Waste battery piece recycling process

A waste battery and process technology, applied in the direction of waste treatment, solid waste removal, etc., can solve the problems of low benefit, increased cost, and low possibility of reusing finished products, achieve high economic value, reduce production costs, and reduce The effect of cost recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

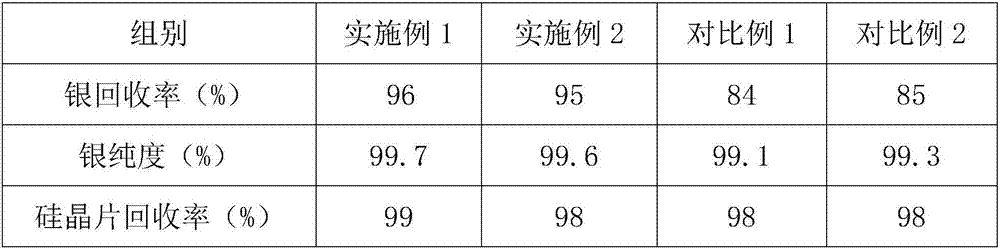

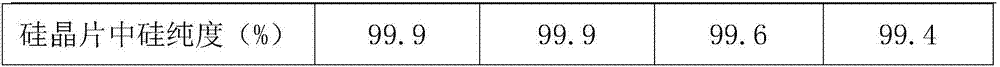

Examples

Embodiment 1

[0020] 1) Removing the aluminum layer: Soak the crystalline solar cell chip in waste lye with a concentration of 5% discharged from the solar cell production line for 2 hours and at a temperature of 60°C to remove the aluminum layer on the aluminum back field of the solar cell chip. The solid-liquid mass ratio of the battery chip to the waste lye is 1kg:1L;

[0021] 2) Removing the silver layer: Soak the aluminum-free battery chip with a nitric acid solution with a concentration of 3%, for 6 hours at a temperature of 80° C., and leaching the Ag on the surface of the battery to obtain a silver-containing acid solution and a silver-removed battery. The silver-removed battery sheet is taken out, and the solid-to-liquid mass ratio of the crystalline silicon solar cell chip to the nitric acid solution is 1kg:1.2L;

[0022] 3) silver powder recovery: in the silver nitrate solution obtained, add the hydrochloric acid solution that concentration is 10%, take out silver nitrate precipi...

Embodiment 2

[0026] 1) Removing the aluminum layer: Soak the crystalline solar cell chip in waste lye with a concentration of 3-5% discharged from the solar cell production line for 2 hours at a temperature of 40°C, remove the aluminum layer on the aluminum back field of the solar cell chip, and crystalline The solid-to-liquid mass ratio of the silicon solar cell chip to the waste lye is 1kg:1L;

[0027] 2) Removing the silver layer: Soak the aluminum-free battery chip with a nitric acid solution with a concentration of 3%, for 6 hours at a temperature of 50° C., and leaching the Ag on the surface of the battery to obtain a silver-containing acid solution and a silver-removed battery. The silver-removed battery sheet is taken out, and the solid-to-liquid mass ratio of the crystalline silicon solar cell chip to the nitric acid solution is 1kg:1.2L;

[0028] 3) silver powder recovery: in the silver nitrate solution obtained, add the hydrochloric acid solution that concentration is 10%, take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com