Dual-band detector based on indium selenide and gallium nitride and its preparation method

A dual-band detector, indium selenide technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as increasing detection difficulty, high power consumption, and reducing detection efficiency, and achieve improved diffusion effects. , the effect of reducing power consumption and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

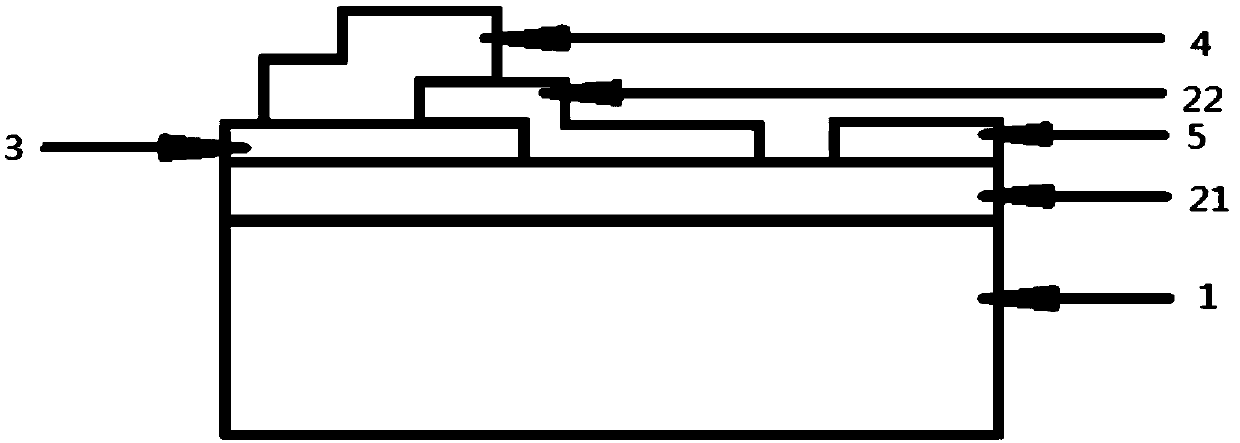

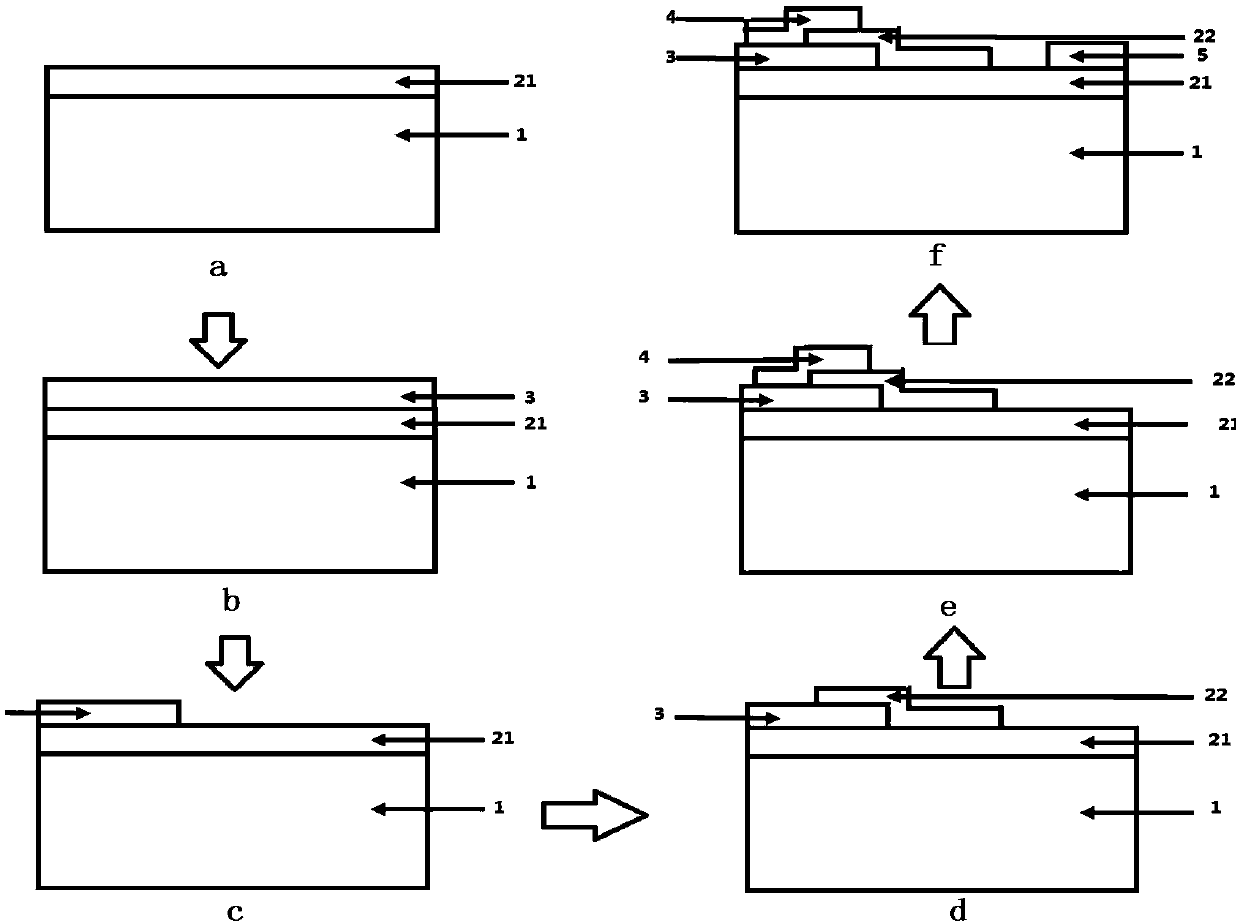

[0039] Example 1: Using a sapphire substrate to complete the fabrication of a dual-band detector based on indium selenide and gallium nitride

[0040] Step 1, growing an ultraviolet absorbing layer 21 .

[0041] 1a) Prepare an acetone suspension of gallium oxide, drop it evenly on a clean sapphire substrate with a rubber dropper, and let it dry naturally;

[0042] 1b) Put the sapphire substrate into the quartz boat, and put the quartz boat into the thermostatic tube furnace;

[0043] 1c) After the tube furnace is evacuated, argon gas is introduced to make the pressure in the furnace be one atmosphere, and the temperature is raised to 1000°C and maintained;

[0044] 1d) At 1000°C, flow ammonia gas with a flow rate of 60 sccm for 1 hour, close the tube furnace and cool down to room temperature to obtain a yellow thin-film gallium nitride sample attached to the sapphire substrate, forming an ultraviolet absorbing layer on the sapphire substrate 21, such as figure 2 a.

[004...

Embodiment 2

[0060] Embodiment 2: A silicon substrate is used to complete the fabrication of a dual-band detector based on indium selenide and gallium nitride.

[0061] Step 1, growing an ultraviolet absorbing layer 21 .

