Preparation method of feed-grade methionine hydroxy manganese chelate

A hydroxymethionine manganese chelate, feed-grade technology, which is applied in the field of feed additive preparation, can solve the problems of inability to guarantee product quality, mixed with impurities in products, difficult to popularize, etc., and achieves the effects of high speed, reduced production cost, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

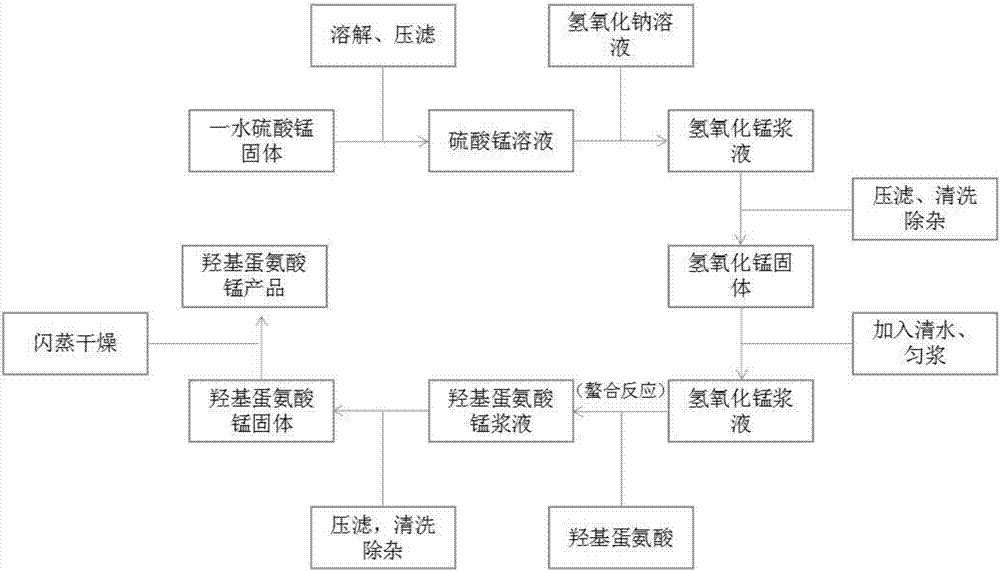

Image

Examples

Embodiment 1

[0029] Prepare feed grade hydroxymethionine manganese chelate product A according to the following method:

[0030] (1) Dissolving the solid manganese sulfate monohydrate, removing the insolubles by means of pressure filtration to obtain manganese sulfate solution.

[0031] (2) Add sodium hydroxide solution to the manganese sulfate solution, collect the solid phase matter by pressure filtration after fully reacting, and then wash away the sodium sulfate contained in the solid phase matter, sodium hydroxide and other soluble substances by washing , using barium chloride to detect whether the sulfate radicals have been rinsed clean, to obtain water-washed slag.

[0032] (3) Transfer the water-washed slag into a reaction tank, and add clear water to homogenate. The manganese content of the extracted homogenate was 23.3% (mass percentage).

[0033] (4) By measuring the manganese content, the chelation reaction was carried out according to the molar ratio of manganese to hydroxym...

Embodiment 2

[0038] Prepare feed grade hydroxymethionine manganese chelate product B according to the following method:

[0039] (1) Dissolving solid manganese chloride tetrahydrate, removing insoluble matter by pressure filtration, to obtain manganese chloride solution.

[0040] (2) Add sodium hydroxide solution in the manganese chloride solution, collect the solid phase matter by press filtration after fully reacting, then wash the sodium chloride contained in the solid phase matter, soluble substances such as sodium hydroxide Rinse well to obtain washed residue.

[0041] (3) Transfer the water-washed slag into a reaction tank, and add clear water to homogenate. The manganese content of the extracted homogenate was 25.1% (mass percentage).

[0042] (4) By measuring the manganese content, the chelation reaction was carried out according to the molar ratio of manganese to hydroxymethionine of 1:2.1, the reaction temperature was 25°C, the reaction time was 20 minutes, the stirring speed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com