Electrolyte for zinc ion hybrid supercapacitor, and zinc ion hybrid supercapacitor and preparation method thereof

A supercapacitor and electrolyte technology, which is applied in the manufacture of hybrid capacitor electrolytes, hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve problems such as electrolyte leakage, device aging, low operating voltage, etc., and achieve a lifespan that is not easy to leak , high working voltage and good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] In a preferred embodiment, the preparation method comprises the following steps:

[0077] a) Prepare the negative electrode: use zinc, zinc alloy or zinc and non-metallic composite material of required size as the negative electrode after surface treatment;

[0078] b) preparing electrolyte: dissolving zinc salt in organic solvent and / or ionic liquid, and fully stirring to obtain electrolyte;

[0079] c) Preparing a diaphragm: using a porous polymer film, an inorganic porous film or an organic / inorganic composite film of a required size as a diaphragm;

[0080] d) Preparation of positive electrode: positive electrode active material, conductive agent and binder are made into positive electrode slurry or positive electrode sheet material; then the positive electrode slurry is coated on the surface of the positive electrode current collector or the positive electrode sheet material is pressed on the positive electrode current collector surface, dried to obtain a positive...

Embodiment 1

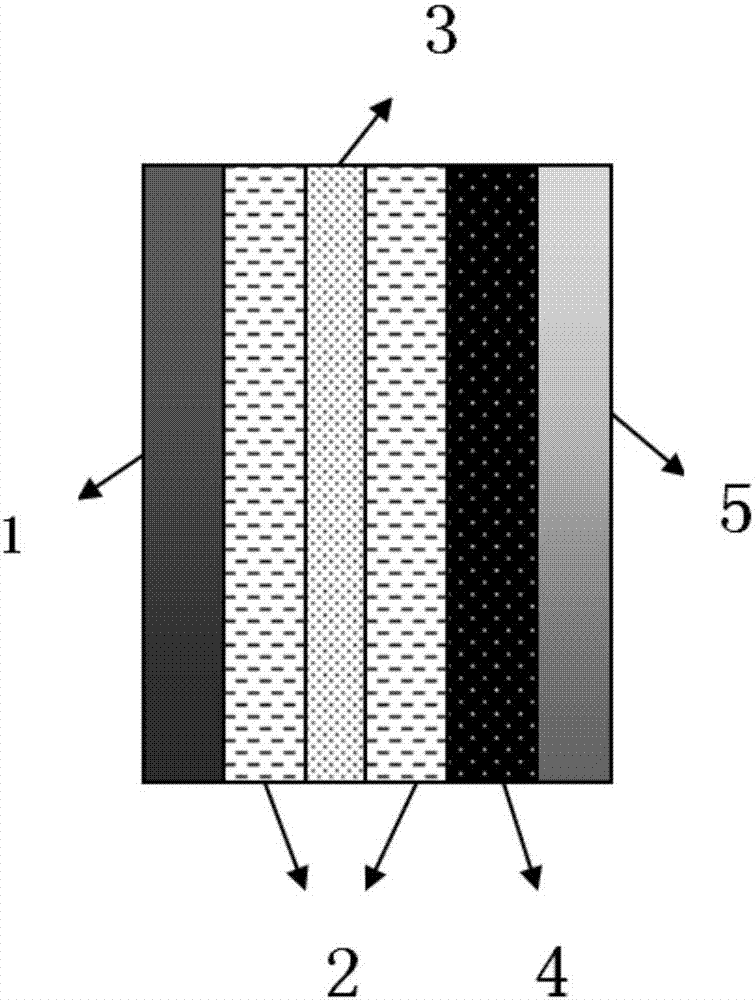

[0086] A zinc ion hybrid supercapacitor, including a negative electrode, a diaphragm, an electrolyte, a positive electrode and a casing;

[0087] The negative electrode includes a negative electrode active material and a negative electrode current collector, both of which are zinc foil; the separator is glass fiber; the electrolyte is zinc trifluoromethanesulfonate (Zn(CF 3 SO 3 ) 2) and 2-dimethoxyethane (DME) and 1,3-dioxolane (DOL) mixed solution; positive electrode includes positive electrode material and positive electrode current collector, and positive electrode material includes activated carbon (positive electrode active material), acetylene black (conductive agent) and polyvinylidene fluoride (binder), and the positive current collector is aluminum foil.

[0088] The above-mentioned zinc ion hybrid supercapacitor is mainly prepared by the following method:

[0089] Preparation of negative electrode: take zinc foil with a thickness of 0.2 mm, cut it into discs with...

Embodiment 2

[0095] A zinc ion hybrid supercapacitor, including a negative electrode, a diaphragm, an electrolyte, a positive electrode and a casing;

[0096] The negative electrode includes a negative electrode active material and a negative electrode current collector, both of which are zinc foil; the separator is glass fiber; the electrolyte is zinc trifluoromethanesulfonate (Zn(CF 3 SO 3 ) 2 ) and 2-dimethoxyethane (DME) and 1,3-dioxolane (DOL) mixed solution; positive electrode includes positive electrode material and positive electrode current collector, and positive electrode material includes activated carbon (positive electrode active material), acetylene black (conductive agent) and polyvinylidene fluoride (binder), and the positive current collector is aluminum foil.

[0097] The above-mentioned zinc ion hybrid supercapacitor is mainly prepared by the following method:

[0098] Preparation of negative electrode: take zinc foil with a thickness of 0.2 mm, cut it into discs wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com