Preparing method of hollow magnetic carbon nanospheres with MOFs growing inside in confinement mode

A technology of magnetic carbon and nanospheres, applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of small size, non-magnetic MOFs, poor stability, etc., to improve catalytic performance and morphology. Uniform and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

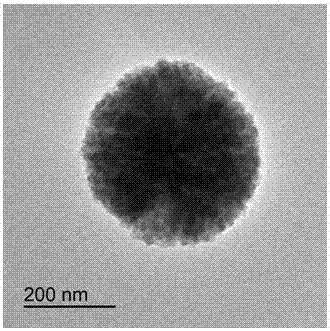

[0042] 1. Preparation of magnetic carbon nanocages:

[0043] 3.6 g FeCl 3 ·6H 2 O, 90 ml of ethylene glycol, 10 ml of ethanol and 2.4 g of sodium acetate were mixed, mechanically stirred at room temperature for 30 min, the mixed solution was transferred to a reactor, and hydrothermally reacted at 200 °C for 10 h. After the reaction was completed, it was washed by centrifugation and dried to obtain 200 nm Fe 3 o 4 ball.

[0044] Mix 75 ml of ethanol, 30 ml of deionized water and 3 ml of ammonia water, and mix 0.3 g Fe 3 o 4 The spheres were dispersed into the mixed solution; 0.6 g tetraethylorthosilicate (TEOS) was added dropwise at a constant speed to the 3 o 4 In the mixed solution, stir mechanically at room temperature and react for 10 min to form a core-shell structure of Fe 3 o 4 @SiO 2 nanospheres.

[0045] 1 ml of formaldehyde solution and 0.5 g of resorcinol were added to the above reaction system, and the reaction was carried out under mechanical stirring fo...

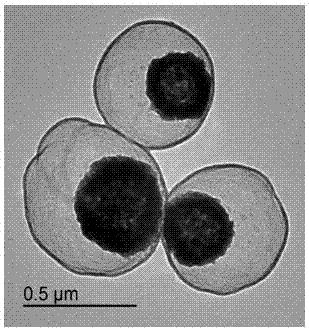

Embodiment 2

[0054] 1. Preparation of magnetic carbon nanocages:

[0055] 3.6 g FeCl 3 ·6H 2 O, 90 ml of ethylene glycol, 10 ml of ethanol and 2.4 g of sodium acetate were mixed, mechanically stirred at room temperature for 30 min, the mixed solution was transferred to a reactor, and hydrothermally reacted at 200 °C for 10 h. After the reaction was completed, it was washed by centrifugation and dried to obtain 200 nm Fe 3 o 4 ball.

[0056] Mix 75 ml of ethanol, 30 ml of deionized water and 3 ml of ammonia water, and mix 0.3 g Fe 3 o 4 The spheres were dispersed into the mixed solution; 0.6 g tetraethylorthosilicate (TEOS) was added dropwise at a constant speed to the 3 o 4In the mixed solution, stir mechanically at room temperature and react for 10 min to form a core-shell structure of Fe 3 o 4 @SiO 2 nanospheres.

[0057] 1 ml of formaldehyde solution and 0.5 g of resorcinol were added to the above reaction system, and the reaction was carried out under mechanical stirring for...

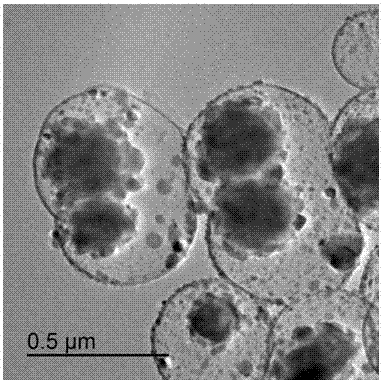

Embodiment 3

[0066] 1. Preparation of magnetic carbon nanocages:

[0067] 3.6 g FeCl 3 ·6H 2 O, 90 ml of ethylene glycol, 10 ml of ethanol and 2.4 g of sodium acetate were mixed, mechanically stirred at room temperature for 30 min, the mixed solution was transferred to a reactor, and hydrothermally reacted at 200 °C for 10 h. After the reaction was completed, it was washed by centrifugation and dried to obtain 200 nm Fe 3 o 4 ball.

[0068] Mix 75 ml of ethanol, 30 ml of deionized water and 3 ml of ammonia water, and mix 0.3 g Fe 3 o 4 The spheres were dispersed into the mixed solution; 0.6 g tetraethylorthosilicate (TEOS) was added dropwise at a constant speed to the 3 o 4 In the mixed solution, stir mechanically at room temperature and react for 10 min to form a core-shell structure of Fe 3 o 4 @SiO 2 nanospheres.

[0069] 1 ml of formaldehyde solution and 0.5 g of resorcinol were added to the above reaction system, and the reaction was carried out under mechanical stirring fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com