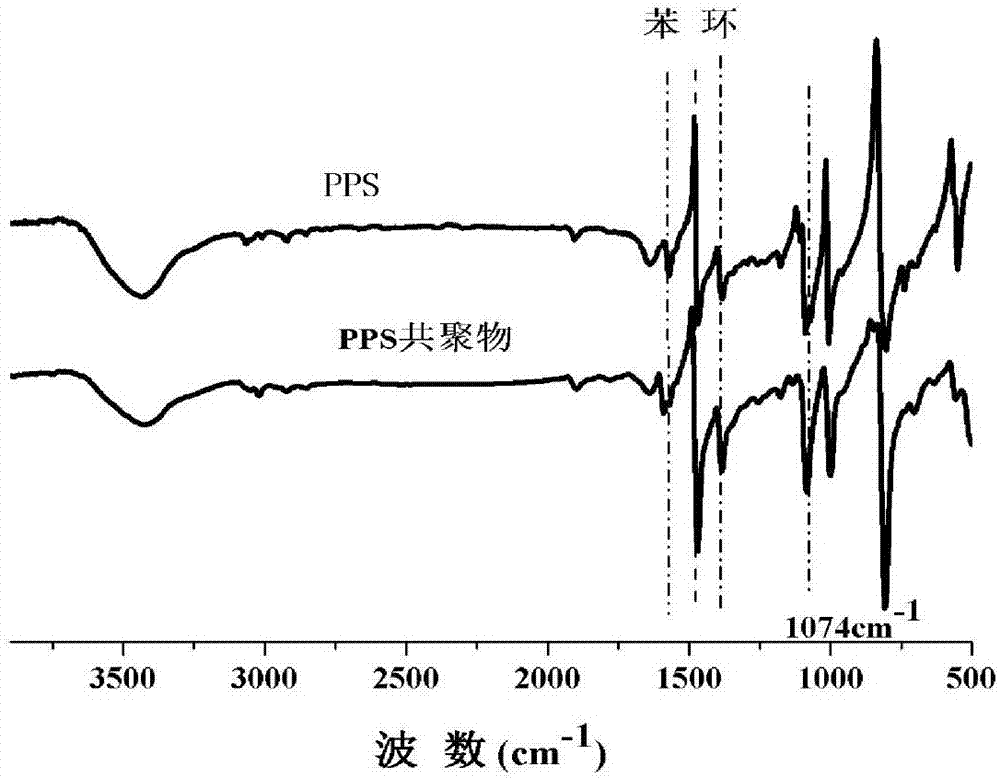

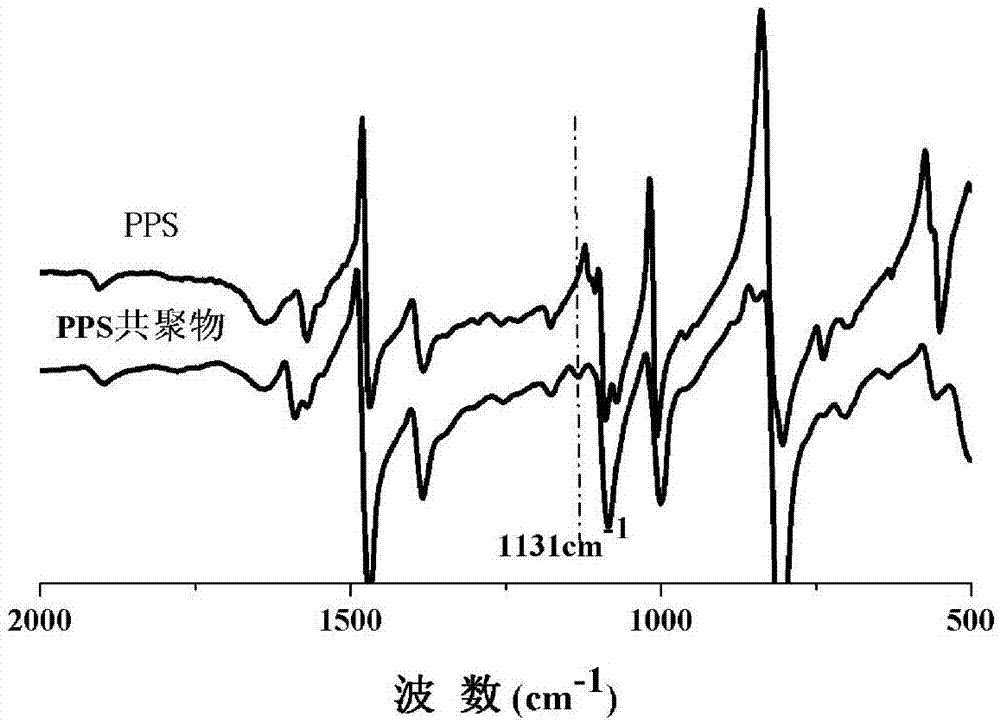

High-temperature-resistant polyarylene sulfide-based copolymer and preparation method thereof

A polyarylene sulfide and copolymer-like technology, applied in the field of polymer synthesis, can solve the problems of low glass transition temperature and melting point, high cost, complex synthesis process, etc., and achieve the improvement of glass transition temperature or melting point, and the method is simple and easy , The effect of short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

