Kyanite-based reinforced ultralight foam ceramic containing titanium dioxide coating and preparation method thereof

A technology of foam ceramics and titanium dioxide, which is applied in the field of foam ceramic materials, can solve the problems of poor stability of ceramic foam, weaken the strength and stability of foam ceramics, and achieve low production costs, shorten drying time, and improve drying performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

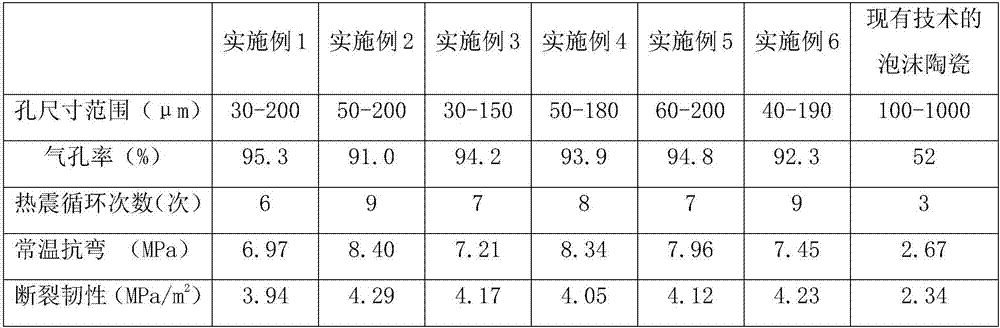

Examples

Embodiment 1

[0027] (1) Kyanite powder with a particle size of 1μm is added to deionized water to make 15% ceramic slurry, according to the ceramic slurry, anorthite, carbon fiber, ceramic powder hydrophobic modifier and polyvinyl alcohol The mass ratio is 100:20:2:0.06:1.2, adding anorthite as a sintering aid, ball milling and dispersing for 5 hours, adding carbon fiber, sodium lauryl sulfate and polyvinyl alcohol, adjusting the slurry pH to 4.5, and using 1500r / min speed rapid shearing and stirring for 10 minutes to foam to obtain particle stable foam.

[0028] (2) Immediately freeze the particle-stabilized foam at -10°C for 12h, then thaw it at 0°C for 3h, repeat the freezing and thawing process once to obtain a foamed ceramic body, and heat it up to 1400 at a rate of 4°C / min ℃, sintering for 2h, after cooling to obtain foam ceramics.

[0029] (3) Completely immerse the ceramic foam in 2mol / L hydrochloric acid, oscillate at 95°C at low speed, take it out, rinse and dry to obtain the acid-p...

Embodiment 2

[0032] (1) Kyanite powder with a particle size of 1.5μm is added to deionized water to make 60% ceramic slurry, according to ceramic slurry, anorthite, carbon fiber, ceramic powder hydrophobization modifier and polyvinyl alcohol The mass ratio is 100:30:5:0.08:1.5, adding anorthite as a sintering aid, ball milling and dispersing for 5 hours, adding carbon fiber, cetyl ammonium chloride and polyvinyl alcohol, adjusting the slurry pH to 6.5, Quickly shear for 10 minutes at a speed of 2500r / min and stir and foam to obtain a stable particle foam.

[0033] (2) Immediately freeze the particle-stabilized foam at -10°C for 24h, then thaw it at 10°C for 12h, repeat the freezing and thawing process 5 times to obtain a foamed ceramic body, and heat it up to 1900 at a rate of 5°C / min ℃, sintering for 3h, and cooling to obtain foam ceramics.

[0034] (3) Completely immerse the ceramic foam in 2mol / L hydrochloric acid, oscillate at a low speed at 100°C, take it out, rinse and dry to obtain the ...

Embodiment 3

[0037] (1) Kyanite powder with a particle size of 1.2μm is added to deionized water to make 45% ceramic slurry, according to ceramic slurry, anorthite, carbon fiber, ceramic powder hydrophobization modifier and polyvinyl alcohol The mass ratio is 100:25:3:0.07:1.3, adding anorthite as a sintering aid, ball milling and dispersing for 5 hours, adding carbon fiber, sodium cetyl sulfate and polyvinyl alcohol, adjusting the slurry pH to 5, 1600r / min speed rapid shearing and stirring for 10min foaming to obtain particle stable foam.

[0038] (2) Immediately freeze the particle-stabilized foam at -10°C for 18h, then thaw it at 5°C for 6h, repeat the freezing and thawing process three times to obtain a foam ceramic body, and heat it up to 1600 at a rate of 4.2°C / min ℃, sintering for 2h, after cooling to obtain foam ceramics.

[0039] (3) Completely immerse the ceramic foam in 2mol / L hydrochloric acid, oscillate at a low speed at 98°C, take it out, rinse and dry to obtain the acid-pretreat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com