ZnS/ZnO core-shell structure and preparation method and application thereof

A technology of core-shell structure and solvothermal method, which is applied in the field of nanocomposite materials, can solve the problems of low catalytic efficiency of photocatalysts, solve the serious recombination of photogenerated electrons and holes, and stabilize the chemical structure and performance of products, theoretically and practically. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The embodiment of the present invention provides a method for preparing a ZnS / ZnO core-shell structure, the specific steps are as follows:

[0041] (1) Prepare ZnS(en) by solvothermal method 0.5 Precursor, specifically, zinc powder is used as the zinc source, sulfur powder is used as the sulfur source, and ethylenediamine is used as the solvent. The molar ratio of zinc powder and sulfur powder is controlled to be 1:2, and the filling degree of the reactor is controlled to be 60%. Solvothermal method reacted at 180°C for 24h;

[0042] (2) Weigh 0.12g of ZnS(en) 0.5The precursor was placed in a tube furnace, and in an air atmosphere, the temperature was raised from room temperature to 500 °C at a rate of 10 °C / min, then kept at this temperature for 1 h, and finally cooled down to room temperature naturally.

Embodiment 2

[0044] The embodiment of the present invention provides a method for preparing a ZnS / ZnO core-shell structure, the specific steps are as follows:

[0045] (1) Prepare ZnS(en) by solvothermal method 0.5 Precursor, specifically, zinc powder is used as the zinc source, sulfur powder is used as the sulfur source, and ethylenediamine is used as the solvent. The molar ratio of zinc powder and sulfur powder is controlled to be 1:2, and the filling degree of the reactor is controlled to be 60%. Solvothermal method reacted at 180°C for 24h;

[0046] (2) Weigh 0.12g of ZnS(en) 0.5 The precursor was placed in a tube furnace, and in an air atmosphere, the temperature was raised from room temperature to 500 °C at a rate of 10 °C / min, then kept at this temperature for 4 h, and finally cooled down to room temperature naturally.

