Intensive cultivation tail water treatment system

A treatment system and tail water technology, applied in the field of intensive aquaculture tail water treatment system, can solve the problems of increasing environmental impact, high nitrogen and phosphorus indicators, and unsatisfactory effects, so as to promote photosynthesis and growth, The effect of improving capacity and reducing the cost of tail water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

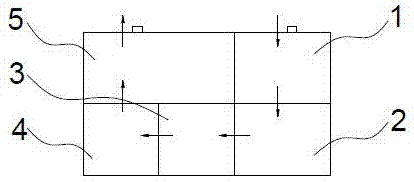

[0018] Such as figure 1 As shown, an intensive aquaculture tail water treatment system includes ponds connected in sequence, and the ponds are in order: in-situ sedimentation tank 1, biological treatment tank 2, aeration tank 3, culture ponds 4 and 5, and in-situ sedimentation tank 1 , the biological treatment tank 2, the aeration tank 3, and the culture tank 4 and 5 are connected by connecting pipes, the connecting pipes are provided with valves, the biological treatment tank 2 is provided with evenly distributed ropes or stakes, and the surface of the ropes is provided with uniform The float of the cloth has biofilm or active sludge suspended on the surface of the float or stake, and the number of replacement of the biofilm or activated sludge suspended on the surface of the float or stake is 8 days / time, and the aeration tank 3 is provided with an aeration device and algae, The tail water salinity of culture ponds 4 and 5 is 16. In-situ sedimentation tank 1, biological trea...

Embodiment 2

[0026] Such as figure 1As shown, an intensive aquaculture tail water treatment system includes ponds connected in sequence, and the ponds are in order: in-situ sedimentation tank 1, biological treatment tank 2, aeration tank 3, culture ponds 4 and 5, and in-situ sedimentation tank 1 , the biological treatment tank 2, the aeration tank 3, and the culture tank 4 and 5 are connected by connecting pipes, the connecting pipes are provided with valves, the biological treatment tank 2 is provided with evenly distributed ropes or stakes, and the surface of the ropes is provided with uniform The float of the cloth, the surface of the float or the pile is suspended with biofilm or active sludge, the number of replacement of the biofilm or activated sludge suspended on the surface of the float or the pile is preferably 7 days / time, and the aeration tank 3 is provided with an aeration device and algae , the salinity of the tail water in the culture ponds 4 and 5 is preferably 15, the in-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com