A method for removing wax before electroplating steel parts for pumps

A technology for steel and pumps, applied in the field of pump manufacturing, can solve the problems of incomplete cleaning, high cost, environmental hazards, etc., and achieve the effect of speeding up wax removal, inhibiting the formation of foam, and safe wax removal process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

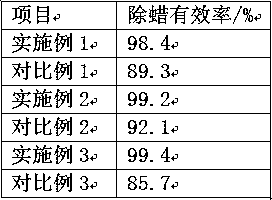

Examples

Embodiment 1

[0014] A method for removing wax before electroplating steel parts for pumps, comprising the following steps: 3 pieces of steel parts are connected in parallel and put into a phosphorus-free cleaning solution as cathodes, connected with direct current, and electrolytically remove wax, wherein the phosphorus-free cleaning solution consists of the following Made from components in parts by weight: 29 parts of sodium acetate, 5 parts of castor oil, 1 part of trisodium isocitrate, 2 parts of behenic acid amide, 8 parts of laurylamine, 6 parts of dipotassium glycyrrhizinate, 300 parts of water .

[0015] Specifically, the voltage during electrolysis is 24V, the current is 2A, and the power-on time is 50s.

[0016] Specifically, the phosphorus-free cleaning solution is prepared by the following method: after mixing behenic acid amide and laurylamine, grinding it into 200 mesh, adding it to water, stirring at a speed of 400r / min for 5 minutes, adding sodium acetate and castor oil to ...

Embodiment 2

[0019] A method for removing wax before electroplating steel parts for pumps, comprising the following steps: 4 pieces of steel parts are connected in parallel and put into a phosphorus-free cleaning solution as cathodes, and connected to a direct current to perform electrolytic wax removal, wherein the phosphorus-free cleaning solution consists of the following Made from components in parts by weight: 31 parts of sodium acetate, 6 parts of castor oil, 2 parts of trisodium isocitrate, 3 parts of behenamide, 9 parts of laurylamine, 7 parts of dipotassium glycyrrhizinate, 310 parts of water .

[0020] Specifically, the voltage during electrolysis is 24V, the current is 2A, and the power-on time is 60s.

[0021] Specifically, the phosphorus-free cleaning solution is prepared by the following method: after mixing behenic acid amide and laurylamine, grinding it into 200 mesh, adding it to water, stirring at a speed of 400r / min for 5 minutes, adding sodium acetate and castor oil to ...

Embodiment 3

[0024] A method for removing wax before electroplating iron and steel parts for pumps, comprising the following steps: put five steel parts in parallel as cathodes into a phosphorus-free cleaning solution, connect direct current, and perform electrolytic wax removal, wherein the phosphorus-free cleaning solution consists of the following Made from components in parts by weight: 33 parts of sodium acetate, 7 parts of castor oil, 3 parts of trisodium isocitric acid, 4 parts of behenamide, 10 parts of laurylamine, 8 parts of dipotassium glycyrrhizinate, 320 parts of water .

[0025] Specifically, the voltage during electrolysis is 24V, the current is 2A, and the power-on time is 70s.

[0026] Specifically, the phosphorus-free cleaning solution is prepared by the following method: after mixing behenic acid amide and laurylamine, grinding it into 200 mesh, adding it to water, stirring at a speed of 400r / min for 5 minutes, adding sodium acetate and castor oil to it , isocitric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com