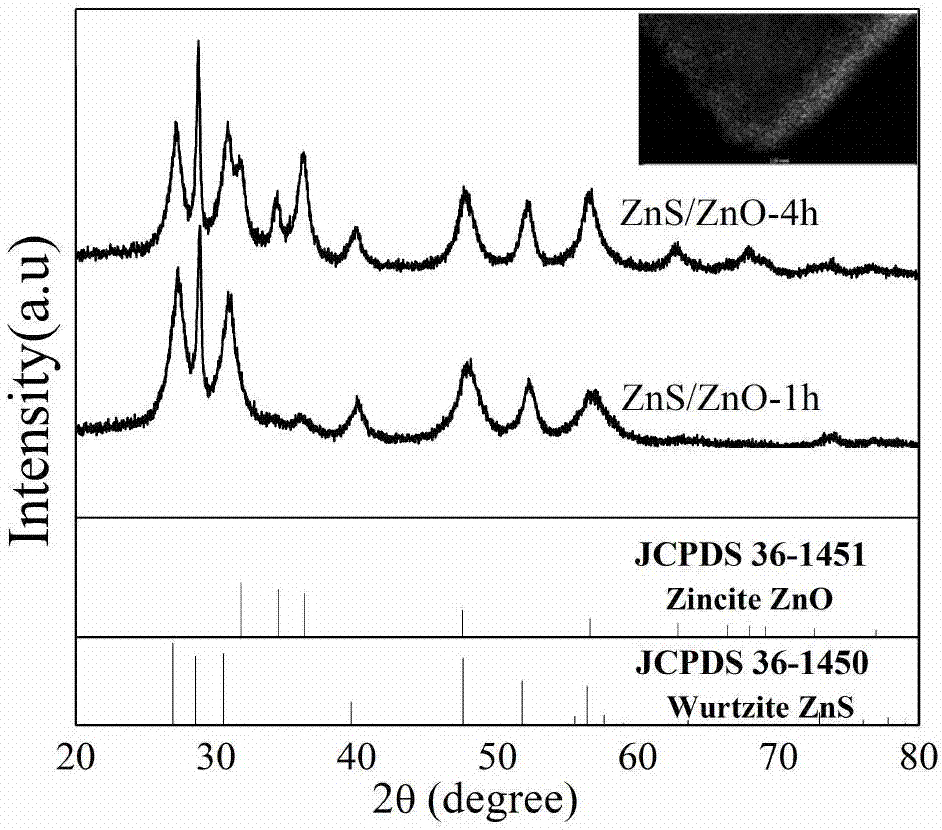

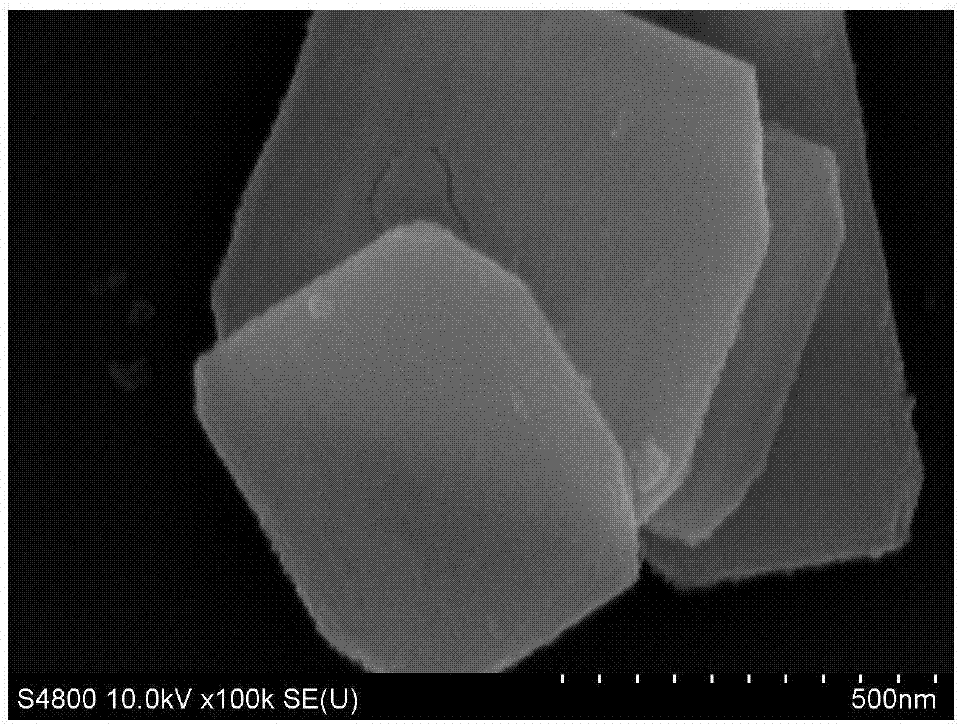

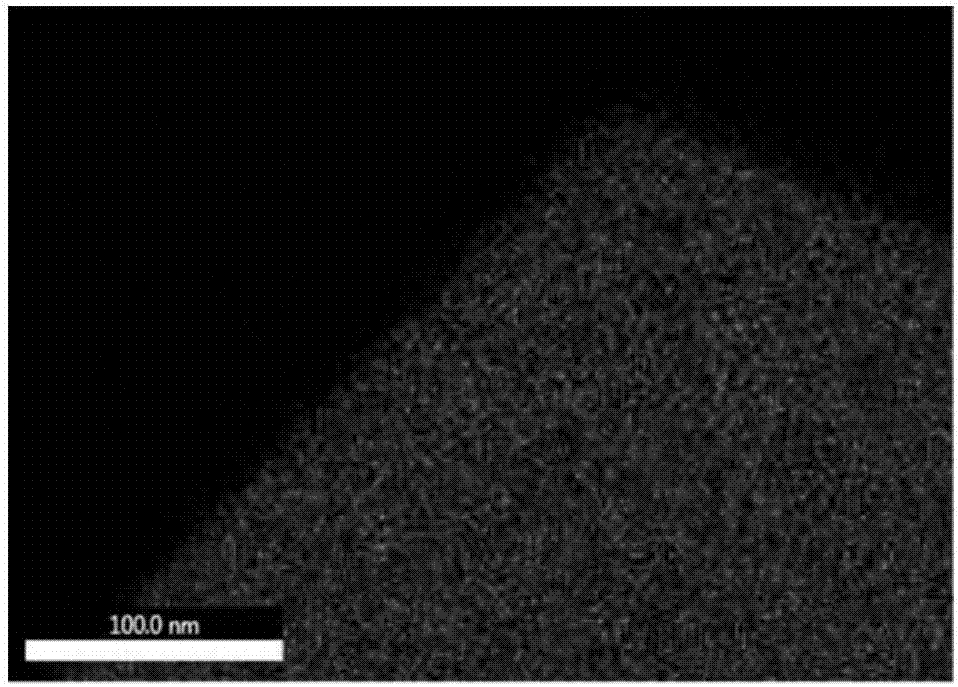

[0047] figure 1 Shown is the X-ray diffraction figure of the prepared ZnS / ZnO core-shell structure in embodiment 1 and embodiment 2, figure 1 The upper right co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com