Preparation method of calcium phosphate-coated magnesium powder

A technology of calcium hydrogen phosphate package and magnesium powder, which is applied in transportation and packaging, liquid chemical plating, metal processing equipment, etc., can solve the problems of fast degradation of magnesium and magnesium alloys, structural failure, implantation failure, etc., and achieve structural Small and uniform, performance-enhancing, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

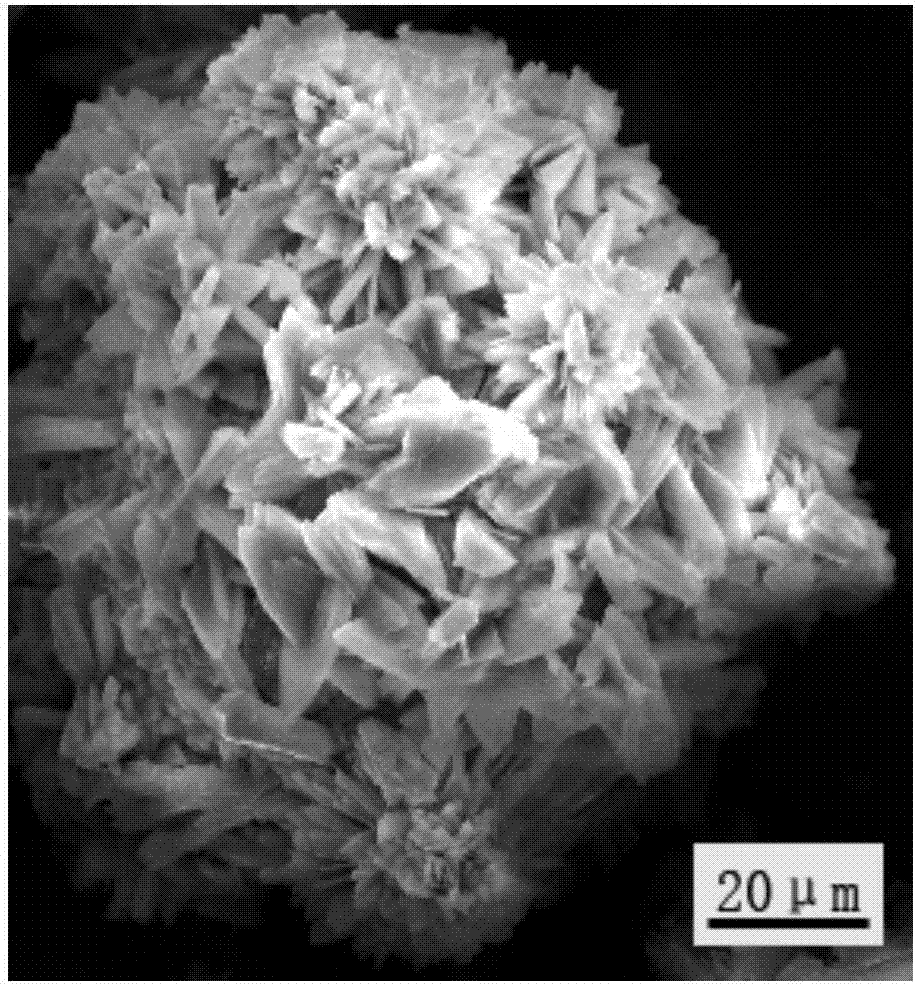

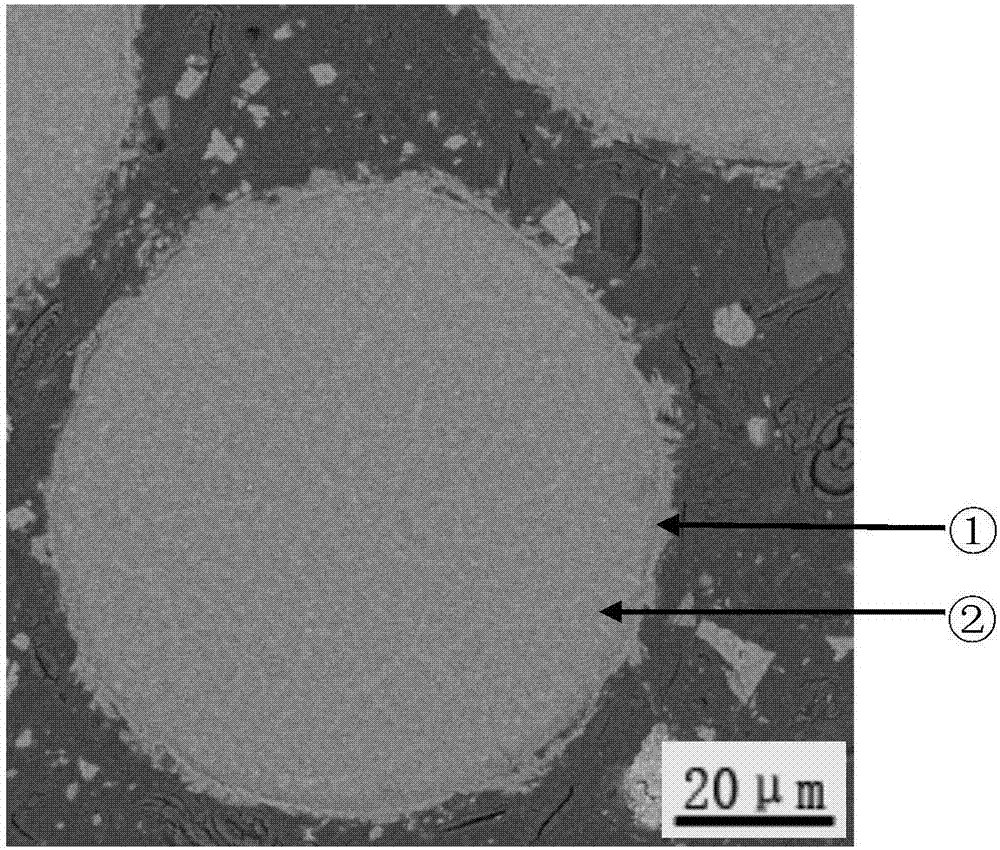

[0026] Prepare 0.01mol / L Ca(NO 3 ) 2 and KH 2 PO 4 100ml each solution, in Ca(NO 3 ) 2 Add 2 g complexing agent C to the solution 10 h 14 N 2 Na 2 o 8 • 2H 2 0, after it is fully dissolved, under the stirring of a magnetic stirrer (400 r / min), the KH 2 PO 4 Slowly add Ca(NO 3 ) 2 solution until uniformly mixed, and finally adjust the pH value to 3.6 with 1mol / L sodium hydroxide solution, and adjust the solution temperature to 10°C. Weigh 2 g of magnesium powder and slowly add it to the above solution, use a stirring speed of 400r / min to disperse the powder evenly in the solution, then reduce the stirring speed to 200r / min, the reaction ends after 30min, take out the powder and carry out centrifugal drying Drying in a drying oven to prepare magnesium powder coated with calcium hydrogen phosphate dihydrate.

Embodiment 2

