Synthetic method of cobaltosic oxide-loaded copper oxide nanorod

A technology of copper oxide nanorods and cobalt tetroxide, which is applied in cobalt oxide/cobalt hydroxide, copper oxide/copper hydroxide, nanotechnology for materials and surface science, etc., can solve the problem of high overpotential and high working potential of hydrogen evolution reaction , high specific capacity and other issues, to achieve the effect of improved catalytic performance, short time consumption and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

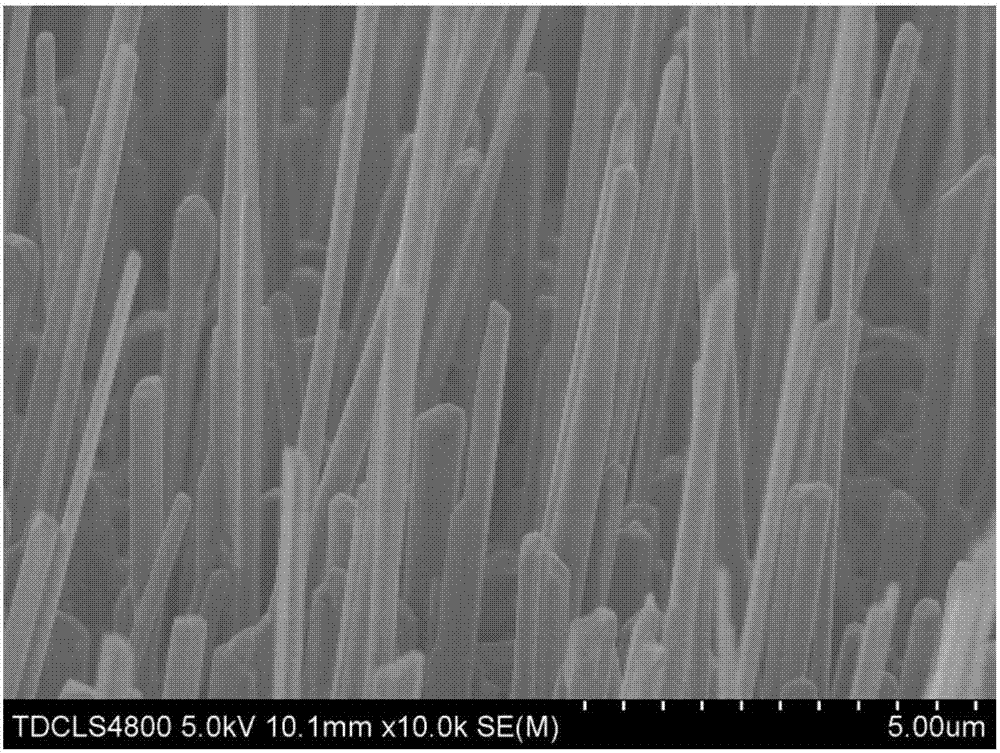

[0023] Soak the surface of the pure copper mesh with hydrochloric acid or ethanol and ultrasonically clean it with deionized water, dry it for later use; place the pure copper mesh in a ceramic ark and heat it in a box-type electric furnace at a heating temperature of 500°C for 5 hours. CuO nanorods grown on copper grids were prepared after cooling in the furnace.

[0024] The prepared copper mesh grown with CuO nanorods was placed in Co(NO 3 ) 2 , NH 4 F, potassium sodium tartrate (C 4 h 4 QUR 6 -4H 2 O) and urea (CO(NH 2 ) 2 ) in the mixed solution of water and ethylene glycol, carry out hydrothermal reaction in the reactor. Among them, water, ethylene glycol, Co(NO 3 ) 2 , NH 4 F, potassium sodium tartrate (C 4 h 4 QUR 6 -4H 2 O) and urea (CO(NH 2 ) 2 ) is 8.4:2.7:0.35:0.5:0.2:1.5, the filling ratio of the mixed solution to the reactor is 2:1; the heating temperature is 110°C; the heating time is 5h.

[0025] The above reaction product was washed with deio...

