Preparation method and application of biomass graphitized porous carbon material

A technology for porous carbon materials and biomass materials, which is applied in the field of preparation of biomass graphitized porous carbon materials, can solve problems such as damage and corrosive environment of production equipment, and achieve the effects of low cost, shortened production cycle and abundant sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take some fresh bamboo poles, chop them up, wash them, dry them, and then transfer them to a tube furnace for carbonization at 400°C for 2 hours under the protection of argon to obtain carbonized bamboo materials; 0.60g of carbonized materials, 0.99 g potassium ferrate (K 2 FeO 4 ) and 45ml of water were uniformly mixed, and then dried; the above mixture was transferred to a tube furnace for heat treatment, and kept at 800°C for 2 hours under the protection of argon; Substance graphitized porous carbon material.

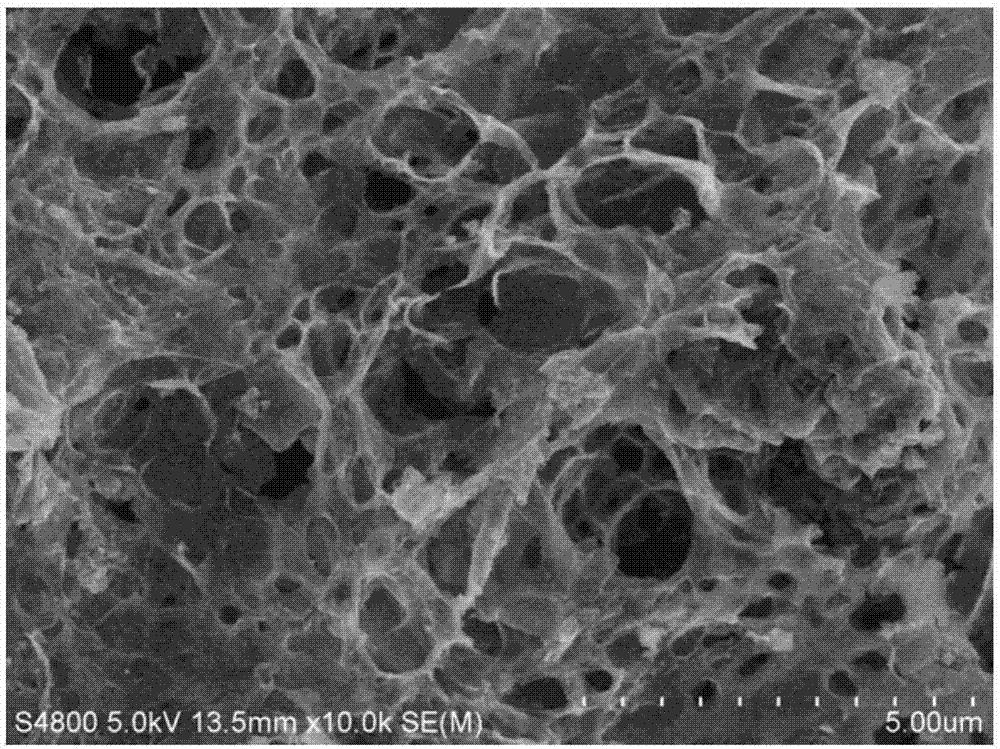

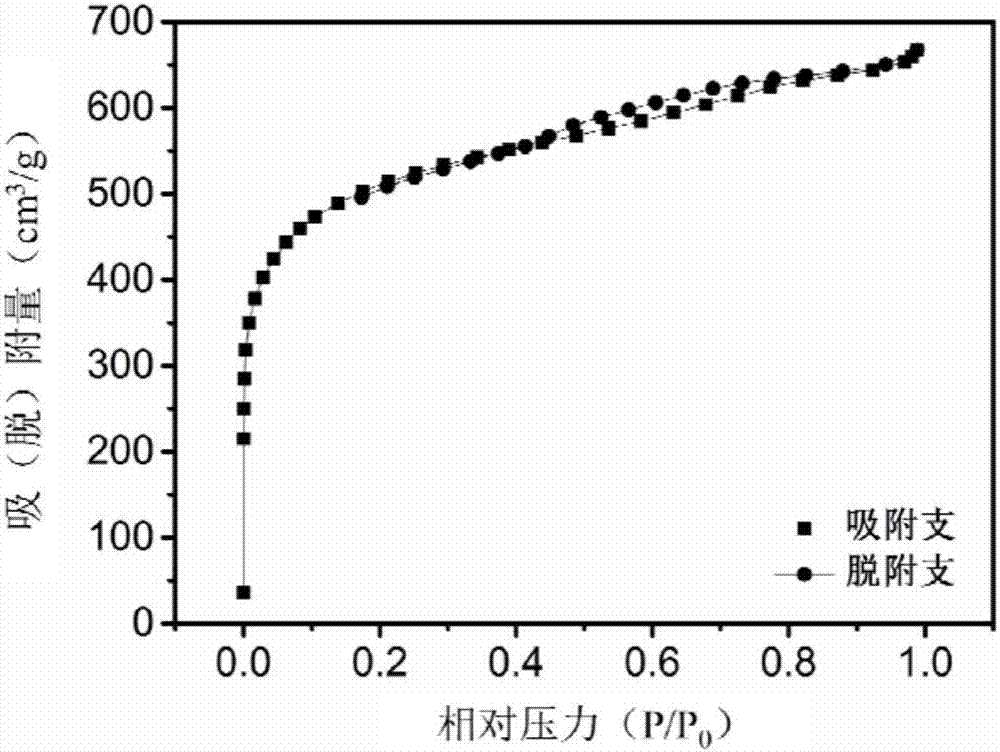

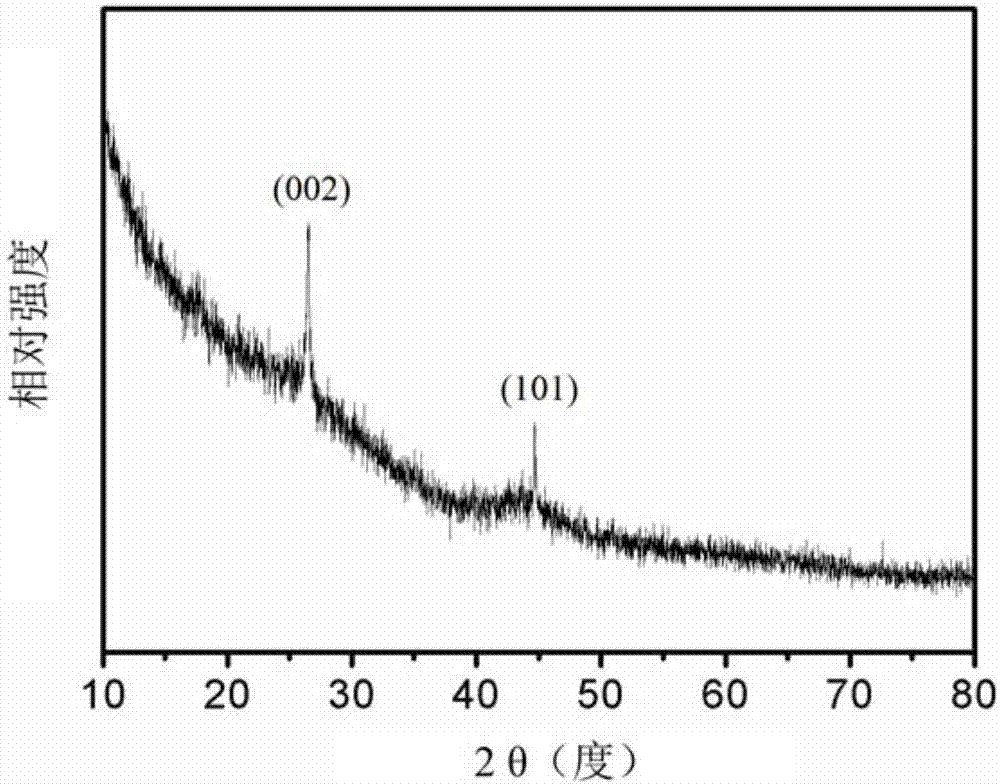

[0036] The above biomass graphitized porous carbon material was observed by scanning electron microscope (SEM), and its morphology is as follows: figure 1 shown. Depend on figure 1 It can be seen that the prepared biomass graphitized porous carbon material has an obvious three-dimensional porous structure. Specific surface area test is carried out to described biomass graphitized porous carbon material, obtain the N of this material 2 Adsorption-desorpti...

Embodiment 2

