Pt-Sn supported hydrotalcite dehydrogenation catalyst and preparation method and application thereof

A dehydrogenation catalyst, hydrotalcite technology, applied in catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve a simple preparation process, enhanced dehydrogenation activity, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

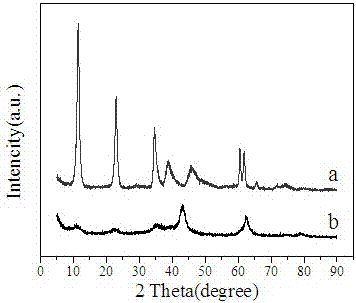

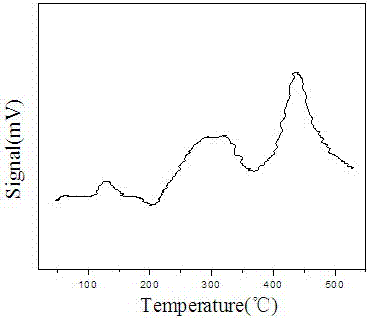

Image

Examples

Embodiment 1

[0025] Weigh 3.84g of magnesium nitrate and 1.88g of aluminum nitrate, dissolve them together in 40mL of deionized water, and configure them as Mg 2+ / Al 3+ Metal salt solution A with a molar ratio of 3; weigh 2.4g sodium hydroxide and 0.4g anhydrous sodium carbonate, dissolve them in 50mL of deionized water together, configure alkali solution B, and pour A and B solutions into Two constant pressure titration funnels are connected with a three-necked flask and a constant speed stirrer. Under the conditions of room temperature and high-speed stirring, slowly drop the A and B solutions in the constant pressure titration funnel into the three-necked flask at a speed of 3mL / min, make them fully mixed, and control the pH of the suspension at 9.5~ 10.5, and then continue to stir at high speed for 30 minutes. Then transfer the suspension to a 200mL hydrothermal reaction kettle, crystallize at 95°C for 10h, take it out for suction filtration, wash with water and alcohol three times ...

Embodiment 2

[0028] According to the preparation method and reaction conditions of catalyst in embodiment 1, Mg 2+ / Al 3+ The molar ratio is adjusted to 1:1, the loading amount of platinum is adjusted to 5%, the loading amount of tin is adjusted to 2wt%, the calcination temperature is adjusted to 600 ° C, and other conditions are unchanged, the dehydrogenation reaction of methylcyclohexane is carried out, The dehydrogenation conversion rate of methylcyclohexane after continuous reaction for 10 h was 91.0%, the selectivity of toluene was 99.9%, and the hydrogen release rate of the catalyst was 263.5 mmol H 2 g -1 cat. h -1 .

Embodiment 3

[0030] According to the preparation method and reaction conditions of catalyst in embodiment 1, Mg 2+ / Al 3+ The molar ratio of the molar ratio is adjusted to 4:1, the loading of platinum is adjusted to 0.5%, the loading of tin is changed to 0.1wt%, and other conditions are unchanged, the dehydrogenation reaction of methylcyclohexane is carried out, and the formazan after continuous reaction 10h The dehydrogenation conversion rate of cyclohexane was 65.0%, the selectivity of toluene was 99.9%, and the hydrogen release rate of the catalyst was 188.2 mmol H 2 g -1 cat. h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com