Method for preparing sugarcane juice beverages and sugarcane syrups by using pressed sugarcane juice of sugar refinery

A sugarcane syrup, sugarcane juice technology, applied in the application, the function of food ingredients, the preservation of food ingredients as anti-microbial, etc. Color change, reduce energy consumption, restore color and flavor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

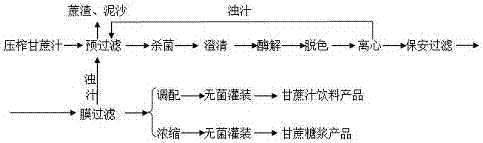

Image

Examples

Embodiment 1

[0037] The method for preparing sugarcane juice beverage and sugarcane syrup by pressing sugarcane juice in a sugar factory includes pretreatment, centrifugal separation, filtration, blending and concentration, and filling. The specific process steps are:

[0038] (1) Preprocessing:

[0039] A, pre-filtering: the sugar cane juice squeezed by the sugarcane sugar factory is pre-filtered with 200 mesh sieves to remove bagasse and silt;

[0040] B. Sterilization: Into the pre-filtered sugarcane juice, pass into the ozone with a concentration of 8mg / L in water, and sterilize for 10min under the cooperation of ultrasonic waves with a frequency of 25KHz and a power of 50W;

[0041] C. Clarification: Add 20 mg / mL chitosan flocculant to the sterilized sugarcane juice, the dosage is 20 mg / L, stir to make it produce flocculation, enter the rapid settler for sedimentation and clarification, and take the supernatant; The preparation method of the polysaccharide flocculant is as follows: a...

Embodiment 2

[0051] The method for preparing sugarcane juice beverage and sugarcane syrup by pressing sugarcane juice in a sugar factory includes pretreatment, centrifugal separation, filtration, blending and concentration, and filling. The specific process steps are:

[0052] (1) Preprocessing:

[0053] A, pre-filtering: the sugar cane juice squeezed by the sugarcane sugar factory is pre-filtered with 100 mesh sieves, and bagasse and silt are removed;

[0054] B. Sterilization: Into the pre-filtered sugarcane juice, the ozone concentration in water is 10mg / L, and under the cooperation of ultrasonic waves with a frequency of 25KHz and a power of 50W, the bacteria are sterilized for 8 minutes;

[0055] C. Clarification: Add 40 mg / mL chitosan flocculant to the sterilized sugarcane juice, the dosage is 30 mg / L, stir to make it produce flocculation, enter the rapid settler for sedimentation and clarification, and take the supernatant; The preparation method of the polysaccharide flocculant is...

Embodiment 3

[0065] The method for preparing sugarcane juice beverage and sugarcane syrup by pressing sugarcane juice in a sugar factory includes pretreatment, centrifugal separation, filtration, blending and concentration, and filling. The specific process steps are:

[0066] (1) Preprocessing:

[0067] A, pre-filtering: the sugar cane juice squeezed by the sugarcane sugar factory is pre-filtered with a 300-order net to remove bagasse and silt;

[0068] B. Sterilization: Into the pre-filtered sugarcane juice, pass into the ozone with a concentration of 12mg / L in water, and sterilize for 6 minutes under the cooperation of ultrasonic waves with a frequency of 25KHz and a power of 50W;

[0069] C. Clarification: Add 50 mg / mL chitosan flocculant to the sterilized sugarcane juice, the dosage is 15 mg / L, stir to make it produce flocculation, enter the rapid settler for sedimentation and clarification, and take the supernatant; The preparation method of the polysaccharide flocculant is as follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com