Energy-saving real stone paint and preparation method thereof

A technology of real stone and additives, applied in the field of real stone energy-saving paint and its preparation, can solve the problems of unsatisfactory thermal insulation effect of real stone paint, polluting urban ecological environment, affecting building safety, etc. Low coefficient, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

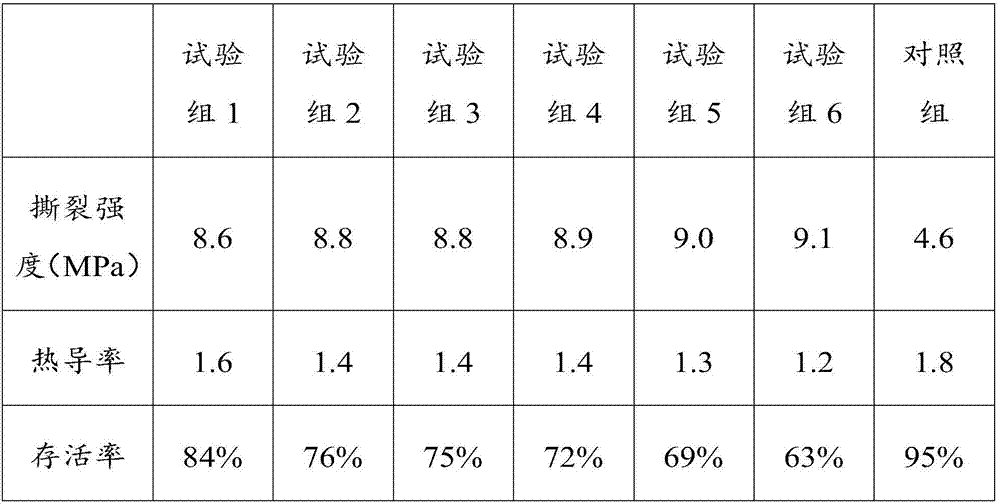

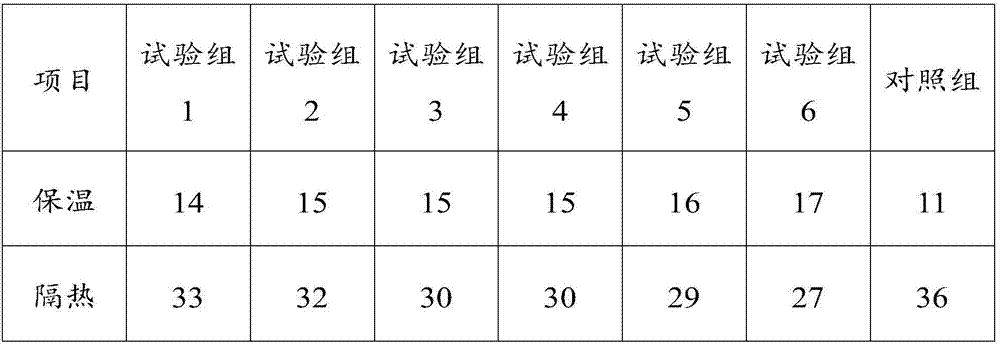

Examples

preparation example Construction

[0050] In addition, this embodiment also provides a method for preparing the above-mentioned real stone energy-saving paint, which may include the following steps: mixing the resin with the organic phosphine / bromine complex, curing to obtain a cured resin, and then combining the cured resin with the filler and the remaining The additives are mixed to obtain the real stone energy-saving paint.

[0051] Specifically, the resin is cured by reacting at 118-122°C for 45-50 minutes. Under this condition, the cured resin is colorless, transparent and has the best yellowing resistance and stability. At the same time, it has a low solar energy absorption rate. .

[0052] Further, during the preparation process, the solidified resin and the filler can be mixed at a stirring speed of 500-700r / min, and then mixed with the remaining additives and the ultrasonic frequency is 100-120KHz, and the stirring speed is 200-280r / min. Mix under the condition of min. This mixing sequence is better than ...

Embodiment 1

[0058] 25 parts by weight of a fluorine-containing resin with a transparency of 90% and 4 parts by weight of an organic phosphine / bromine complex are mixed, and reacted at 118° C. for 50 minutes to obtain a cured resin. The cured resin is mixed with 20 parts by weight of the filler under the condition of 500r / min, and then mixed with the remaining additives under the conditions of an ultrasonic frequency of 100KHz and a stirring speed of 280r / min to obtain a real stone energy-saving paint.

[0059] Among them, the filler contains silica, barite, talc and metal oxide composite in a weight ratio of 1:1:1.4:0.6. The particle size of the above fillers are all 150 nm. The metal oxide composite contains manganese dioxide, nickel oxide, cobalt oxide, chromium trioxide, lanthanum trioxide, and aluminum oxide in a weight ratio of 1.8:1.4:1.4:2:1.7:1.5. The remaining additives contain 2 parts by weight of sodium tripolyphosphate, 5 parts by weight of water glass, 1 part by weight of acryl...

Embodiment 2

[0061] 25 parts by weight of a fluorine-containing resin with a transparency of 90% and 4 parts by weight of an organic phosphine / bromine complex are mixed, and reacted at 118° C. for 50 minutes to obtain a cured resin. The cured resin is mixed with 20 parts by weight of the filler under the condition of 500r / min, and then mixed with the remaining additives under the conditions of an ultrasonic frequency of 100KHz and a stirring speed of 280r / min to obtain a real stone energy-saving paint.

[0062] Among them, the filler contains Danqiang silk, calcium sulfate whiskers, zeolite powder, slag powder, silica, barite, talc powder and metals in a weight ratio of 1:1:1.4:0.6:3:4:1:2. Oxide complex. The particle size of the above fillers are all 150 nm. The metal oxide composite contains manganese dioxide, nickel oxide, cobalt oxide, chromium trioxide, lanthanum trioxide, and aluminum oxide in a weight ratio of 1.8:1.4:1.4:2:1.7:1.5. The remaining additives contain 2 parts by weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com