[0038] Take some fresh bamboo poles, chop them up, wash them, dry them, and transfer them to a tube furnace for carbonization at 500°C for 1 hour under the protection of argon to obtain carbonized bamboo materials; 0.60 g of carbonized materials, 0.99 g potassium ferrate (K 2 FeO 4 ) and 45ml of water were uniformly mixed, and then dried; the above mixture was transferred to a tube furnace for heat treatment, and kept at 1000°C for 1 hour under the protection of argon; Substance graphitized porous carbon material.

[0039] Weigh the biomass graphitized porous carbon material, acetylene black and polyvinylidene fluoride (PVDF) with a mass ratio of 8:1:1, transfer it to a mortar, add a small amount of N-methylpyrrolidone (N -Methylpyrrolidone, NMP) as a solvent, fully ground to a paste, and the mixture was coated on a nickel foam sheet with a size of 2 mm * 1 mm, then vacuum-dried at 120°C for 12 hours, and finally pressed at a pressure of 10Mpa for 1 Minutes to get supercapa...

Embodiment 3

[0042] Take the discarded corn stalks, chop them up, wash them, dry them, and transfer them to a tube furnace for carbonization at 400°C for 4 hours under the protection of nitrogen to obtain carbonized materials of corn stalks; 0.60 g of carbonized materials, 6.0 g potassium ferrate (K 2 FeO 4 ) and 50ml of water were uniformly mixed, and then dried; the above mixture was transferred to a tube furnace for heat treatment, and kept at 1500°C for 6 hours under the protection of argon; Substance graphitized porous carbon material. The carbon electrode prepared from the biomass graphitized porous carbon material obtained in this example was selected as the working electrode, and a constant current charge and discharge test was performed to calculate the capacitance at different current densities. The electrode had a capacitance of 163.2 F / g at a current density of 0.5 A / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com