Fuel cell catalyst using graphene/fullerene three-dimensional composite material as carrier and preparation and application thereof

A composite material, fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve problems such as less research, and achieve high catalytic activity, excellent performance, and good catalyst performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Synthesis of fullerene pyrrolidine derivatives.

[0036] In a 100ml round-bottomed flask, add 72mg of C60, 36mg of p-nitrobenzaldehyde, 180mg of sarcosine and 45ml of toluene, reflux at 115°C for 14 hours under nitrogen protection, cool and filter, and use a vacuum rotary evaporator for the filtrate After concentration, it was purified by silica gel column chromatography, and the eluent was toluene / ethanol (10:1). The obtained product was characterized by MALDI-TOF-MS, and a series of mass spectrum peaks were observed at molecular weights of 834-1119, corresponding to 2-7 pyrrolidinyl substituents respectively.

Embodiment 2

[0038] Preparation of three-dimensional self-assembled structures of graphene oxide-fullerene.

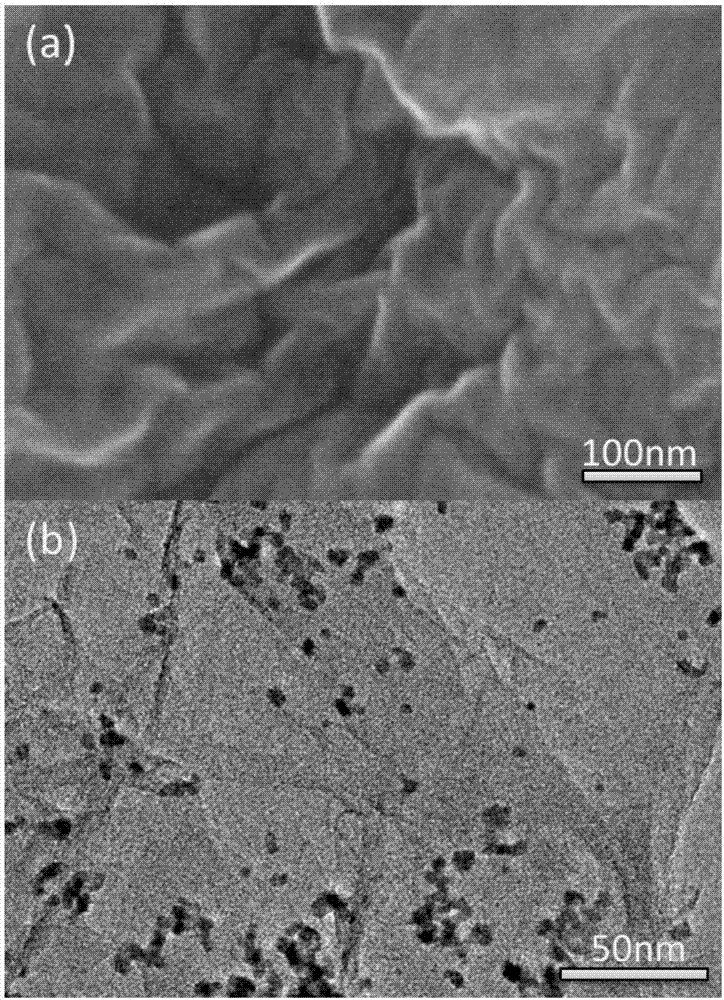

[0039] Mix 20ml of graphene oxide aqueous solution (0.5mg / ml) with 10ml of ethanol solution of fullerene pyrrolidine derivatives (0.5mg / ml) by ultrasonication for 5 minutes, and let stand for 4 hours; centrifuge the formed precipitate and then water Ultrasonic dispersion, drop directly on a clean silicon wafer, and observe with a S-4800 scanning electron microscope, the three-dimensional self-assembled structure of graphene oxide-fullerene ( figure 1 a).

Embodiment 3

[0041] Preparation of graphene-fullerene three-dimensional composite supported palladium catalyst.

[0042] Ultrasonically disperse 20mg of graphene oxide-fullerene three-dimensional composite material in 20ml of water, add 2ml of palladium chloride aqueous solution (2mg / ml) and ultrasonic for 30 minutes, transfer to a hydrothermal reaction kettle, add 80μl of hydrazine hydrate The reaction was carried out at 95°C for 4 hours. After cooling and centrifuging, the precipitate was washed three times with distilled water, and then placed in a vacuum drying oven at 40-50° C. for 24 hours to obtain a graphene-fullerene three-dimensional composite supported palladium catalyst. Characterized by TEM, it can be seen that the catalyst nanoparticles are uniformly dispersed on the surface of the graphene-fullerene three-dimensional composite ( figure 1 b).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com