Compounding brightener for copper plating and preparation method thereof

A technology of brightener and copper plating, which is applied in the field of compound brightener for copper plating and its preparation, which can solve the problems of poor bonding between copper layer and iron substrate, non-dense crystal grain composition of copper plating layer, and low cathode current efficiency, etc. problem, to achieve the effect of inhibiting rapid deposition, good toughness, eliminating pitting and pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Take 15g of sodium phenyl polydithiodipropane sulfonate, 0.5g of 2-mercaptobenzothiazole, and 0.5g of ethylenethiourea, add it to 100mL of 95% ethanol solution, stir at 300r / min for 20min, then add 50g polyethylene glycol P1000, 50g sodium dodecylsulfonate, 0.1g lanthanum nitrate, 1L deionized water, continue to stir for 20min, and discharge to obtain a compound brightener for copper plating.

[0024] Add the compound brightener for copper plating prepared by the present invention into the electroplating solution in the aqueduct, control the addition amount to 0.8mg / L, stir and mix for 15min, then control the temperature in the aqueduct to 45°C, and the current density to 1A / dm 2 , Put the plated parts into the aqueduct for electroplating for 10 minutes.

example 2

[0026] Take 20g of sodium phenyl polydithiodipropane sulfonate, 0.8g of 2-mercaptobenzothiazole, and 0.8g of 2-tetrahydrothiazolthione, add it to 150mL of 97% ethanol solution, and stir at 350r / min for 25min. Then add 75g of polyethylene glycol P6000, 75g of OP-21, 0.3g of lanthanum nitrate, 2L of deionized water, continue stirring for 25min, and discharge to obtain a compound brightener for copper plating.

[0027] Add the compound brightener for copper plating prepared by the present invention into the electroplating solution in the aqueduct, control the addition amount to 0.9 mg / L, stir and mix for 18 minutes, then control the temperature in the aqueduct to 48°C, and the current density to 6A / dm 2 , Put the plated parts into the aqueduct and electroplate for 15 minutes.

example 3

[0029] Take 25g of sodium phenyl polydithiodipropane sulfonate, 1.0g of 2-tetrahydrothiazolethione, and 1.0g of ethylenethiourea, add it to 200mL of ethanol solution with a mass fraction of 98%, stir at 400r / min for 30min, and then add 100g Polyethylene glycol P6000, 100g aliphatic amine polyoxyethylene ether, 0.5g yttrium nitrate, 2L deionized water, continue stirring for 30min, and discharge to obtain a compound brightener for copper plating.

[0030] Add the compound brightener for copper plating prepared by the present invention into the electroplating solution in the aqueduct, control the addition amount to 1.0mg / L, stir and mix for 20min, then control the temperature in the aqueduct to 50°C, and the current density to 10A / dm 2 , Put the plated parts into the aqueduct for electroplating for 20 minutes.

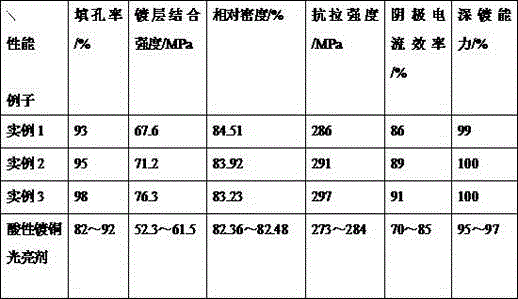

[0031] The coating on the surface of the composite brightener for copper plating obtained in the above embodiments is detected and compared with the coating on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com