Load type fluorine removal agent and preparation method thereof

A defluorinating agent and supported technology, applied in the field of supported defluorinating agent and its preparation, can solve the problems of low adsorption capacity of defluorinating adsorbent, inability to be directly industrialized application, elapse, etc., and achieve good adsorption effect and defluorination efficiency. High, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

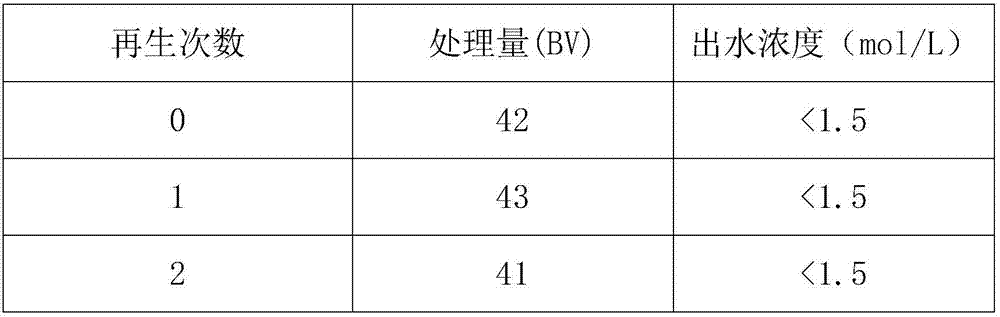

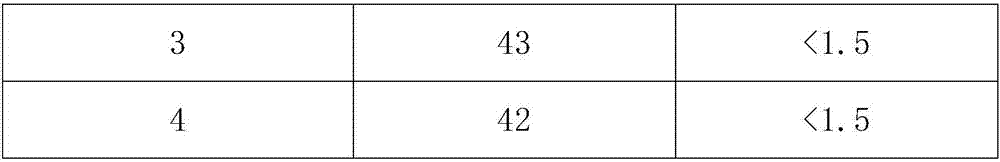

Examples

Embodiment 1

[0028] A kind of loading type defluorination agent of this embodiment comprises yellow sand, and the inorganic defluorination agent deposited on the surface of yellow sand, the mass ratio of inorganic defluorination agent and yellow sand is 4:1, and inorganic defluorination agent has layered Crystal structure.

[0029] A kind of preparation method of above-mentioned supported type defluorinating agent, comprises the following steps:

[0030] Step 1) Solution preparation:

[0031] Prepare a 0.4mol / L saline solution and prepare a 2mol / L sodium hydroxide aqueous solution; wherein the saline solution is specifically an aqueous solution of magnesium chloride and aluminum chloride;

[0032] Step 2) yellow sand pretreatment:

[0033] Pass the raw material yellow sand through a 60-mesh sieve, take the yellow sand under the sieve, wash and dry it with deionized water;

[0034] Step 3) Response:

[0035] Add deionized water in the yellow sand that step 2) obtains, and the mass ratio...

Embodiment 2

[0039] A load-type defluorination agent of this embodiment includes yellow sand, and an inorganic defluorination agent deposited on the surface of the yellow sand. The mass ratio of the inorganic defluorination agent to the yellow sand is 2:1, and the inorganic defluorination agent has a layered Crystal structure.

[0040] A kind of preparation method of above-mentioned supported type defluorinating agent, comprises the following steps:

[0041] Step 1) Solution preparation:

[0042] Prepare a 1.5mol / L saline solution and prepare a 3mol / L sodium hydroxide aqueous solution; wherein the saline solution is specifically an aqueous solution of nickel nitrate and aluminum nitrate;

[0043] Step 2) yellow sand pretreatment:

[0044] Pass the raw material yellow sand through a 80-mesh sieve, take the yellow sand under the sieve, wash and dry it with deionized water;

[0045] Step 3) Response:

[0046] Add deionized water in the yellow sand that step 2) obtains, and the mass ratio ...

Embodiment 3

[0050] A load-type defluorination agent of this embodiment includes yellow sand, and an inorganic defluorination agent deposited on the surface of the yellow sand. The mass ratio of the inorganic defluorination agent to the yellow sand is 1:1, and the inorganic defluorination agent has a layered Crystal structure.

[0051] A kind of preparation method of above-mentioned supported type defluorinating agent, comprises the following steps:

[0052] Step 1) Solution preparation:

[0053] Prepare a 1mol / L saline solution, and prepare a 2mol / L aqueous solution of a mixture of sodium hydroxide and sodium carbonate; wherein the saline solution is specifically an aqueous solution of magnesium chloride and ferric chloride;

[0054] Step 2) yellow sand pretreatment:

[0055] Pass the raw material yellow sand through a 80-mesh sieve, take the yellow sand under the sieve, wash and dry it with deionized water;

[0056] Step 3) Response:

[0057]Add deionized water in the yellow sand tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com