2-aminobenzimidazole sterilization microsphere, and synthetic method and application thereof

A technology of ‐aminobenzimidazole and synthesis method, applied in the field of 2‐aminobenzimidazole bactericidal microspheres and its synthesis, can solve the problem of bacterial scale, slime stripping and poor washing effect, high transportation and storage costs, and toxic by-products etc. to achieve the effects of easy mass production and automatic control, high physical stability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

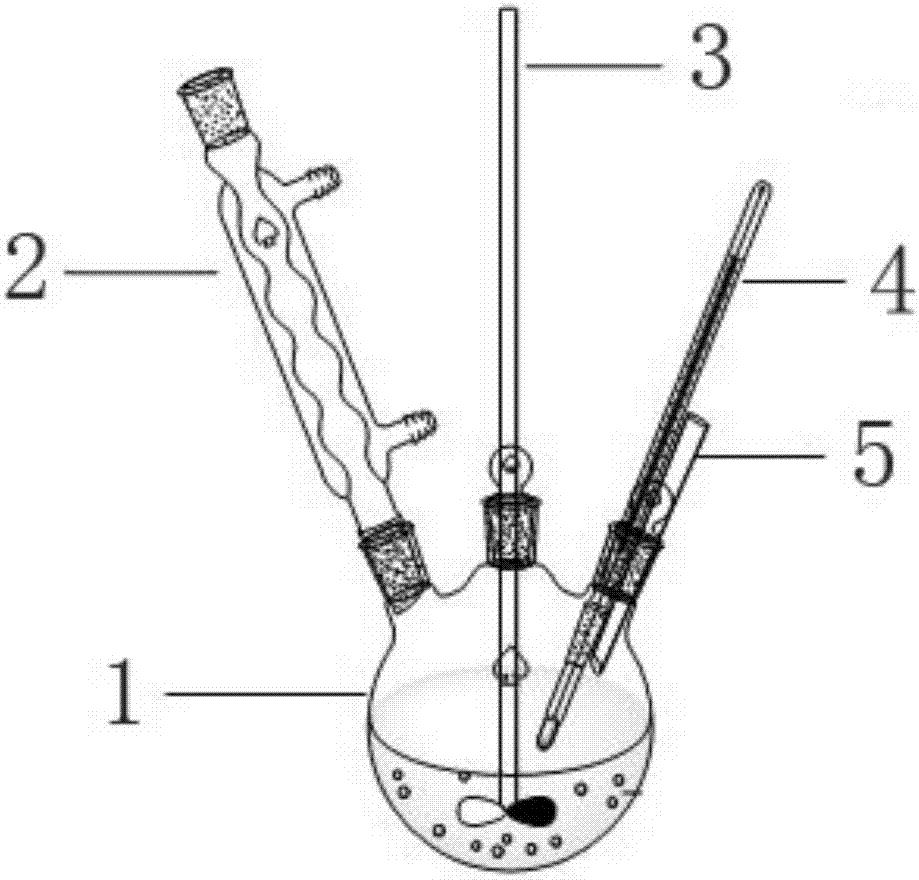

[0031] Measure 40 mL of reaction solvent into a three-necked flask with a volume of 100 mL, and add 60.0 mg of precursor (chlorine balls) to soak overnight. After the parent body is fully swollen, add 2-aminobenzimidazole with a molar ratio of 1:3 to 5 and catalyst metal sodium accounting for 3 to 7% of the added amount of the parent body into the three-necked flask. The reaction was stirred at 70° C. to 90° C., and nitrogen was protected throughout the reaction. After reacting for 10-12 hours, filter out the microspheres in the three-necked flask, then soak and wash them with the reaction solvent until the washing liquid is colorless or there is no obvious attachment on the surface of the microspheres, wash with distilled water, then soak with NaOH aqueous solution, wash with water, and then After repeated washing several times with absolute ethanol, acetone, and ether in sequence, the filtered microspheres were vacuum-dried at 50°C for later use.

[0032] Quaternization of ...

Embodiment 2

[0037] The synthetic method of the 2-aminobenzimidazole bactericidal microsphere of the present embodiment, comprises the following steps:

[0038] (1) Using chlorine balls as the matrix, soak the chlorine balls in the solvent toluene to make them fully swell, add 2-aminobenzimidazole as the ligand, the molar ratio of the matrix to the ligand is 1:4, and add catalyst sodium metal , the amount added is 5% of the amount added to the matrix; under the protection of nitrogen, stir the reaction at 80°C at a speed of 200rpm for 11 hours, first soak and wash with the reaction solvent toluene until the washing liquid is colorless or there is no obvious attachment on the surface of the microspheres, then wash with distilled water After that, soak in NaOH aqueous solution, wash with water, and then wash repeatedly with absolute ethanol, acetone, and ether for 3 to 5 times. After washing, vacuum dry at 50°C for later use;

[0039] (2) Place the product obtained in step (1) in a reaction...

Embodiment 3

[0052] The synthetic method of the 2-aminobenzimidazole bactericidal microsphere of the present embodiment, comprises the following steps:

[0053] (1) Taking chlorine balls as the matrix, soaking the chlorine balls in a solvent to make them fully swell, adding 2‐aminobenzimidazole as a ligand, the molar ratio of the matrix to the ligand is 1:3, adding catalyst metal sodium, The addition amount is 3% of the addition amount of the matrix; under the protection of nitrogen, stir and react at 70°C at a speed of 200rpm for 12 hours, first soak and wash with the reaction solvent until the washing liquid is colorless or there is no obvious attachment on the surface of the microspheres, after washing with distilled water, Then soak in NaOH aqueous solution, wash with water, and then wash with absolute ethanol, acetone, and ether repeatedly for 3 to 5 times. After washing, vacuum dry at 50°C for later use;

[0054] (2) Place the product obtained in step (1) in a reaction vessel, add p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com