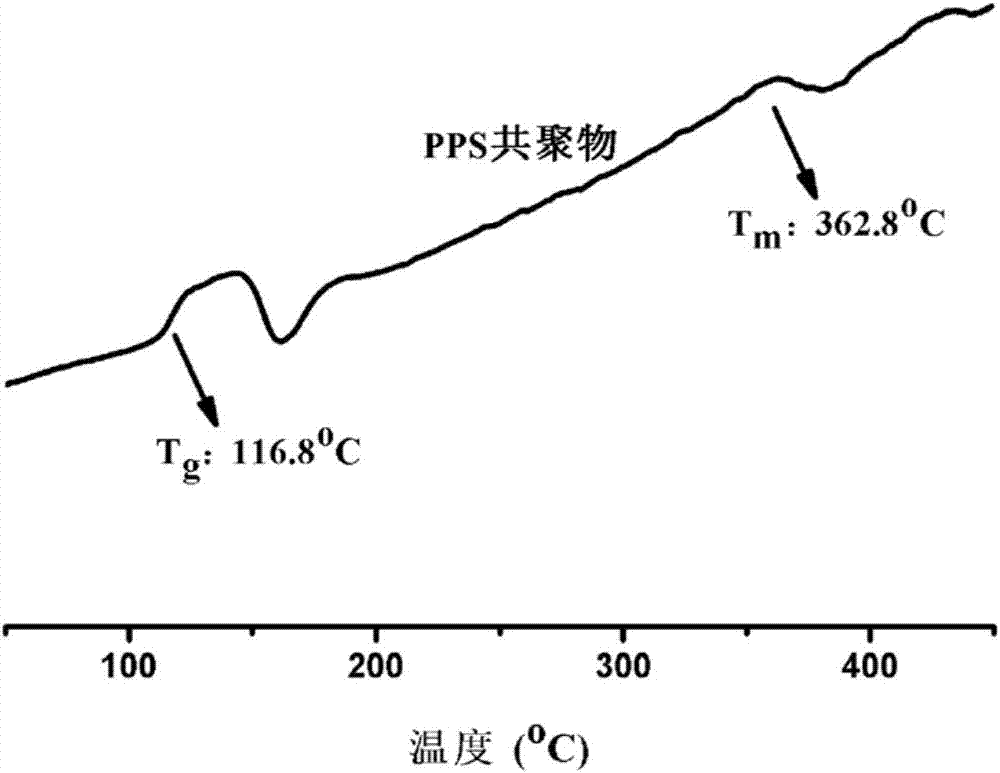

Embodiment 1

[0039] Add 5.0g sodium phosphate, 20.0g caprolactam, 3.0g sodium hydroxide, 65.0g sodium sulfide, and 350g N-methyl-2-pyrrolidone (NMP) into the reaction kettle, heat to 200°C, dehydrate for 0.5h, and cool down Add 66.20 g of 1,4-dichlorobenzene and 9.90 g of 2,6-dichloroquinoline to 160°C, react at 180°C for 1 hour, then react at 200°C for 6 hours; after the reaction is completed, cool to room temperature and add deionized water Wash, filter, and vacuum-dry at 120°C for 12 hours to obtain a white resin with a yield of 89.8%, intrinsic viscosity: 0.283dL / g, glass transition temperature: 103.8°C, melting point: 258.2°C, and thermal decomposition temperature: 490.3°C. Its glass transition temperature increased by 14.4°C compared with pure PPS resin.

Embodiment 2

[0041]Add 10.0g sodium benzoate, 10.0g 6-aminocaproic acid, 8.0g sodium hydroxide, 65.0g sodium sulfide, and 350g N-methyl-2-pyrrolidone (NMP) into the reaction kettle, heat to 200°C, and dehydrate 0.5h, after cooling down to 100°C, add 66.20g of 1,4-dichlorobenzene and 9.90g of 2,4-dichloroquinoline, react at 240°C for 4h, then react at 280°C for 1h. After the reaction, cool to room temperature, add deionized water to wash, filter, and vacuum-dry at 120°C for 12 hours to obtain a white resin, yield: 92.8%, intrinsic viscosity: 0.281dL / g, glass transition temperature: 103.2°C, melting point : 255.4°C, thermal decomposition temperature: 488.5°C. Its glass transition temperature increased by 13.8°C compared with pure PPS resin.

Embodiment 3

[0043] 10.0g lithium acetate, 10.0g polyethylene glycol-600, 8.0g potassium hydroxide, 65.0g sodium sulfide, 400g 1,3-dimethyl-2-imidazolidinone (DMI), were added to the reaction kettle, Heat to 200°C, dehydrate for 0.5h, cool down to 140°C, add 58.80g of 1,4-dichlorobenzene and 28.7g of 2,4-dibromoquinoline, react at 200°C for 4h, then react at 240°C for 2h. After the reaction, cool to room temperature, add deionized water to wash, filter, and vacuum dry at 120°C for 12 hours to obtain a white resin with a yield of 88.6%, intrinsic viscosity: 0.288dL / g, glass transition temperature: 113.2°C, melting point : 254.4°C, thermal decomposition temperature: 492.3°C. Its glass transition temperature increased by 23.8°C compared with pure PPS resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com