Composite advanced sewage treatment method

A technology for advanced treatment and sewage, applied in the field of water treatment, can solve problems such as foul smell, lack of oxygen, endangering the ecological environment, etc., and achieve the effects of strong adsorption of positive charges, good purification effect, and good water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

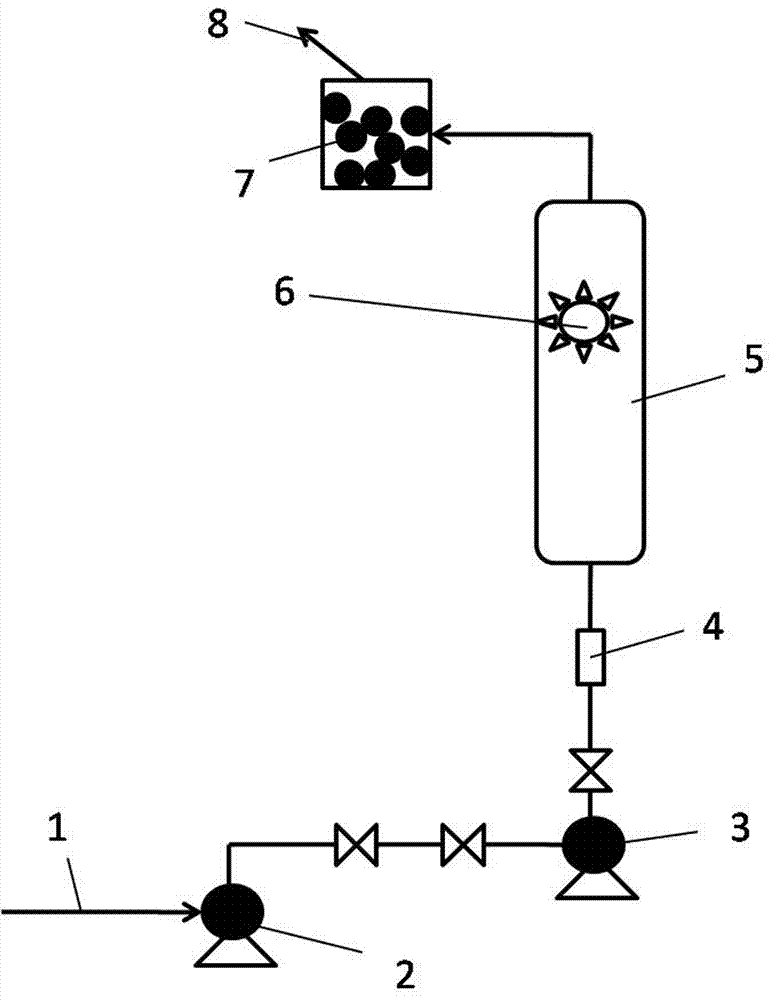

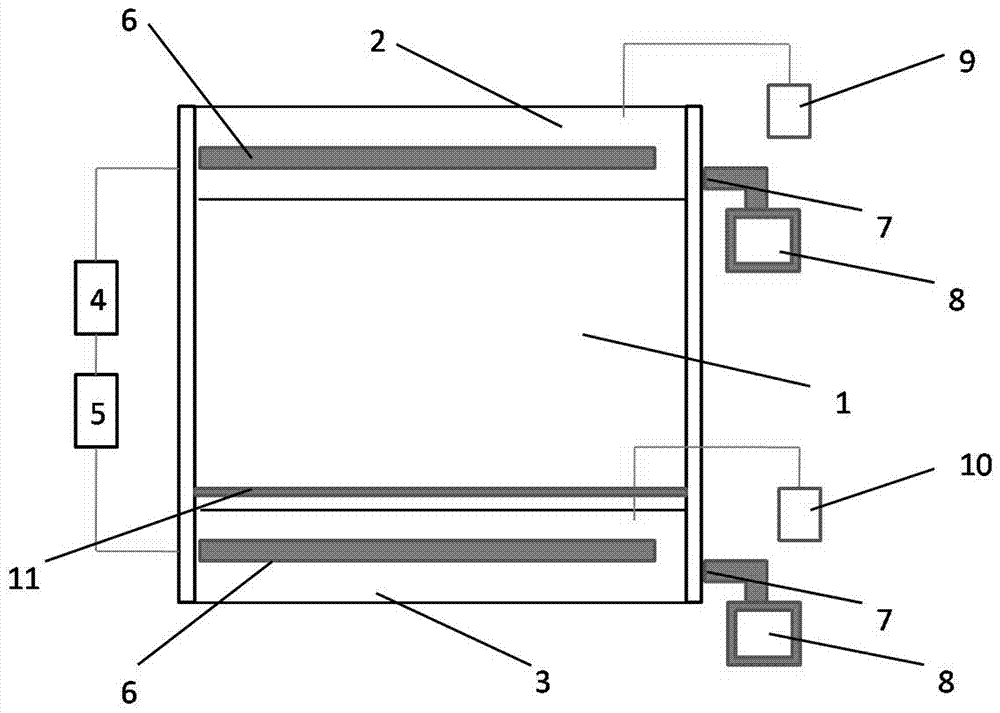

Method used

Image

Examples

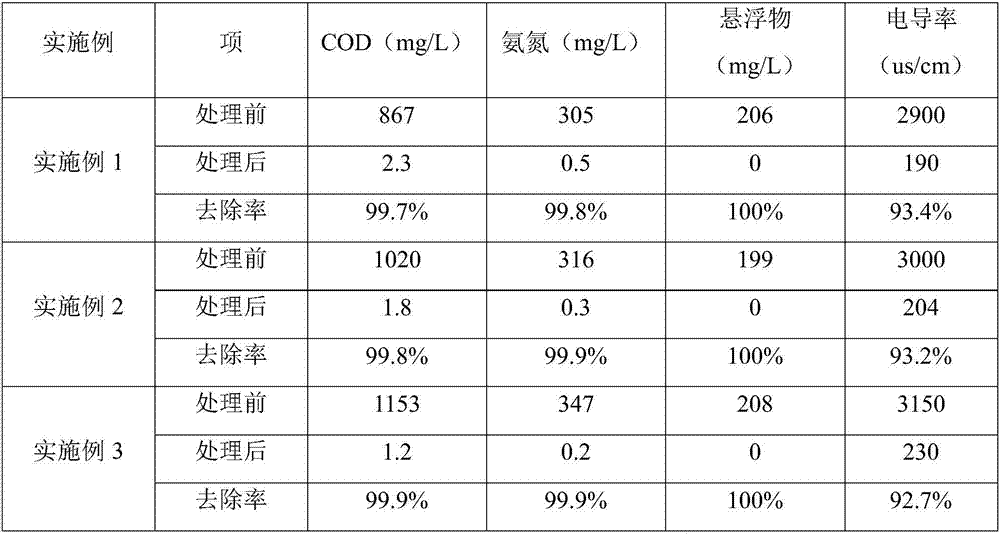

Embodiment 1

[0029] A kind of advanced treatment method of composite sewage, the method comprises the following steps:

[0030]Step 1. Flocculation and sedimentation: the composite sewage is treated by anaerobic expanded granular sludge bed (EGSB)-aerobic membrane bioreactor (MBR) combined process, the influent water volume is 500L / h, water quality: COD 867mg / L , ammonia nitrogen 305mg / L, suspended matter 206mg / L, conductivity 2900us / cm, heavy metal arsenic 2.4mg / L, cadmium 0.1mg / L, chromium 3mg / L, lead 1.2mg / L, mercury 0.13mg / L, copper 27mg / L, manganese 15mg / L, pass into the flocculation sedimentation tank, put 0.3kg flocculant in per ton of sewage at the water inlet, this flocculant comprises each component of following parts by weight: polyferric sulfate 8 parts, bentonite 10 parts, 5 parts of diatomite, 15 parts of chitosan, 2000 parts of deionized water, after clarification, put one or more of NaOH solid, soda ash solid, quicklime for chemical precipitation;

[0031] Step 2. Media f...

Embodiment 2

[0037] A method for advanced treatment of composite sewage, the method comprising the following steps:

