Preparation method of super absorbent resin for removing water of oil products

A technology of superabsorbent resin and water-soluble acrylic acid, which is applied in the direction of fat oil/fat refining, chemical instruments and methods, dehydration/demulsification of hydrocarbon oil, etc. It can solve the problems of poor compatibility, swelling and cracking, difficult cleaning, etc., and achieve water absorption Stable performance, easy separation, rapid water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

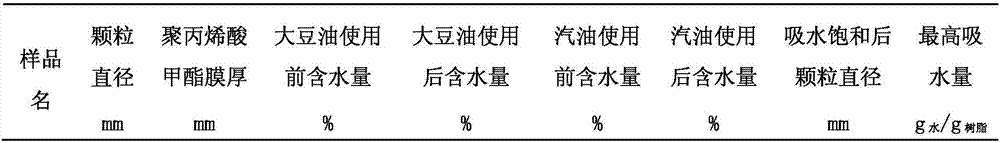

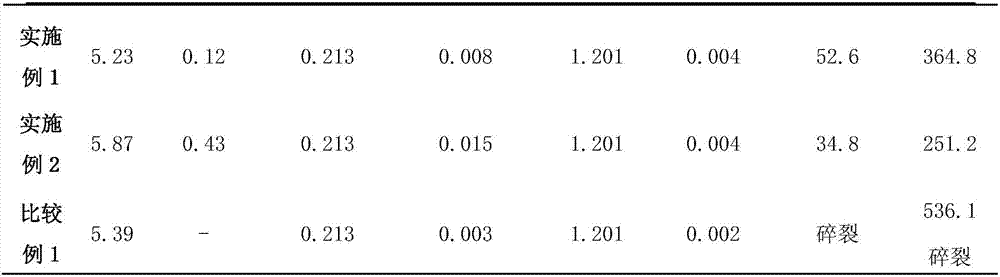

Embodiment 1

[0026] In the embodiment of the present invention, the specific steps of the preparation method of the superabsorbent resin are as follows:

[0027] (1) Slowly add sodium hydroxide solution with a concentration of 32wt% into acrylic acid to form a sodium acrylate solution with a neutralization degree of 80%;

[0028] (2) Add 0.2g of N-methylolacrylamide into 100g of sodium acrylate solution, heat to 65°C, stir for 1h, and cool to room temperature;

[0029] (3) Add 0.1g of hydroquinone and 0.1g of potassium persulfate to the sodium acrylate solution respectively, and stir for 1 hour at room temperature;

[0030] (4) Add 2g of Span 80, 5g of methyl acrylate and 0.5g of hydroquinone into 120g of cyclohexane and heat to 95°C, then add the sodium acrylate solution obtained in step (3) dropwise, and stir And use a water separator to remove water, and cool to room temperature after the reaction;

[0031] (5) The solid product in the reaction solution was separated, dried at 110° C....

Embodiment 2

[0033] In the embodiment of the present invention, the specific steps of the preparation method of the instantaneous superabsorbent resin are as follows:

[0034] (1) Slowly add sodium hydroxide solution with a concentration of 32wt% into acrylic acid to form a sodium acrylate solution with a neutralization degree of 80%;

[0035] (2) Add 0.2g of N-methylolacrylamide into 100g of sodium acrylate solution, heat to 65°C, stir for 1h, and cool to room temperature;

[0036] (3) Add 0.1g of hydroquinone and 0.1g of potassium persulfate to the sodium acrylate solution respectively, and stir for 1 hour at room temperature;

[0037] (4) Add 2 g of Span 80, 10 g of methyl acrylate and 0.5 g of hydroquinone into 120 g of cyclohexane and heat to 95° C., then add dropwise the sodium acrylate solution obtained in step (3), and stir And use a water separator to remove water, and cool to room temperature after the reaction;

[0038] (5) The solid product in the reaction solution was separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com