Digestion-resistant starch as well as preparation method and applications thereof

A technology of anti-digestible starch and starch, which is applied in pharmaceutical formulations, medical preparations of non-active ingredients, food science, etc., can solve the problems of small-scale carrier materials, unfavorable large-scale production, low production efficiency, etc., and achieve improved targeting Conveying efficiency, high degree of automation and controllability, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]Common cornstarch and phosphate buffer (pH 5.0) are formulated into starch slurry at a ratio of 5% by mass of starch. After gelatinization, put it into an enzyme membrane reactor. And the ultrafiltration membrane of the pullulanase immobilized 30ASPU / g starch carries out enzymolysis and ultrafiltration, processes 30min to obtain filtrate, adds the lauryl gallate of 5% starch dry basis mass in filtrate, 60 ℃, under 0.5MPa Mix for 30 minutes. Finally, wash with 70% ethanol and dry to obtain the product.

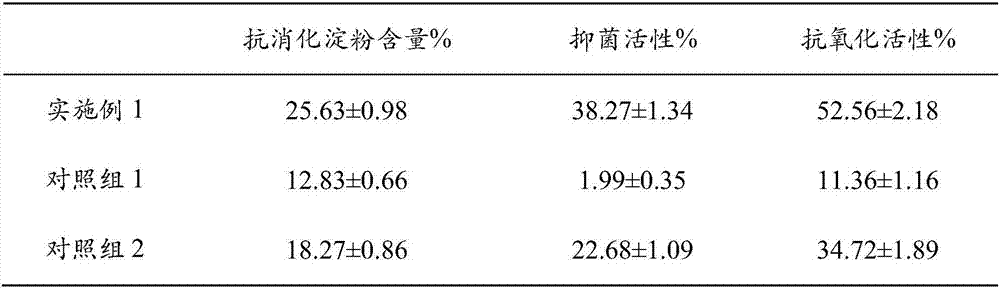

[0028] The digestibility of the digestible starch prepared in this example was measured by Englyst method; the antibacterial activity of starch-lauryl gallate was measured by calculating the total number of Staphylococcus aureus colonies in the culture medium; the antioxidant activity of the complex was measured by DPPH method. The control sample was common corn starch.

[0029] Measured through testing, the product anti-digestive starch content prepared in this embodim...

Embodiment 2

[0031] Potato starch and phosphate buffer solution (pH 6.0) are made into starch slurry according to the ratio of starch mass percentage of 8%. After gelatinization, put it into the enzyme membrane reactor. The ultrafiltration membrane of the pullulanase immobilized 35ASPU / g starch carries out enzymolysis and ultrafiltration, processes 50min and obtains ultrafiltration, adds ascorbyl palmitate of 10% starch dry weight in filtrate, 70 ℃, under 4.5MPa With 100min. Finally, wash with 70% ethanol and dry to obtain the product.

[0032] The digestibility of the digestible starch prepared in this example was determined by Englyst method; the antibacterial activity of starch-ascorbyl palmitate was measured by calculating the total number of Staphylococcus aureus colonies in the culture medium; the antioxidant activity of the complex was determined by DPPH method. The control sample was potato starch.

[0033] Measured through testing, the product anti-digestive starch content prepa...

Embodiment 3

[0035] Tapioca starch and phosphate buffer solution (pH 4.8) are made into starch slurry according to the ratio of starch mass percentage of 10%. After gelatinization, put it into the enzyme membrane reactor. The ultrafiltration membrane of the isoamylase immobilized 45 ASPU / g starch carries out enzymolysis and ultrafiltration, obtains filtrate after processing 110min, adds the lauryl gallate of 15% starch dry weight in filtrate, 70 ℃, under 6MPa With 80min. Finally, wash with 70% ethanol and dry to obtain the product.

[0036] The digestibility of the digestible starch prepared in this example was measured by Englyst method; the antibacterial activity of starch-lauryl gallate was measured by calculating the total number of Staphylococcus aureus colonies in the culture medium; the antioxidant activity of the complex was measured by DPPH method. The control sample was tapioca starch.

[0037] Measured through testing, the product anti-digestive starch content prepared in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com