Preparation method of sludge biocharcoal water permeable brick with high adsorption performance

A biochar, high adsorption technology, applied in the direction of adsorption of water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of high moisture content and organic matter content, low sludge content of a single brick, pollution Low utilization rate of mud and other problems, achieve strong adsorption capacity, not easy to be broken and lost, and prevent and control groundwater pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

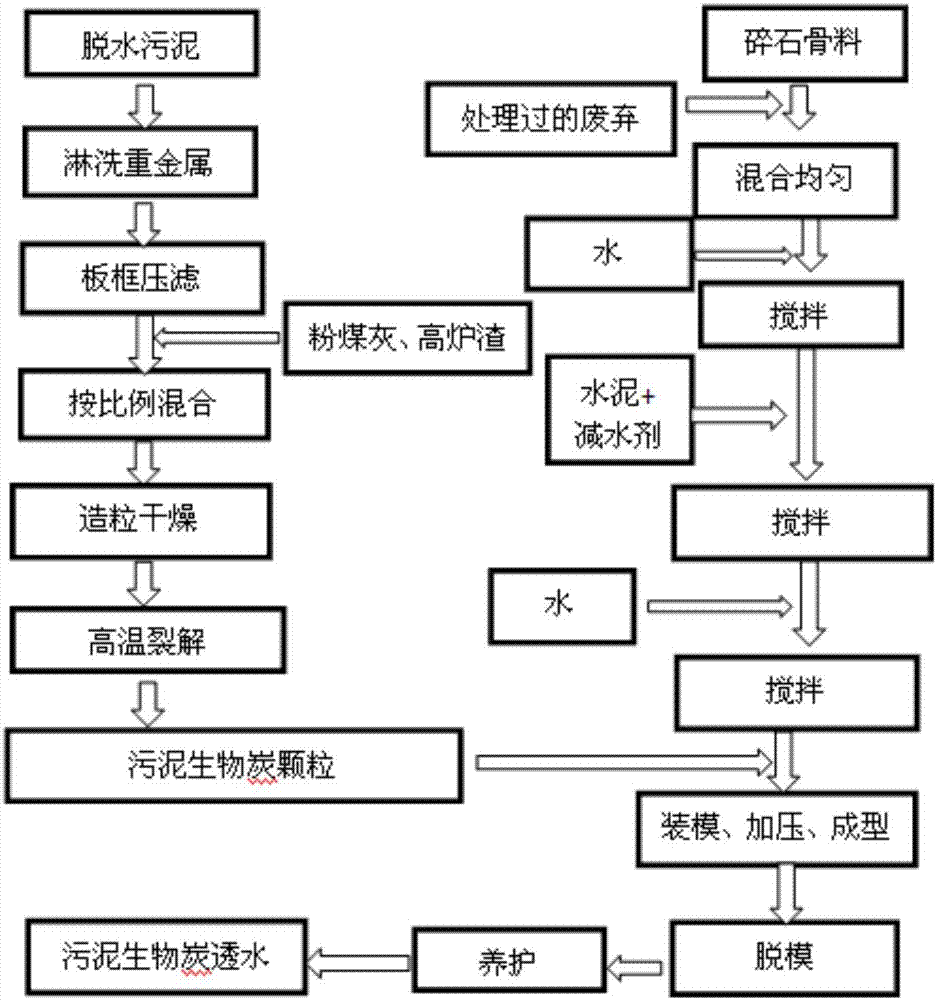

[0028] 1) After dehydration treatment of urban sewage treatment plant sludge or water dredging sludge, add 0.05mol / L ethylenediaminetetraacetic acid solution and 0.1mol / L humic acid solution, and the amount of eluent per 1kg of sludge is 2L , leaching to remove some heavy metals;

[0029] 2) Plate and frame filter the sludge treated with the eluting agent, then add fly ash or blast furnace slag, and mix according to the mass ratio of sludge: fly ash or blast furnace slag at a ratio of 15:1;

[0030] 3) Granulation and drying, made into granules with a particle size of 5mm, air-dried naturally, or dried in a dryer, and the moisture content is reduced to below 10%;

[0031] 4) Place the dried material in step 3) in a pyrolysis device, heat up to 600°C under anaerobic conditions, and after firing for 4 hours, cool down to 27°C to obtain sludge biochar;

[0032] 5) Take the waste fabric according to 2% of the volume of the 7mm crushed stone aggregate, and cut it into strips with ...

Embodiment example 2

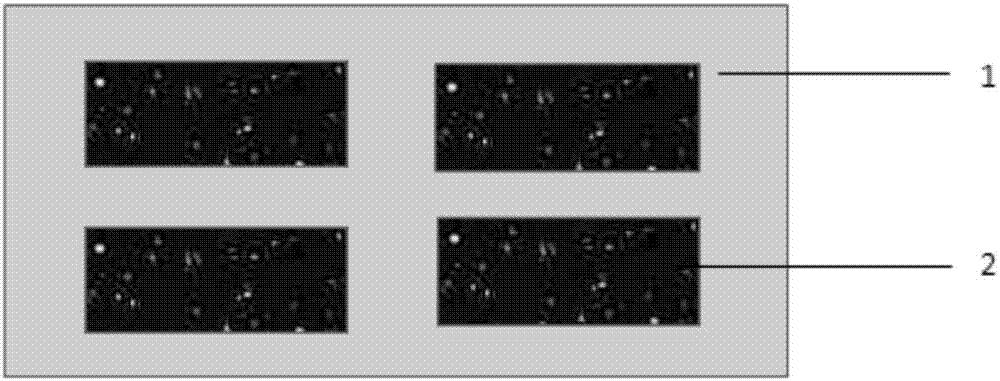

[0039] Implementation case 2, the preparation of permeable bricks for water body slopes. The main function of this type of permeable bricks is water purification and exchange, and does not need to have high strength. Therefore, the proportion of biochar can be increased to about 33.33% when installing the mold, and the mold should be installed according to the ratio of biochar: concrete = 1:2, and the thickness of the concrete layer on the brick surface can be reduced to 1cm.

[0040] The addition of waste fabrics in the present invention can make the connection between sludge biochar particles more tightly, improve the strength of sludge biochar bricks, and reduce the crushing and loss of sludge biochar. The purpose of plate and frame filter press is to Heavy metals activated by leaching agent or chelated are removed from the sludge. The concrete material made of crushed stone aggregate, strip fabric and cement ensures the pressure resistance and strength of the permeable bric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com