Embodiment 2

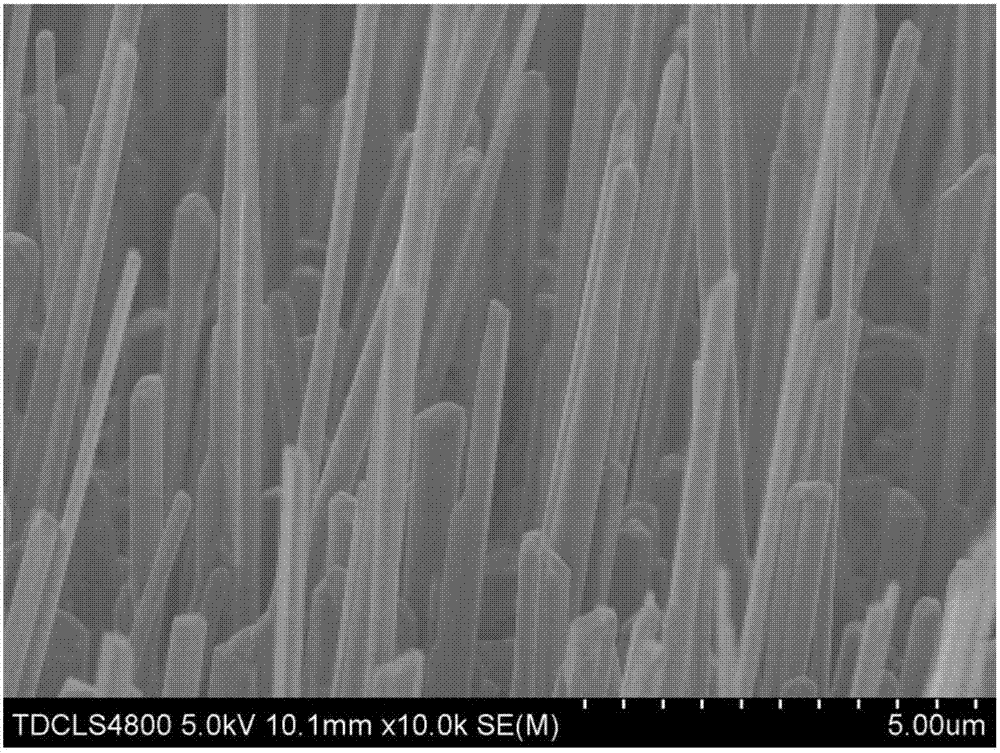

[0027] Soak the surface of the pure copper mesh with hydrochloric acid or ethanol and ultrasonically clean it with deionized water, dry it for later use; place the pure copper mesh in a ceramic ark and heat it in a box-type electric furnace at a heating temperature of 500°C for 5 hours. CuO nanorods grown on copper grids were prepared after cooling in the furnace.

[0028] The prepared copper mesh grown with CuO nanorods was placed in Co(NO 3 ) 2 , NH 4 F, potassium sodium tartrate (C 4 h 4 QUR 6 -4H 2 O) and urea (CO(NH 2 ) 2 ) in the mixed solution of water and ethylene glycol, carry out hydrothermal reaction in the reactor. Among them, water, ethylene glycol, Co(NO 3 ) 2, NH 4 F, potassium sodium tartrate (C 4 h 4 QUR 6 -4H 2 O) and urea (CO(NH 2 ) 2 ) is 8.4:2.7:0.3:0.5:0.1:1.3, the filling ratio of the mixed solution to the reactor is 2:1; the heating temperature is 110°C; the heating time is 6h.

[0029] The above reaction product was washed with deioni...

Embodiment 3

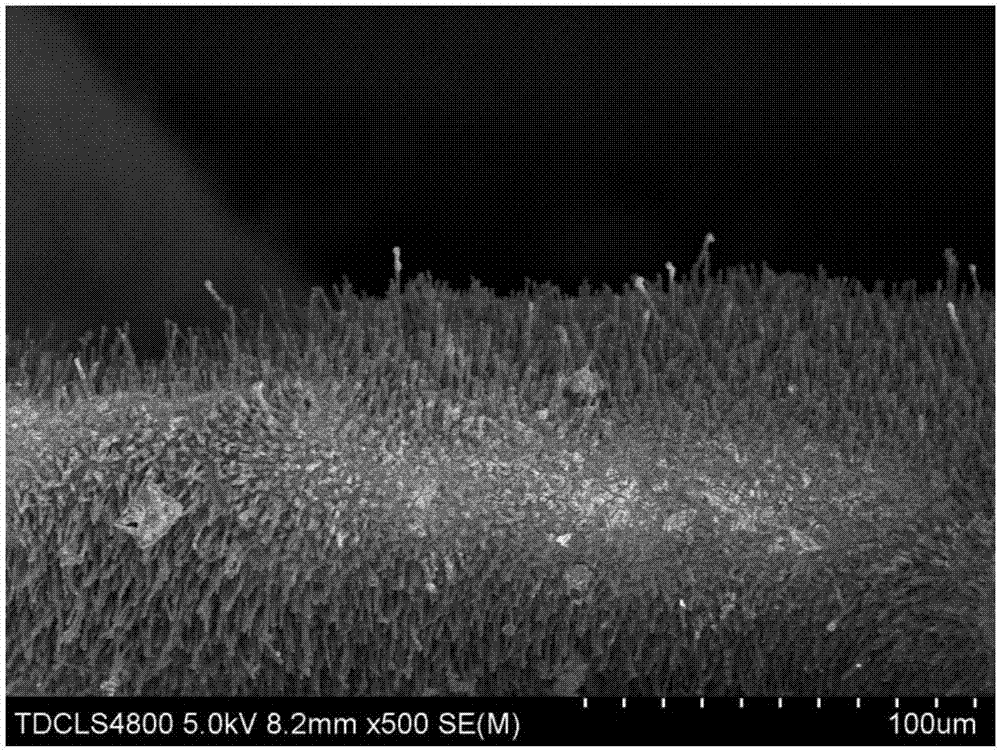

[0031] Soak the surface of the pure copper mesh with hydrochloric acid or ethanol and ultrasonically clean it with deionized water, dry it for later use; place the pure copper mesh in a ceramic ark and heat it in a box-type electric furnace at a heating temperature of 500°C for 5 hours. CuO nanorods grown on copper grids were prepared after cooling in the furnace.

[0032] The prepared copper mesh grown with CuO nanorods was placed in Co(NO 3 ) 2 , NH 4 F, potassium sodium tartrate (C 4 h 4 QUR 6 -4H 2 O) and urea (CO(NH 2 ) 2 ) in the mixed solution of water and ethylene glycol, carry out hydrothermal reaction in the reactor. Among them, water, ethylene glycol, Co(NO 3 ) 2 , NH 4 F, potassium sodium tartrate (C 4 h 4 QUR 6 -4H 2 O) and urea (CO(NH 2 ) 2 ) is 8.4:2.7:0.4:0.5:0.3:1.4, the filling ratio of the mixed solution to the reactor is 2:1; the heating temperature is 100°C; the heating time is 5h.

[0033] The above reaction product was washed with deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com