High-concentration compound microbial fertilizer prepared by tower-type melt granulation and preparation method thereof

A technology of complex microbial bacteria and tower melt granulation, which is applied in the direction of urea compound fertilizer, fertilizer mixture, animal carcass fertilizer, etc., can solve the problem of increasing harmful substances in chemical residues, increasing harmful bacteria and harmful substances, affecting human health and Survival and other issues, to achieve the effect of saving labor, high survival rate of probiotics, and excellent control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

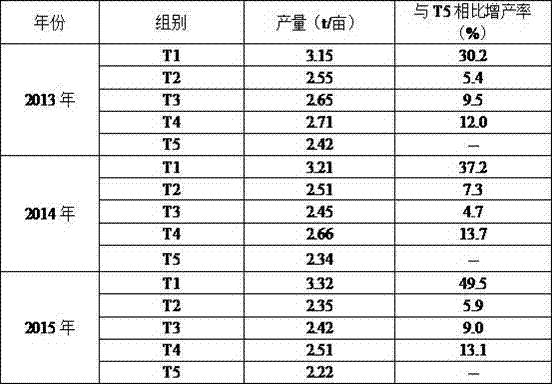

Examples

Embodiment 1

[0023] A tower-type melt granulation high-concentration compound microbial fertilizer, which is made of the following raw materials in parts by weight: 300 parts of urea, 130 parts of monoammonium phosphate, 30 parts of humic acid, 200 parts of potassium sulfate, and 1 10 parts of compound microbial agent, 10 parts of polyaspartic acid, 30 parts of zinc sulfate, 20 parts of superphosphate, 50 parts of oyster powder, 20 parts of silanized modified zeolite, 3 parts of polyvinyl alcohol, 5 parts of urea formaldehyde share.

[0024] The composite microbial bacterial agent is prepared by the following method: after activating Bacillus pumilus, Phanerochaete chrysosporium and Bacillus natto, respectively culture them in a liquid seed medium at 25°C for 15-20 hours, and then Transfer 1% of the inoculum into a sterilized large tank culture medium, culture at 30°C for 25 hours, compound the strains according to the mass ratio of 1:2:1 and freeze-dry to make freeze-dried powder. .

[...

Embodiment 2

[0030] A tower-type melt granulation high-concentration compound microbial fertilizer, which is made of the following raw materials in parts by weight: 500 parts of urea, 250 parts of monoammonium phosphate, 60 parts of humic acid, 300 parts of potassium sulfate, and 10 parts of magnesium sulfate 20 parts of compound microbial agent, 30 parts of polyaspartic acid, 50 parts of zinc sulfate, 30 parts of superphosphate, 100 parts of oyster powder, 40 parts of silanized modified zeolite, 5 parts of polyvinyl alcohol, 8 parts of urea formaldehyde share.

[0031] The composite microbial bacterial agent is prepared by the following method: after activating Bacillus pumilus, Phanerochaete chrysosporium and Bacillus natto, respectively culture them in a liquid seed medium at 25°C for 15-20 hours, and then Transfer 1% of the inoculum into a sterilized large tank culture medium, culture at 30°C for 25 hours, compound the strains according to the mass ratio of 1:2:1 and freeze-dry to make...

Embodiment 3

[0035] A tower-type melt granulation high-concentration compound microbial fertilizer, which is made of the following raw materials in parts by weight: 400 parts of urea, 180 parts of monoammonium phosphate, 50 parts of humic acid, 250 parts of potassium sulfate, and 5 parts of magnesium sulfate 15 parts of compound microbial agent, 20 parts of polyaspartic acid, 40 parts of zinc sulfate, 25 parts of superphosphate, 80 parts of oyster powder, 30 parts of silanized modified zeolite, 4 parts of polyvinyl alcohol, 6 parts of urea formaldehyde share.

[0036]The composite microbial bacterial agent is prepared by the following method: after activating Bacillus pumilus, Phanerochaete chrysosporium and Bacillus natto, respectively culture them in a liquid seed medium at 25°C for 15-20 hours, and then Transfer 1% of the inoculum into a sterilized large tank culture medium, culture at 30°C for 25 hours, compound the strains according to the mass ratio of 1:2:1 and freeze-dry to make fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com