Polymer, composition for organic electroluminescent element, organic electroluminescent element, organic el display device, and organic el illumination

An electroluminescent element and polymer technology, applied in the field of polymers, can solve the problems of not yet reaching a practical level, poor driving stability, difficult lamination by wet film-forming methods, etc., achieving excellent electrochemical stability and long driving life. , the effect of high technical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0389] [Synthesis of Monomer (Compound 3)]

[0390] Compound 1 was synthesized as follows.

[0391] Synthesis of monomer

[0392] [chemical 16]

[0393]

[0394] Put 4-sec-butylaniline (37.36g, 250.34mmol), bromobenzene (38.52g, 245.33mmol) and sodium tert-butoxide (57.77g, 601.05mmol), toluene (500ml) into the flask, fully carry out Replaced with nitrogen, heated to 60°C (Solution A). Add 1,1'-bis(diphenylphosphino)ferrocene ( 1.09g, 1.96mmol), heated to 60°C (solution B). Solution B was added to Solution A in a nitrogen stream, and stirred at 100° C. for 4.0 hours. After naturally cooling to room temperature, ethyl acetate (300ml) and brine (100ml) were added to the reaction solution and stirred, followed by liquid separation, and the aqueous layer was extracted with ethyl acetate (100ml×2 times), the organic layers were combined, and washed with Concentrate after drying over magnesium sulfate. Furthermore, purification was carried out by silica gel column chromato...

Embodiment 2

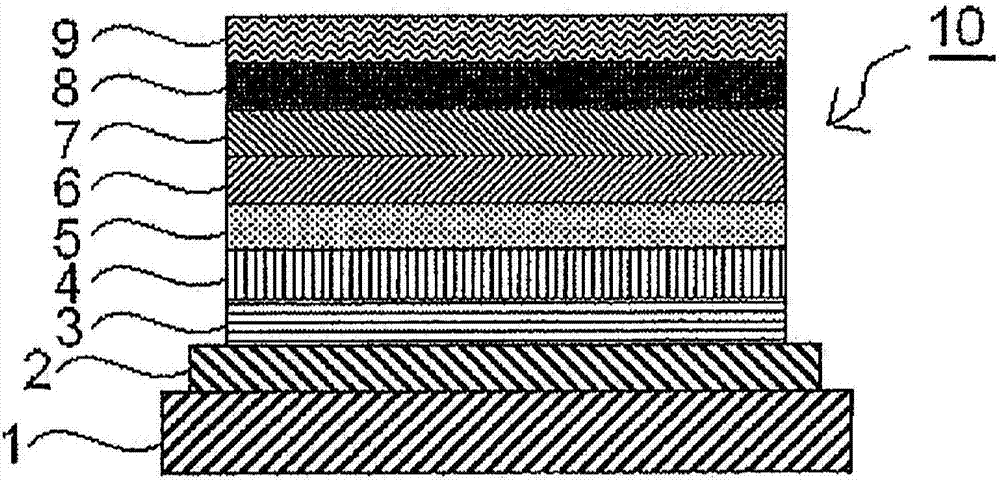

[0413] make out figure 1 The organic electroluminescence device shown.

[0414] After depositing an indium tin oxide (ITO) transparent conductive film on the glass substrate 1 by sputtering, it patterned 2mm-wide stripes using common photolithography and hydrochloric acid etching to form an anode with a film thickness of 70nm. 2. After the patterned ITO substrate was cleaned in the order of ultrasonic cleaning with aqueous surfactant solution, water washing with ultrapure water, ultrasonic cleaning with ultrapure water, and water washing with ultrapure water, it was dried with compressed air, Finally, ultraviolet ozone cleaning is carried out.

[0415] Next, the polymer 1 (P1) synthesized in Example 1, 4-isopropyl-4'-methyldiphenyliodonium tetrakis(pentafluorophenyl)boronic acid shown in structural formula (A1) was prepared A coating solution for forming a hole injection layer of a salt and ethyl benzoate. This coating solution was formed into a film on the anode 2 by spin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com