Building thermal insulation material and preparation method thereof

A technology of building thermal insulation and gelling materials, applied in the field of building materials, to achieve the effects of stable chemical properties, strong adsorption, and elimination of smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

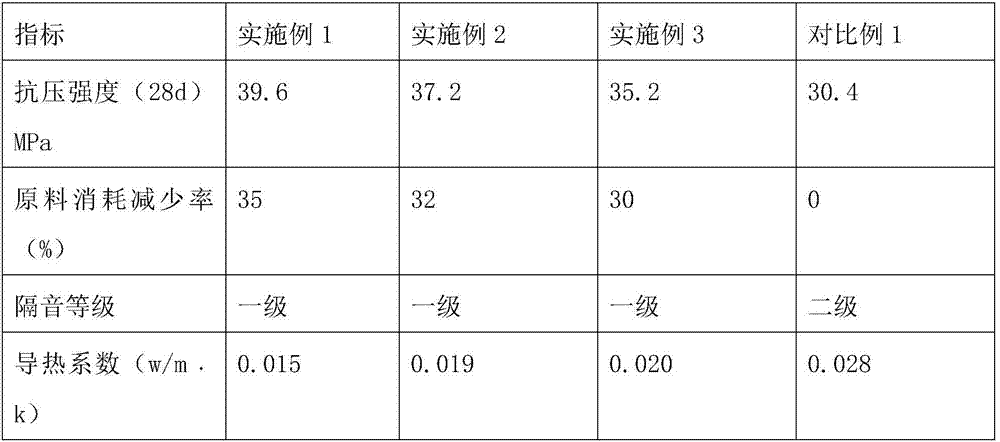

Examples

Embodiment 1

[0040] A building insulation material, comprising the following raw materials in parts by weight: diatomite 40kg, expanded perlite 17.5kg, vermiculite 25kg, soft porcelain 20kg, lime calcium powder 26kg, quartz sand 17.5kg, fly ash 1kg, polyethylene foam 17kg of plastic, 20kg of negative ion powder for construction, 12.5kg of stearic acid, 8kg of sodium formate, 11kg of inorganic fiber, 7kg of cementitious material, 12kg of filler, 1.5kg of activator, 0.5kg of water reducing agent and 6kg of water.

[0041] The building thermal insulation material prepared under the raw material formula has reached the best in terms of energy saving, environmental protection, sound insulation, compressive strength and thermal insulation.

[0042] Diatomite is added to the raw material, which has the advantages of sound insulation, thermal insulation, non-combustibility, strong adsorption, stable chemical properties, light weight, dehumidification, deodorization and air purification.

[0043]So...

Embodiment 2

[0059] A building insulation material, comprising the following raw materials in parts by weight: 30kg of diatomite, 15kg of expanded perlite, 20kg of vermiculite, 15kg of soft porcelain, 22kg of ash calcium powder, 15kg of quartz sand, 0.5kg of fly ash, polyethylene foam 12kg, negative ion powder for construction 15kg, stearic acid 10kg, sodium formate 5kg, inorganic fiber 10kg, gelling material 5kg, filler 10kg, activator 1kg, water reducer 0.3kg and water 4kg.

[0060] Diatomite is added to the raw material, which has the advantages of sound insulation, thermal insulation, non-combustibility, strong adsorption, stable chemical properties, light weight, dehumidification, deodorization and air purification.

[0061] Soft porcelain is added to the raw materials. Soft porcelain is made of urban construction waste soil, cement waste blocks, porcelain slag and stone powder, etc., which achieves the current recycling of waste. Here, soft porcelain is used in building insulation mat...

Embodiment 3

[0077] A building insulation material, comprising the following raw materials in parts by weight: diatomite 50kg, expanded perlite 20kg, vermiculite 30kg, soft porcelain 25kg, lime calcium powder 30kg, quartz sand 20kg, fly ash 1.5kg, polyethylene foam 22kg, negative ion powder for construction 25kg, stearic acid 15kg, sodium formate 11kg, inorganic fiber 12kg, gelling material 9kg, filler 14kg, activator 2kg, water reducer 0.7kg and water 8kg.

[0078] Diatomite is added to the raw material, which has the advantages of sound insulation, thermal insulation, non-combustibility, strong adsorption, stable chemical properties, light weight, dehumidification, deodorization and air purification.

[0079] Soft porcelain is added to the raw materials. Soft porcelain is made of urban construction waste soil, cement waste blocks, porcelain slag and stone powder, etc., which achieves the current recycling of waste. Here, soft porcelain is used in building insulation materials to achieve t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com