[0062] 1.1) Prepare an acetone suspension of gallium oxide, drop it evenly on the silicon wafer with a crystal orientation of 111 with a rubber dropper, and let it dry naturally;

[0063] 1.2) Complete the fabrication of the ultraviolet absorbing layer 21 positioned on the silicon substrate according to the same operation as that of step 1b)-1d) of embodiment 1, such as figure 2 a.

[0064] Step 2, depositing an insulating layer 3 .

[0065] On the gallium nitride film attached to the silicon substrate 1 obtained in step 1, a thin layer of aluminum oxide with a thickness of 40 nm is deposited to obtain an insulating layer 3, such as figure 2 b.

[0066] Step 3, etching the insulating layer 3 .

[0067] The specific implementation of this step is the same as that o...

Embodiment 3

[0076] Embodiment 3: A silicon carbide substrate is used to complete the fabrication of a dual-band detector based on indium selenide and gallium nitride.

[0077] Step A, growing the ultraviolet absorbing layer 21 .

[0078] A1) Prepare an acetone suspension of gallium oxide, drop it evenly on a clean silicon carbide substrate with a rubber dropper, and let it dry naturally;

[0079] A2) Complete the fabrication of the ultraviolet absorbing layer 21 located on the silicon carbide substrate according to the same operation as in step 1b)-1d) of embodiment 1, such as figure 2 a.

[0080] Step B, depositing an insulating layer 3 .

[0081] Depositing a thin layer of aluminum oxide with a thickness of 30 nm on the gallium nitride film attached to the silicon carbide substrate obtained in step 1 to obtain an insulating layer 3;

[0082] Step C, etching the insulating layer 3 .

[0083] The specific implementation of this step is the same as that of step 3 in Embodiment 1.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com