Oil removing agent for produced water of binary combined flooding and preparation method thereof

A binary compound, degreaser technology, applied in chemical instruments and methods, special compound water treatment, water/sewage treatment, etc. and other problems, to achieve the effect of high oil removal efficiency, low addition amount and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Degreaser H 1 and its preparation method

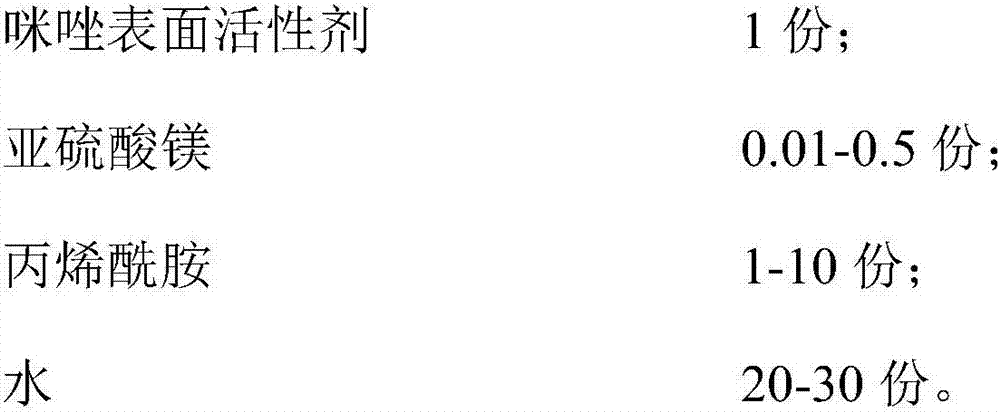

[0029] (1) Degreaser H 1 The composition and its components are as follows:

[0030]

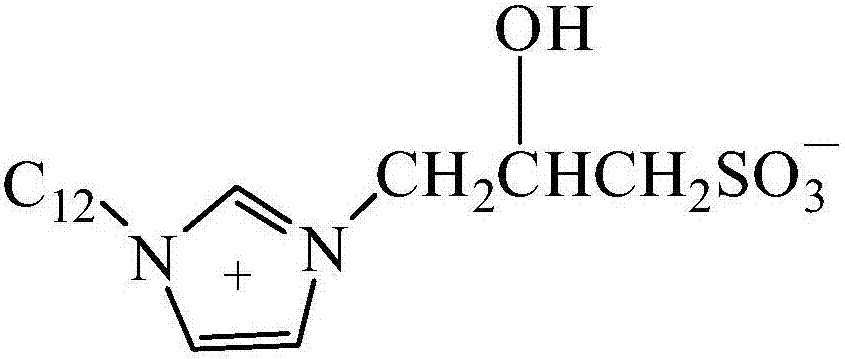

[0031] According to existing literature, the preparation method of described imidazole-based surfactant is as follows:

[0032]

[0033] (2) Degreaser H 1 The preparation method is as follows:

[0034] ①Put 20 parts of water in a beaker in a constant temperature water bath at 50°C, and slowly add 1 part of imidazole-based surfactant at a stirring rate of 200 rpm. After complete addition, continue stirring for 30 minutes to obtain a mixed solution A.

[0035] ② Adjust the temperature of the above constant temperature water bath to 30°C. After constant temperature, add 1 part of acrylamide to the above mixture A at one time, stir at 300rpm, stir for 40min, then raise the temperature to 50°C, stir at 50rpm, constant temperature for 40min, to obtain the mixed solution B.

[0036] ③Reduce the temperature of the above mixe...

Embodiment 2

[0037] Embodiment 2: Degreaser H 2 and its preparation method

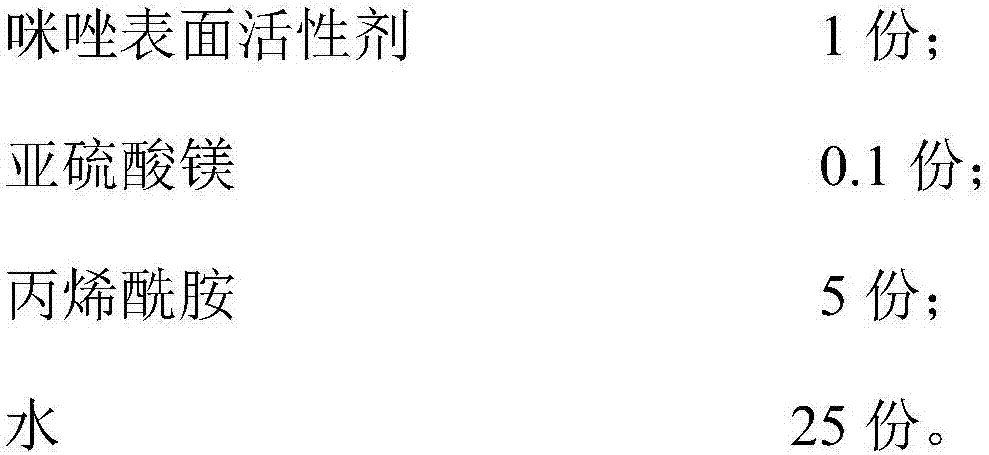

[0038] (1) Degreaser H 2 The composition and its components are as follows:

[0039]

[0040] According to existing literature, the preparation method of described imidazole-based surfactant is as follows:

[0041]

[0042] (2) Degreaser H 2 The preparation method is as follows:

[0043] ①Put 25 parts of water in a beaker in a constant temperature water bath at 60°C, and slowly add 1 part of imidazole-based surfactant at a stirring rate of 350rpm. After complete addition, continue stirring for 45 minutes to obtain a mixed solution A.

[0044] ② Adjust the temperature of the above constant temperature water bath to 32°C. After constant temperature, add 5 parts of acrylamide to the above mixture A at one time, stir at 200rpm, stir for 30min, then raise the temperature to 60°C, and stir at a rate of 100 rpm, constant temperature for 60 minutes, to obtain the mixed solution B.

[0045] ③Reduce the temperat...

Embodiment 3

[0046] Embodiment 3: Degreaser H 3 and its preparation method

[0047] (1) Degreaser H 3 The composition and its components are as follows:

[0048]

[0049] According to existing literature, the preparation method of described imidazole-based surfactant is as follows:

[0050]

[0051] (2) Degreaser H 3 The preparation method is as follows:

[0052] ①Put 30 parts of water in a beaker in a constant temperature water bath at 70°C, slowly add 1 part of imidazole-based surfactant at a stirring rate of 500 rpm, and continue stirring for 60 minutes to obtain a mixed solution A.

[0053]② Adjust the temperature of the above constant temperature water bath to 35°C. After constant temperature, add 10 parts of acrylamide to the above mixture A at one time, stir at 400rpm, stir for 20min, then raise the temperature to 75°C, and stir at 150rpm, constant temperature 80min, to obtain the mixed solution B.

[0054] ③Reduce the temperature of the above mixed liquid B to 35°C. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com