[0028] Prepare 0.01mol / L Ca(NO 3 ) 2 and KH 2 PO 4 100ml each solution, in Ca(NO 3 ) 2 Add 2g complexing agent C to the solution 10 h 14 N 2 Na 2 o 8 • 2H 2 0. After it is fully dissolved, stir the KH with a magnetic stirrer (300 r / min). 2 PO 4 Slowly add Ca(NO 3 ) 2 solution until uniformly mixed, and finally adjust the pH value to 4.2 with 1mol / L sodium hydroxide solution, and adjust the solution temperature to 15°C. Weigh 2 g of magnesium powder and slowly add it to the above solution. Use a stirring speed of 300 r / min to disperse the powder evenly in the solution, then reduce the stirring speed to 200 r / min. After 25 minutes, the reaction is over, and the powder is taken out for centrifugal drying. Finally, it is dried in an oven to obtain magnesium powder coated with calcium hydrogen phosphate dihydrate.

Embodiment 3

[0030] Prepare 0.01mol / L Ca(NO 3 ) 2 and KH 2 PO 4 100ml each solution, in Ca(NO 3 ) 2 Add 2g complexing agent C to the solution 10 h 14 N 2 Na 2 o 8 • 2H 2 O, after it is fully dissolved, under the magnetic stirrer (250 r / min), the KH 2 PO 4 Slowly add Ca(NO 3 ) 2 solution until uniformly mixed, and finally adjust the pH value to 4.8 with 1 mol / L sodium hydroxide solution, and adjust the solution temperature to 20°C. Weigh 2 g of magnesium powder and slowly add it to the above solution, and use a stirring speed of 250 r / min to disperse the powder evenly in the solution and cause a deposition reaction. After 20 minutes, the reaction ends, and the powder is taken out for centrifugal drying and placed in a drying oven. Drying in medium to obtain calcium hydrogen phosphate dihydrate coated magnesium powder powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com