Total nutrition carbon-based soil remediation fertilizer and production method thereof

A technology of soil remediation and production methods, applied in the direction of organic fertilizers, inorganic fertilizers, nitrate fertilizers, etc., can solve problems such as carbon and nitrogen imbalances, nutritional imbalances, etc., and achieve the effects of improving compaction, reducing labor, and improving the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

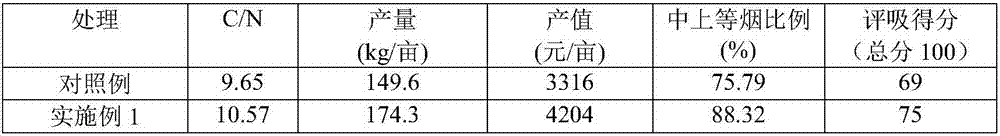

Embodiment 1

[0038] 1. The process of preparing peanut shell biochar is as follows:

[0039] (1) Air-dry the peanut shells, then crush them to 2mm, and put them into the continuous carbonization equipment through the auger equipment.

[0040] (2) soak the pulverized material obtained in step 1 in diamine hydrogen phosphate modifier with a concentration of 1%, and then dry it in a drum air dryer, and control the moisture at 15%.

[0041](3) Put the peanut shells treated in step 2 into the continuous biomass carbonization equipment. The material is pre-oxidized at 160°C in the upper area of the equipment, and the water is volatilized, and then enters the middle area of the equipment at a temperature of 300°C. Primary carbonization under oxygen conditions for 3 minutes; finally, further carbonization at 350°C for 10 minutes in the lower area of the equipment. The carbonized material is continuously output in the auger equipment, and the atomized stabilizer is sprayed at the discharge p...

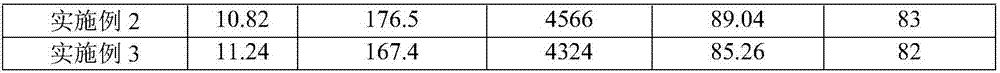

Embodiment 2

[0051] 1. The process of preparing peanut shell biochar is as follows:

[0052] (1) Air-dry the peanut shells, then crush them to 3.5mm, and put them into the continuous carbonization equipment through the auger equipment.

[0053] (2) soak the pulverized material obtained in step 1 in a modifier with a concentration of 5%, and then dry it in a rotary drum air dryer, and control the moisture content at 17.5%.

[0054] (3) Put the peanut shells treated in step 2 into the continuous biomass carbonization equipment. The material is pre-oxidized and volatilized at 185°C in the upper area of the equipment, and then enters the middle area of the equipment at a temperature of 330°C in anaerobic or oxygen-free Primary carbonization under the conditions for 10 minutes; finally, further carbonization in the lower area of the equipment at 385°C for 12 minutes. The carbonized material is continuously output in the auger equipment, and the atomized stabilizer is sprayed at the outle...

Embodiment 3

[0064] 1. The process of preparing peanut shell biochar is as follows:

[0065] (1) Air-dry the peanut shells, then crush them to 5mm, and put them into the continuous carbonization equipment through the auger equipment.

[0066] (2) Soak the pulverized material obtained in step 1 in diamine hydrogen phosphate modifier with a concentration of 10%, and then dry it in a drum air dryer, and control the moisture at 20%.

[0067] (3) Put the peanut shells treated in step 2 into the continuous biomass carbonization equipment. The material is pre-oxidized at 200°C in the upper area of the equipment, and the water is volatilized, and then enters the middle area of the equipment at a temperature of 350°C. Primary carbonization under oxygen conditions for 15 minutes; finally, further carbonization at 400°C for 15 minutes in the lower area of the equipment. The carbonized material is continuously output in the auger equipment, and the atomized stabilizer is sprayed at the discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com