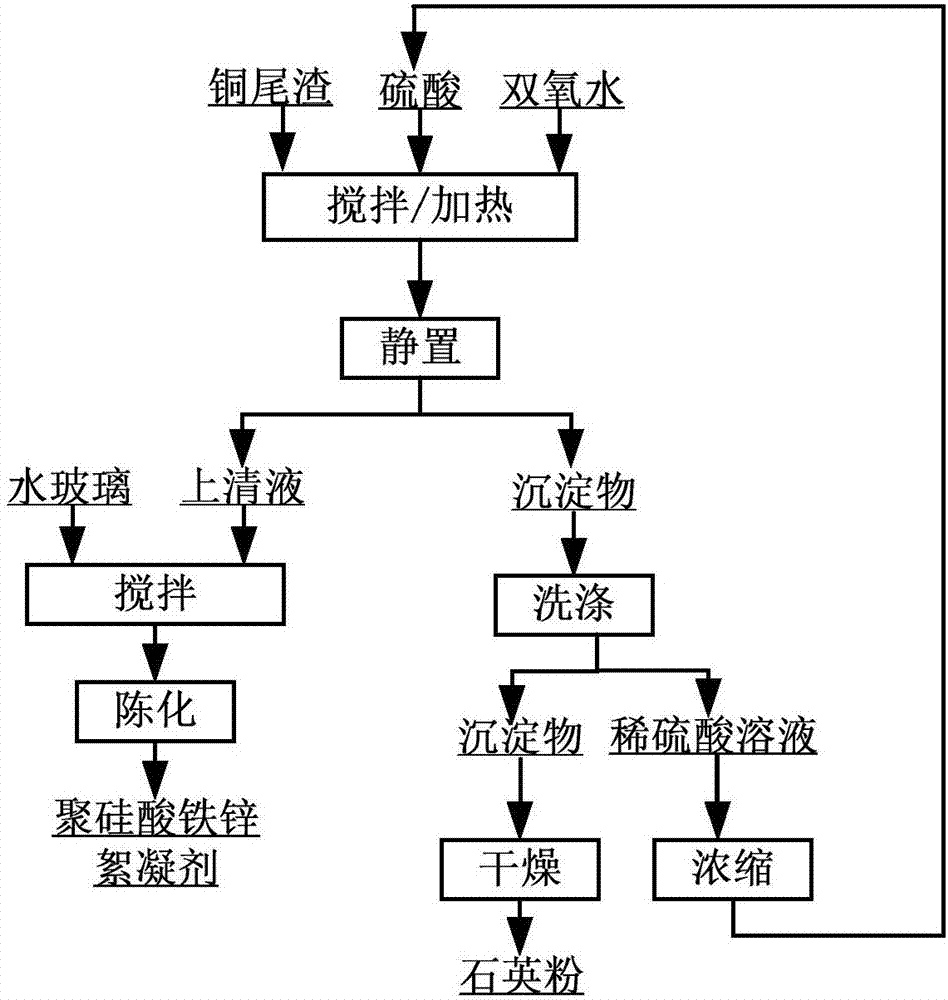

[0033] refer to figure 1 , adding copper tailings to the sulfuric acid solution with a concentration of 4mol / L, the ratio of copper tailings and sulfuric acid solution is 1:5, and then adding copper tailings to the solution at a concentration of 15% of the mass of copper tailings It is 30wt% hydrogen peroxide. Place the above solid-liquid mixed solution in a water bath, stir for 5 hours under the condition of constant temperature heating in a water bath at 100°C to dissolve the copper tailings, and then let it stand for 3 hours to obtain a mixed solution of the lower sediment and the supernatant;

[0034] Dilute the sodium silicate solution (water glass) with water to a concentration of about 15 wt%, and measure the molecular weight of polysilicic acid by viscometry at the same time. pH value to pH=1 to obtain an acidic sodium...

Embodiment 2

[0039] The iron content of the copper tailings used in this embodiment is 40wt%, the silicon dioxide content is 35wt%, and the zinc content is 2.5wt%.

[0040] refer to figure 1 , adding copper tailings to sulfuric acid solution with a concentration of 7mol / L, the ratio of copper tailings to sulfuric acid solution is 1:3, and then adding copper tailings to the solution at a concentration of 10% of the mass of copper tailings It is 40wt% hydrogen peroxide. Place the above solid-liquid mixed solution in a water bath, stir for 3 hours under the condition of constant temperature heating in a water bath at 100°C to dissolve the copper tailings, and then let it stand for 1 hour to obtain a mixed solution of the lower sediment and the supernatant;

[0041] Dilute the sodium silicate solution with water to a concentration of about 15 wt%, and measure the molecular weight of polysilicic acid by viscometry at the same time. pH = 2, the acidic sodium silicate solution is obtained, read...

Embodiment 3

[0046] The iron content of the copper tailings used in this embodiment is 38wt%, the silicon dioxide content is 34wt%, and the zinc content is 1.5wt%.

[0047] refer to figure 1 , adding copper tailings to a sulfuric acid solution with a concentration of 7mol / L, the ratio of copper tailings to sulfuric acid solution is 1:4, and then adding 10% of the mass of copper tailings to the solution It is 38wt% hydrogen peroxide. Place the above solid-liquid mixed solution in a water bath, stir for 3 hours under the condition of constant temperature heating in a water bath at 100°C to dissolve the copper tailings, and then let it stand for 1 hour to obtain a mixed solution of the lower sediment and the supernatant;

[0048] Dilute the sodium silicate solution with water to a concentration of about 15 wt%, and measure the molecular weight of polysilicic acid by viscometry at the same time. pH = 1.5, get an acidic sodium silicate solution, ready to use; under normal circumstances, polys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com