Preparation method of chicoric acid imprinted monolithic column

The technology of monolithic column and cichoric acid is applied in the field of preparation of monolithic column imprinted with cichoric acid, and can solve the problems of complicated process, reduced effect, inability to meet medicinal requirements and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

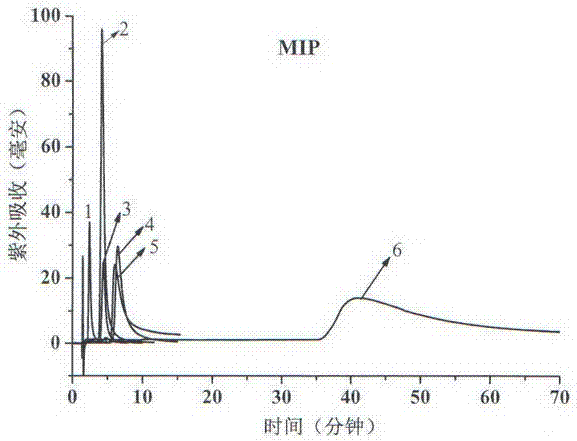

[0018] Preparation of cichoric acid imprinted monolithic column by in situ polymerization:

[0019] a. Dissolve 11.86 mg of cichoric acid and 9.18 mg of metal ion as zinc acetate in 240 μL of N,N-dimethylformamide, 1200 μL of dimethyl sulfoxide and 2468 μL of 1-butyl-3-methylimidazole Tetrafluoroborate, then add 745 μL of ethylene glycol dimethacrylate and 64 μL of 4-vinylpyridine, then add 20 mg of free radical initiator azobisisobutyronitrile, ultrasonic for 10 minutes, remove the dissolved After the solution is completely mixed, transfer the solution to a stainless steel column with a length of 100mm and a diameter of 4.6mm, quickly seal both ends of the stainless steel column, and react in a constant temperature water bath at a temperature of 60°C for 18 hours;

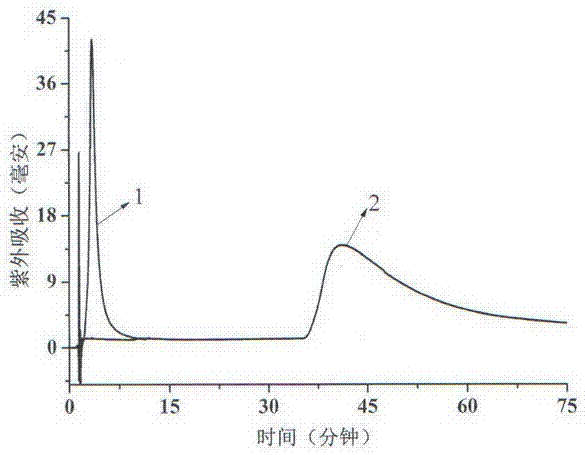

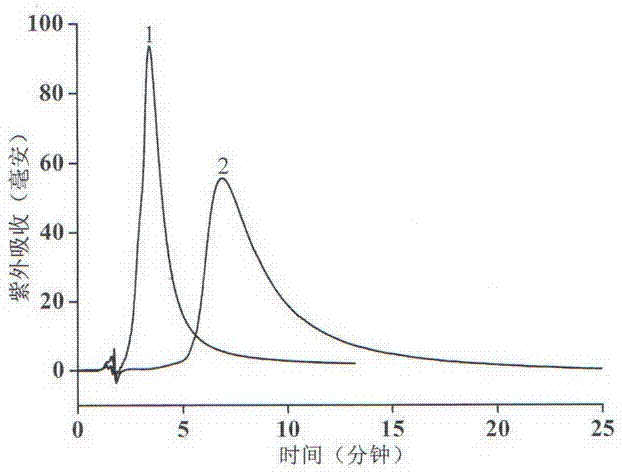

[0020] b. Take the stainless steel column out of the water bath, install the column head, connect it to the high-pressure infusion pump, wash the whole column with a mixture of methanol-acetic acid 150mL with a vo...

Embodiment 2

[0023] Preparation of cichoric acid imprinted monolithic column by in situ polymerization:

[0024] a. Dissolve 11.86 mg of cichoric acid and 9.18 mg of metal ion as zinc acetate in 240 μL of N,N-dimethylformamide, 1200 μL of dimethyl sulfoxide and 2468 μL of 1-butyl-3-methylimidazole Tetrafluoroborate, then add 560 μL of ethylene glycol dimethacrylate and 64 μL of 4-vinylpyridine, then add 20 mg of free radical initiator azobisisobutyronitrile, ultrasonic for 15 minutes, remove the dissolved After the solution is completely mixed, transfer the solution to a stainless steel column with a length of 100mm and a diameter of 4.6mm, quickly seal both ends of the stainless steel column, and react in a constant temperature water bath at a temperature of 60°C for 18 hours;

[0025] b. Take out the stainless steel column from the water bath, install the column head, connect it to the high-pressure infusion pump, wash the whole column with a mixture of methanol-acetic acid 200mL with a ...

Embodiment 3

[0028] Preparation of cichoric acid imprinted monolithic column by in situ polymerization:

[0029] a. Dissolve 11.86 mg of cichoric acid and 9.18 mg of metal ion as zinc acetate in 240 μL of N,N-dimethylformamide, 1200 μL of dimethyl sulfoxide and 2468 μL of 1-butyl-3-methylimidazole Tetrafluoroborate, then add 452 μL of ethylene glycol dimethacrylate and 64 μL of 4-vinylpyridine, and finally add 20 mg of free radical initiator azobisisobutyronitrile, ultrasonic for 20 minutes to remove the dissolved Oxygen in it, after the solution is completely mixed, transfer the solution to a stainless steel column (100mm in length, 4.6mm in diameter), quickly seal both ends of the stainless steel column, and react in a constant temperature water bath at a temperature of 60°C for 18 hours;

[0030] b. Take out the synthesized stainless steel column from the water bath, install the column head, connect it to the high-pressure infusion pump, wash the whole column with a mixture of methanol-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com