Liquid enzyme preparation and method for preparing liquid enzyme preparation

A liquid enzyme and preparation technology, which is applied in the field of food additives and enzyme preparations, can solve problems such as air leakage, uneven powder distribution, cumbersome nitrogen filling operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

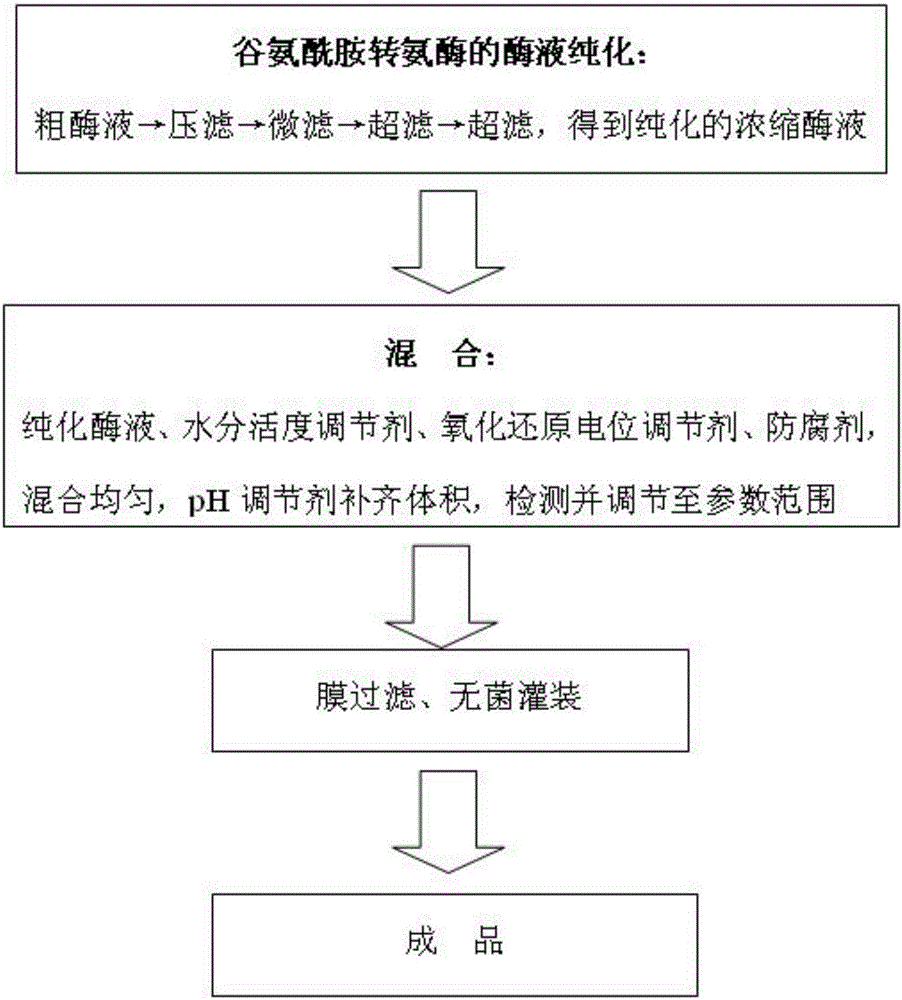

[0107] The preparation of transglutaminase crude liquid uses microbial fermentation method, can refer to patent (patent publication number: EP0379606B1): take Moyuan Streptomyces mobaraensis (Streptomyces mobaraensis) as starting bacterial strain, pick a few well-growing bacterium colonies with inoculating loop and inoculate in On a slant medium, culture at a constant temperature of 30°C for 7 days. The activated strains are then inserted into the seed medium, cultivated at 30°C for 48 hours, added to the fermentation medium according to 10% inoculum, and cultivated at 30°C for 48-72 hours to obtain a crude transglutaminase, enzyme The purification and concentration of the crude liquid is carried out according to the following steps:

[0108] 1) Press filter: pore size 1μm, operating pressure 0.20MPa, temperature 20°C, take the filtrate;

[0109] 2) Microfiltration: the pore size is 0.25μm, the operating pressure is 0.25MPa, the temperature is 20°C, and the filtrate is taken;...

Embodiment 2

[0114] The crude liquid of transglutaminase was prepared by enzyme powder dissolving method, weighed a certain amount of pure water, placed in a capacity with stirring function, and the enzyme activity was 5000-8000u / ml of transglutaminase powder (Shanghai Qingrui Foodstuffs Co., Ltd. Enzyme powder produced by Science and Technology Co., Ltd.) was added slowly, and stirred while adding to obtain a certain concentration of enzyme liquid, which was sterilized by microfiltration to obtain a clear transglutaminase solution with an enzyme activity of 2500u / ml and an enzyme activity of 2500u / ml transglutaminase purified and concentrated enzyme solution. The detected pH is 6.30, the water activity is 0.95, and the oxidation-reduction potential is 58mv, and it is ready for use.

Embodiment 3

[0116] A preparation method of liquid transglutaminase, the total weight of the liquid enzyme is 1000ml, the preparation method is as follows, weighed according to the ingredients list 11,

[0117] Table 11. Preparation of a liquid transglutaminase

[0118]

[0119] Weigh the materials in the formula, mix evenly, and filter through a 0.1 micron sterile membrane to obtain a light yellow solution. The redox potential is -100mv, the water activity is 0.79, the pH is 6.0, and the enzyme activity is 498.1u / ml. Fill in 10 bottles of 100mL PET opaque bottles, and finally prepare the liquid transglutaminase preparation. After storing at room temperature for 180 days, observe the enzyme preparation of this formula, detect the enzyme activity, and calculate the preservation rate of the enzyme activity. GB4789.2-2010 National Food Safety Standard "Determination of Total Bacterial Colony in Food Microbiological Examination", GB 4789.3 National Food Safety Standard "Coliform Count in Fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water activity | aaaaa | aaaaa |

| water activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com