Non-cyanide leaching agent and method for gold mine leaching thereof

A leaching agent, non-cyanide technology, applied in the field of non-cyanide extraction of gold ore, can solve the problems of small range of applicable ore samples, strong acidity of the leaching agent, instability of the leaching agent, etc., to achieve favorable leaching effect, high leaching pH, pH Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

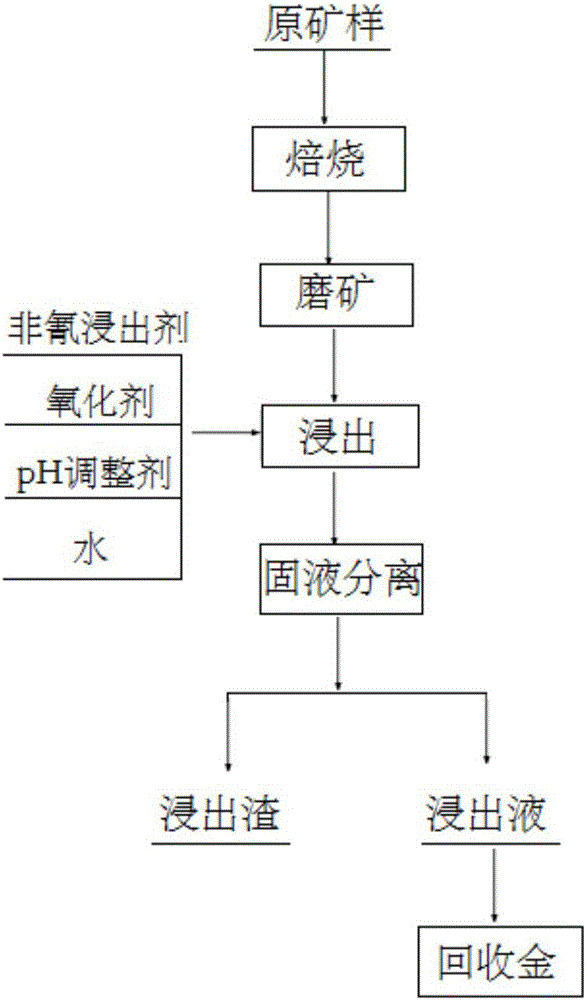

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 non-cyanide leaching agent and gold ore leaching

