Copper oxide/graphene composite material, preparation method thereof and application of composite material

A composite material and graphene technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, separation methods, etc., can solve problems such as difficult to effectively remove pollutants, expensive equipment, complicated methods, etc., and achieve good results The effect of application prospect, simple preparation process and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

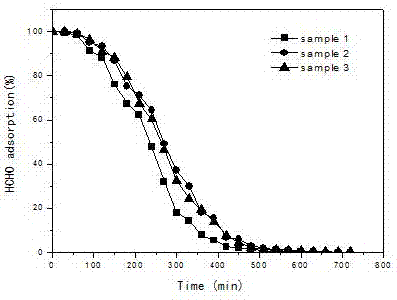

Embodiment 1

[0027] (1) Add 2g of graphene oxide into 200mL of deionized water, and ultrasonically disperse. The ultrasonic treatment time is 60min, and the ultrasonic power is 150W, to obtain a graphene oxide dispersion;

[0028] (2) Add 25g of copper nitrate trihydrate into 100mL of deionized water, and slowly add 12mol / L of concentrated ammonia water dropwise while stirring to adjust the pH value to 9 to form a stable copper ammonia solution [Cu(NH 3 ) 4 (H 2 O) 2 ] 2+ ;

[0029] (3) Add the cuproammonia solution described in step (2) into the graphene oxide dispersion described in step (1), stir at room temperature for 30 min, and then o Continue heating under C condition for 2h; Then reactant is transferred to the autoclave with tetrafluoroethylene liner, at 180 oC Under carry out 5h hydrothermal reduction reaction;

[0030] (4) After the reaction solution in step (3) dropped to room temperature, the supernatant was removed, and the solid was washed with deionized water, suctio...

Embodiment 2

[0032] (1) Add 1g of graphene oxide into 200mL of deionized water, and ultrasonically disperse it. The ultrasonic treatment time is 30min, and the ultrasonic power is 150W, to obtain a graphene oxide dispersion;

[0033] (2) Add 17g of copper nitrate trihydrate into 100mL of deionized water, and slowly add 12mol / L of concentrated ammonia water dropwise while stirring to adjust the pH value to 9.5 to form a stable copper ammonia solution [Cu(NH 3 ) 4 (H 2 O) 2 ] 2+ ;

[0034] (3) Add the cuproammonia solution described in step (2) into the graphene oxide dispersion described in step (1), stir at room temperature for 50 min, and then o Continue heating under C condition for 2h; Then reactant is transferred to the autoclave with tetrafluoroethylene liner, at 150 oC Under carry out 8h hydrothermal reduction reaction;

[0035] (4) After the reaction solution in step (3) dropped to room temperature, the supernatant was removed, and the solid was washed with deionized water, f...

Embodiment 3

[0037] (1) Add 1g of graphene oxide into 200mL of deionized water, and ultrasonically disperse it. The ultrasonic treatment time is 60min, and the ultrasonic power is 150W, to obtain a graphene oxide dispersion;

[0038] (2) Add 10g of copper nitrate trihydrate into 100mL of deionized water, and slowly add 12mol / L of concentrated ammonia water dropwise while stirring to adjust the pH value to 9.2 to form a stable copper ammonia solution [Cu(NH 3 ) 4 (H 2 O) 2 ] 2+ ;

[0039] (3) Add the cuproammonia solution described in step (2) into the graphene oxide dispersion described in step (1), stir at room temperature for 60 min, and then o Continue heating under C condition for 2h; Then reactant is transferred to the autoclave with tetrafluoroethylene liner, at 180 oC Under carry out 8h hydrothermal reduction reaction;

[0040] (4) After the reaction solution in step (3) dropped to room temperature, the supernatant was removed, and the solid was washed with deionized water, fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com