[0038] Step 1. Flocculation and sedimentation: the composite sewage is treated by anaerobic expanded granular sludge bed (EGSB)-aerobic membrane bioreactor (MBR) combined process, the influent water volume is 500L / h, and the water quality: COD 1020mg / L , ammonia nitrogen 316mg / L, suspended matter 199mg / L, conductivity 3000us / cm, heavy metal arsenic 1.3mg / L, cadmium 1.0mg / L, chromium 1.8mg / L, lead 0.9mg / L, mercury 0.2mg / L, copper 34mg / L, manganese 6mg / L, pass into the flocculation sedimentation tank, put 0.3kg flocculant per ton of sewage at the water inlet, the flocculant includes the following components in parts by weight: 15 parts of polyferric sulfate, 15 parts of bentonite , 7 parts of diatomite, 23 parts of chitosan, 2500 parts of deionized water, after clarification, put one or more of NaOH solid, soda ash solid, quicklime for chemical precipitation;

[0039] Step 2...

Embodiment 3

[0045] A method for advanced treatment of composite sewage, the method comprising the following steps:

[0046] Step 1. Flocculation and sedimentation: the composite sewage is treated by anaerobic expanded granular sludge bed (EGSB)-aerobic membrane bioreactor (MBR) combined process, the influent water volume is 500L / h, water quality: COD 1153mg / L , ammonia nitrogen 347mg / L, suspended matter 208mg / L, conductivity 3150us / cm, heavy metal arsenic 4.7mg / L, cadmium 0.5mg / L, chromium 4.4mg / L, lead 1.0mg / L, mercury 0.19mg / L, copper 22mg / L, manganese 7mg / L, pass into the flocculation sedimentation tank, put 0.3kg flocculant per ton of sewage at the water inlet, the flocculant includes the following components in parts by weight: 15 parts of polyferric sulfate, 15 parts of bentonite , 7 parts of diatomite, 23 parts of chitosan, 2500 parts of deionized water, after clarification, put one or more of NaOH solid, soda ash solid, quicklime for chemical precipitation;

[0047] Step 2. Media...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com