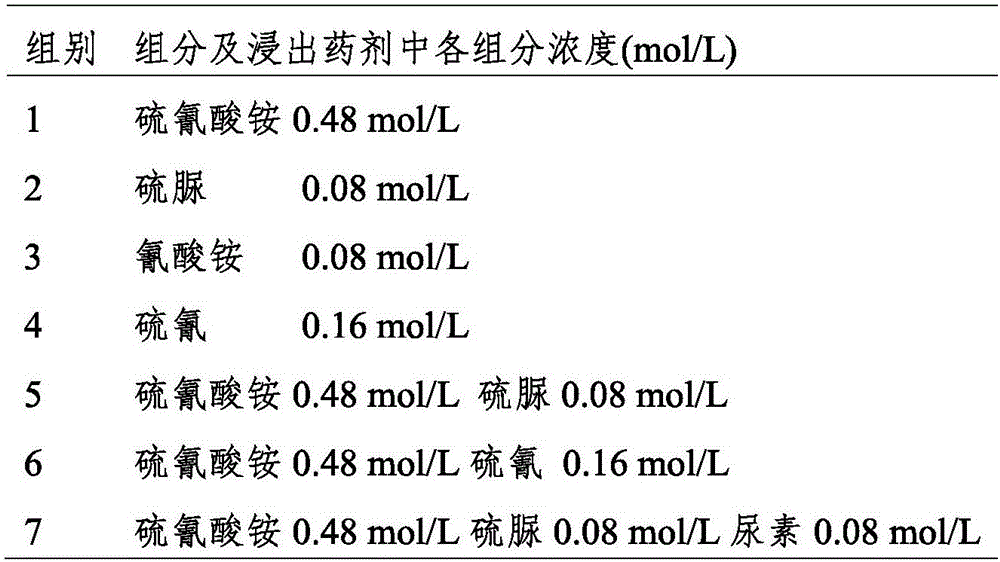

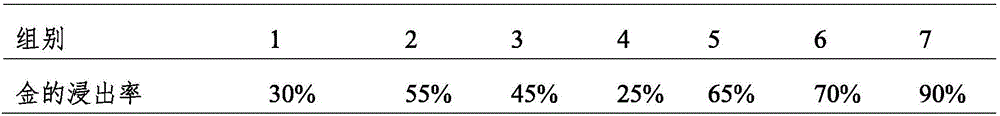

[0043] Mix ammonium thiocyanate, thiourea, thiocyanate and ammonium cyanate in a molar ratio of 6:1:2:1 to prepare a non-cyanide leaching agent.

[0044] The gold mineral in this embodiment is sulfide ore flotation gold concentrate, the gold ore contains 9.206%, 12.694%, and 2.7% of sulfur, iron, and arsenic respectively, and the gold grade is 98.34g / t, which is a high-sulfur and high-arsenic gold ore . Phase analysis shows that the metal minerals are 42.71% pyrite, 1.26% rutile, 5.62% arsenopyrite, and trace amounts of chalcopyrite, sphalerite and gold minerals. The gangue minerals are mainly quartz and feldspar, of which the quartz mineral content is 45.19%, and the feldspar content is 3.59%. In addition, the gangue minerals also contain a small amount of sericite and chlorite.

[0045] Take 50g of the above-mentioned refractory gold concentrate into a crucible, roast it in a muffle furnace at 750°C for...

Embodiment 2

[0048] Embodiment 2 non-cyanide leaching agent and gold ore leaching

[0049] Mix ammonium thiocyanate, thiourea, thiocyanate and ammonium cyanate in a molar ratio of 5:1:3:1 to prepare a non-cyanide leaching agent.

[0050] The gold mineral in this embodiment is sulfide ore flotation gold concentrate, the gold ore contains 16.29% sulfur and 26.694% iron respectively, and the gold grade is 64.79g / t, which is sulfide ore gold ore. Phase analysis shows that the metal minerals are mainly 51.31% pyrite, and trace amounts of chalcopyrite, galena and sphalerite. The gangue minerals are mainly quartz and feldspar, of which the quartz mineral content is 42.38%, and the feldspar content is 4.03%. In addition, the gangue minerals also contain a small amount of mica.

[0051] Take 200g of the above-mentioned refractory gold concentrate into a crucible, roast it in a muffle furnace at 700°C for 1 hour, and then take it out after cooling. The roasted ore was milled in a ball mill with wa...

Embodiment 3

[0054] Embodiment 3 non-cyanide leaching agent and gold ore leaching

[0055] Mix potassium thiocyanate, thiourea, thiocyanate and sodium cyanate in a molar ratio of 8:0.5:0.5:1 to prepare a non-cyanide leaching agent.

[0056] The gold minerals in this embodiment are sulfide ore flotation gold concentrates, and the main metal minerals in the ore are pyrite, arsenopyrite and a small amount of galena, sphalerite and chalcopyrite. Non-metallic minerals are quartz, chlorite, calcite and a small amount of garnet, fluorite, muscovite and so on. The main chemical composition of gangue minerals in the ore is SiO 2 , CaO, Al 2 o 3 , The content is 47.28%, 6.72%, 5.81%. The main elements of metal minerals are TFe, S, As, the element content is 11.45%, 7.41%, 2.45%, and the original ore is arsenic-containing sulfide ore gold ore.

[0057] Take 500g of the above-mentioned refractory gold concentrate and put it into a porcelain bowl, roast it in a muffle furnace at 650°C for 2 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com