Method for preparing acetovanillone and acetosyringone by catalytically saponifying lignin

A technology of acetosyringone and vanilla ethyl ketone, applied in chemical instruments and methods, preparation of carbon-based compounds, preparation of organic compounds, etc., can solve the problems of underutilization, transformation, and environmental pollution, and achieve heating time Short, high reaction efficiency, efficient degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Weigh 1 g of lignin and 16 mL of isopropanol and mix them into a reaction tank, put the reaction tank into a microwave reactor, set the microwave power to 600 W, and react for 30 min at a certain reaction temperature of 120 °C. After the reaction is complete, take out the digestion tank and let it cool down naturally. The product was filtered and washed with the solvent isopropanol, and the filtered liquid product was uniformly dissolved in isopropanol to 20 mL, and the liquid product was to be detected.

Embodiment 2

[0029] a. Weigh 2.47 g Co(NO 3 ) 2 ·6H 2 O was placed in a beaker, fully diluted with deionized water to form a solution, and an equal volume was impregnated in 10 g Al 2 o 3 support, stirred and impregnated at room temperature for 24 h. Then put into the drying box 85 ° C drying for 12 h to obtain the catalyst precursor, in the air atmosphere, the catalyst precursor was carried out in the muffle furnace for 500 ° C, calcination for 4 h. Finally, the calcined catalyst was heated in 90 mL / min of H 2 Reduction under the atmosphere for 1.5 h, the reduction temperature is 550 ° C, the catalyst 5% Co / Al can be obtained 2 o 3 .

[0030] b. Weigh 1 g of lignin, 16 mL of isopropanol, mix them into the reaction tank, and add 0.5 g of catalyst 5%Co / Al 2 o 3 Mix together in a reaction tank, put the reaction tank into a microwave reactor, set the microwave power to 600 W, and react for 30 min at a certain reaction temperature of 120 °C. After the reaction is complete, take o...

Embodiment 3~5

[0032] a. 5% Co / ZrO 2 , 5% Co / CeO 2 , 5% Co / MgO catalyst preparation process adopts a step in embodiment 2, and difference is to use different carrier ZrO respectively 2 , CeO 2 and MgO to prepare the catalyst.

[0033] b. The degradation step of lignin and catalyst in isopropanol solvent adopts the b step in Example 2, the difference is that the catalyst type added is respectively 5% Co / ZrO 2 , 5% Co / CeO 2 , 5% Co / MgO.

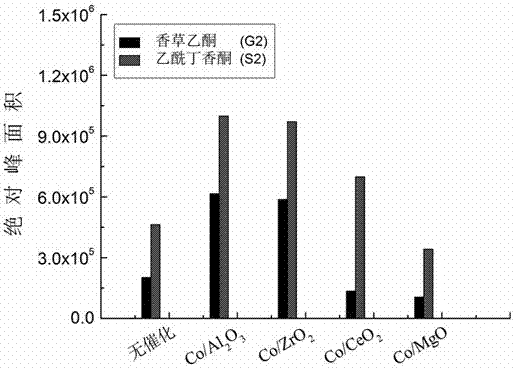

[0034] The liquid product was qualitatively detected by GC / MS, and the relationship between the peak areas of two high-yield products (vanillyl ethyl ketone and acetosyringone) in the liquid product was directly obtained. The effect of different catalysts on the distribution of lignin alcoholysis products is shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com