A kind of low voc environment-friendly concrete interface treatment agent and preparation method thereof

A technology of environmental protection concrete and interface treatment agent, which is applied in the field of interface agent, can solve problems such as difficult to meet people's environmental protection needs, strict environmental protection standards, and unsatisfaction, and achieve the effect of abundant quantity, high volatility and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

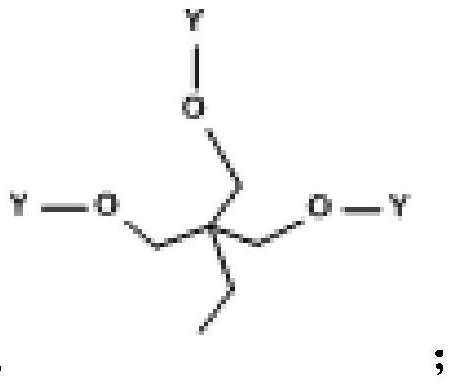

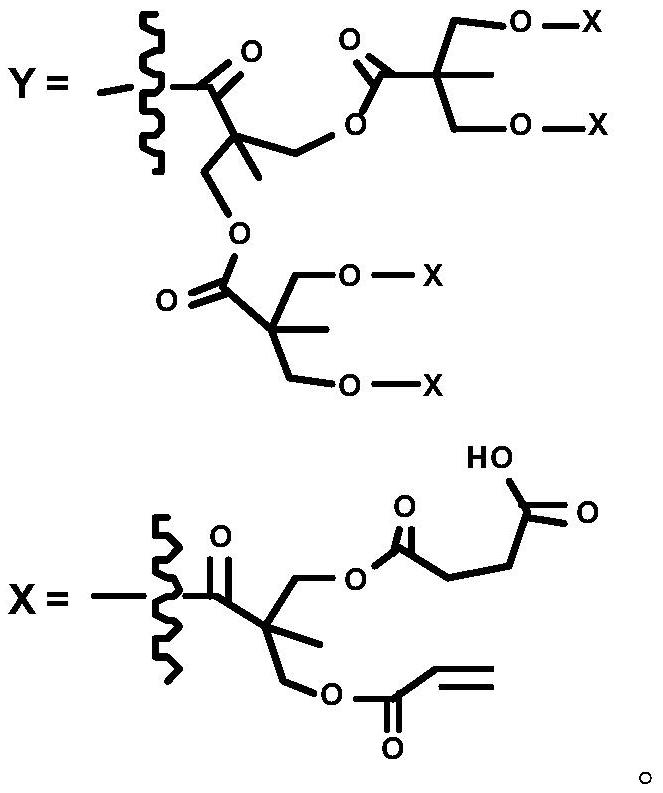

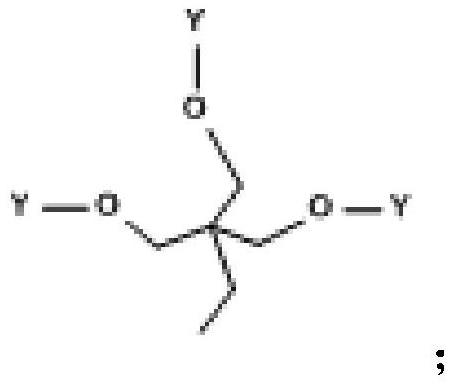

[0052] (1) Preparation of terminal vinyl and carboxyl hyperbranched polyester:

[0053] Add 33.3 grams of trimethylolpropane into the reactor, raise the temperature to 140°C, add dimethylol propionic acid in three steps, first add 100 grams of dimethylol propionic acid, mix well and then add 0.7 grams of p-toluenesulfonate Acid, stir under reduced pressure and react until no bubbles are produced, add 200 grams of dimethylol propionic acid, mix well and then stir under reduced pressure until no bubbles are produced, add 400 grams of dimethylol propionic acid, mix well and reduce Stir under pressure until no bubbles are produced, add 700 grams of N,N-dimethylformamide, after the solid intermediate product dissolves, add 49.7 grams of succinic anhydride, react at 80°C for 12 hours, then add 178.9 grams of acrylic acid, and then add 178.9 grams of acrylic acid at 80°C React for 6 hours, after cooling down to room temperature, wash with water until the product is neutral, put it in...

Embodiment 2

[0057] First add 8kg of water into the dissolution kettle, add 0.3kg of polyvinyl alcohol into the dissolution kettle under stirring to dissolve, then send the dissolved polyvinyl alcohol aqueous solution into the polymerization kettle, add 20g of emulsifier and stir evenly, then heat up to 70°C, Evenly drip 20g ammonium persulfate and 1.41kg vinyl acetate to polymerization kettle, dropwise reaction time is 6 hours, after adding the sepiolite of 10g graft end vinyl and carboxyl hyperbranched polyester, continue reaction 2 hours, After adding 15g of sodium bicarbonate, cool down to 50°C, add 10g of polyethyleneimine and 10g of trimethylolpropane-tris(3-aziridinyl propionate), react for 2 hours, then add 0.2kg of plasticizer And 10g preservative, discharge after being down to room temperature, promptly obtain interface treating agent, described emulsifying agent is alkoxy polyethylene hydroxide ethanol, and described plasticizer is diethylene glycol dibenzoate, described The pre...

Embodiment 3

[0060] First add 8kg of water into the dissolution kettle, add 0.3kg of polyvinyl alcohol into the dissolution kettle under stirring to dissolve, then send the dissolved polyvinyl alcohol aqueous solution into the polymerization kettle, add 20g of emulsifier and stir evenly, then heat up to 70°C, Evenly drip 20g ammonium persulfate and 1.41kg vinyl acetate to polymerization kettle, dropwise reaction time is 6 hours, after adding the sepiolite of 20g graft end vinyl and carboxyl hyperbranched polyester, continue reaction 2 hours, After adding 15g of sodium bicarbonate, cool down to 50°C, add 20g of polyethyleneimine and 20g of trimethylolpropane-tris(3-aziridinyl propionate), react for 2 hours, then add 0.2kg of plasticizer And 10g preservative, discharge after being down to room temperature, promptly obtain interface treating agent, described emulsifying agent is alkoxy polyethylene hydroxide ethanol, and described plasticizer is diethylene glycol dibenzoate, described The pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com