TiO2/GQDs/NiS heterojunction photoanode and preparation method thereof

A photoanode and heterojunction technology, applied in the field of photoelectrochemical materials and photocatalysis, to achieve good stability, strong photoelectrochemical response, and excellent light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

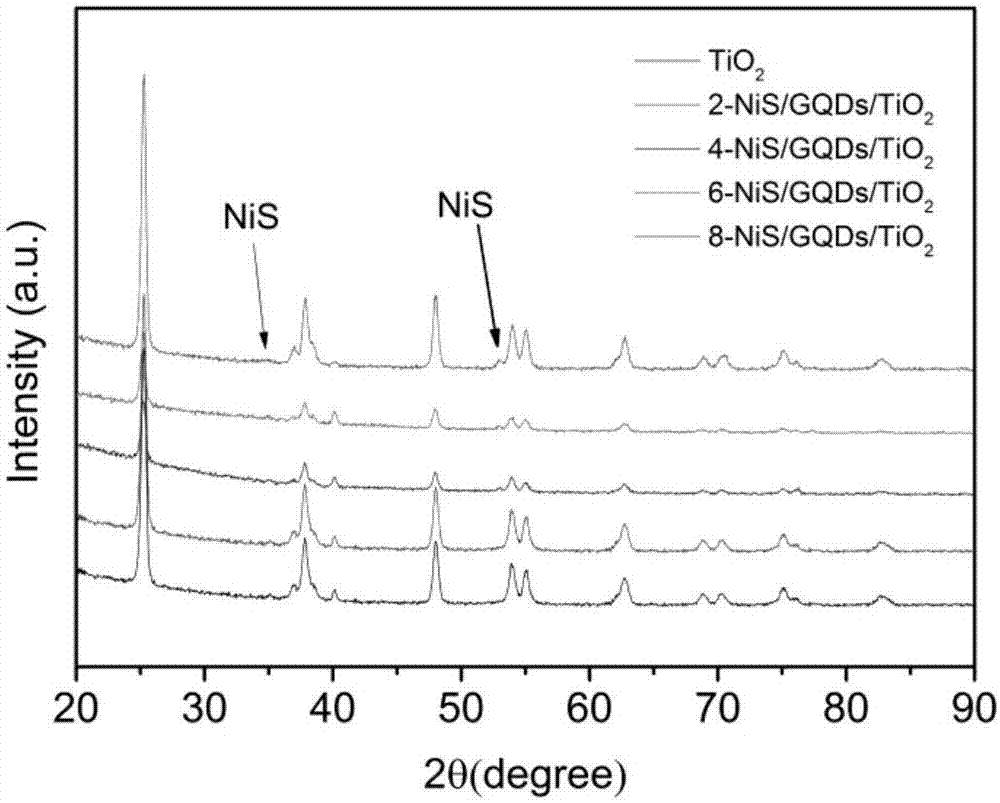

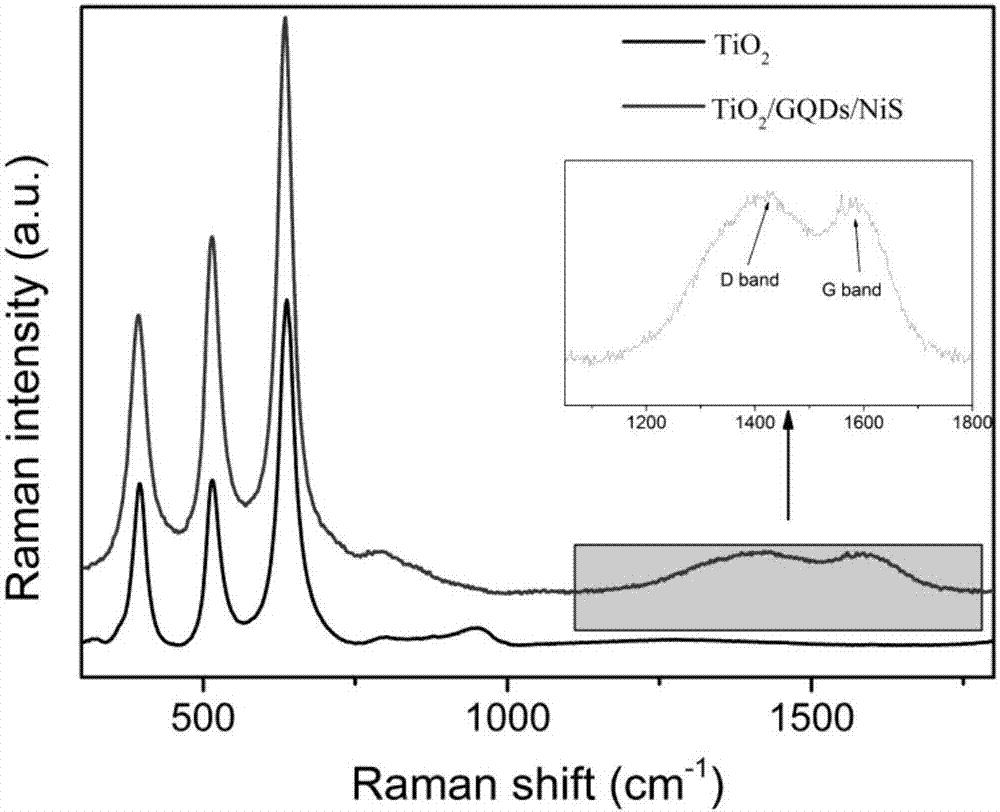

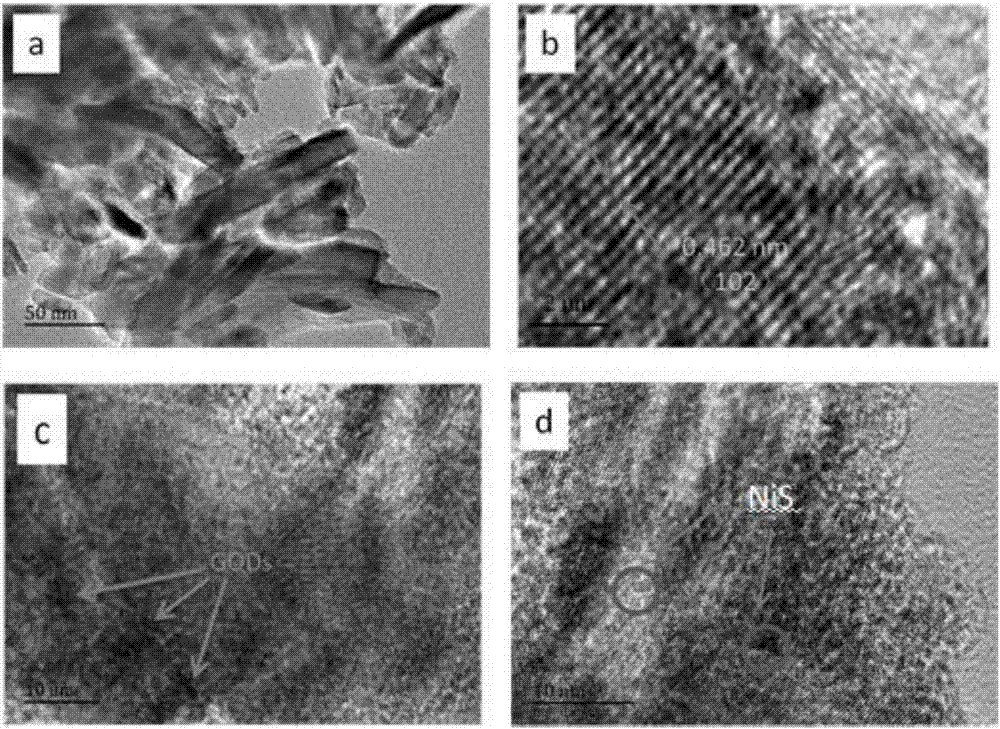

[0019] (1) Synthesis of TiO by anodic oxidation 2 For nanotubes, the titanium sheet was sonicated in acetone, ethanol, and distilled water for 15 minutes respectively. The electrolyte is 0.3wt% ammonium fluoride, 2wt% distilled water, and 100mL of ethylene glycol. Add 10mL of graphene quantum dots to the electrolyte, set the output voltage of the DC stabilized power supply to 60V, and anodize for 2 hours Finish. Finally, rinse the anodized test piece with distilled water, dry it with cold wind, and store it for processing.

[0020] (2) Immerse the photoanode prepared in step (1) in 0.03M ethanolic nickel nitrate solution for 2min, then rinse off the excess and loose adsorbed ions on the surface of the sample with ethanol, and then immerse the photoelectrode in 0.03M sodium sulfide aqueous solution Medium 5min. Rinse the sample test piece with distilled water, dry it with cold wind, repeat this step 5 times, and save it for processing.

[0021] (3) Place the sample test pie...

Embodiment 2

[0024] (1) Synthesis of TiO by anodic oxidation 2 For nanotubes, the titanium sheet was sonicated in acetone, ethanol, and distilled water for 15 minutes respectively. The electrolyte is 0.3wt% ammonium fluoride, 2wt% distilled water, and 100mL of ethylene glycol. Add 15mL of graphene quantum dots to the electrolyte, set the output voltage of the DC stabilized power supply to 60V, and anodize for 2 hours Finish. Finally, rinse the anodized test piece with distilled water, dry it with cold wind, and store it for processing.

[0025] (2) Immerse the photoanode prepared in step (1) in 0.03M ethanolic nickel sulfate solution for 2min, then rinse off the excess and loose adsorbed ions on the surface of the sample with ethanol, and then immerse the photoelectrode in 0.03M potassium sulfide aqueous solution Incubate for 5 minutes, then rinse the sample test piece with distilled water, dry it with cold wind, repeat this step 3 times, dry it, and save it for processing.

[0026] (3)...

Embodiment 3

[0029] (1) Synthesis of TiO by anodic oxidation 2 For nanotubes, the titanium sheet was sonicated in acetone, ethanol, and distilled water for 15 minutes respectively. The electrolyte is 0.3wt% ammonium fluoride, 2wt% distilled water and 100mL of ethylene glycol. Add 20mL of graphene quantum dots to the electrolyte, set the output voltage of the DC stabilized power supply to 60V, and anodize for 2 hours Finish. Finally, rinse the anodized test piece with distilled water, dry it with cold wind, and store it for processing.

[0030] (2) Immerse the photoanode prepared in step (2) in 0.03M ethanolic nickel chloride solution for 4min, then rinse off the excess and loose adsorbed ions on the surface of the sample with ethanol, and then immerse the photoelectrode in 0.03M ammonium sulfide After soaking in the aqueous solution for 6 minutes, rinse the sample test piece with distilled water, dry it with cold air, repeat this step 8 times, and save it for processing.

[0031] (3) Pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com