Application and preparation method of zeolite molecular sieve

A zeolite molecular sieve and molecular sieve technology, applied in separation methods, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of high loss, high equipment corrosion rate of corrosive amine solution, difficulty in obtaining high purity, etc. selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of zeolite molecular sieve, comprising the steps of:

[0034] 1-1) Heat a mixture of 40mL of distilled water, 14g of potassium hydroxide and 8g of aluminum hydroxide until the solution becomes clear and transparent (keep the amount of distilled water at 40mL), cool at room temperature for later use to obtain potassium metaaluminate solution.

[0035] 1-2) Mix potassium metaaluminate solution and CsOH solution, then add silica sol, stir for 10 minutes until the mixture solution is uniform, and the molar ratio of raw materials is 2.4K 2 O:0.06Cs 2 O:4.0SiO 2 : Al 2 o 3 :36H 2 O.

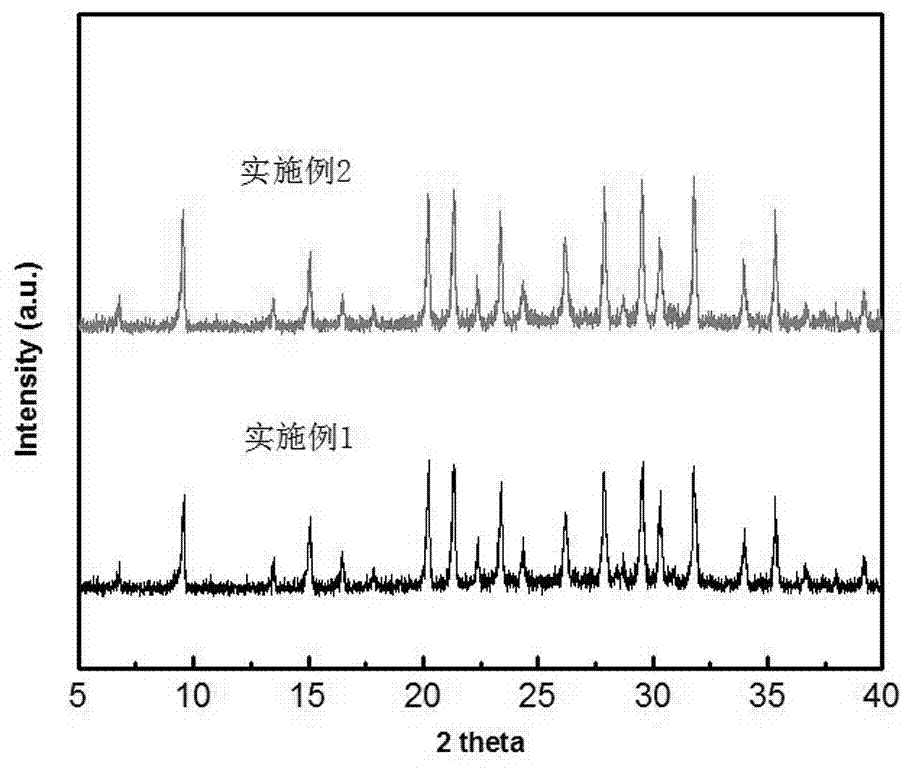

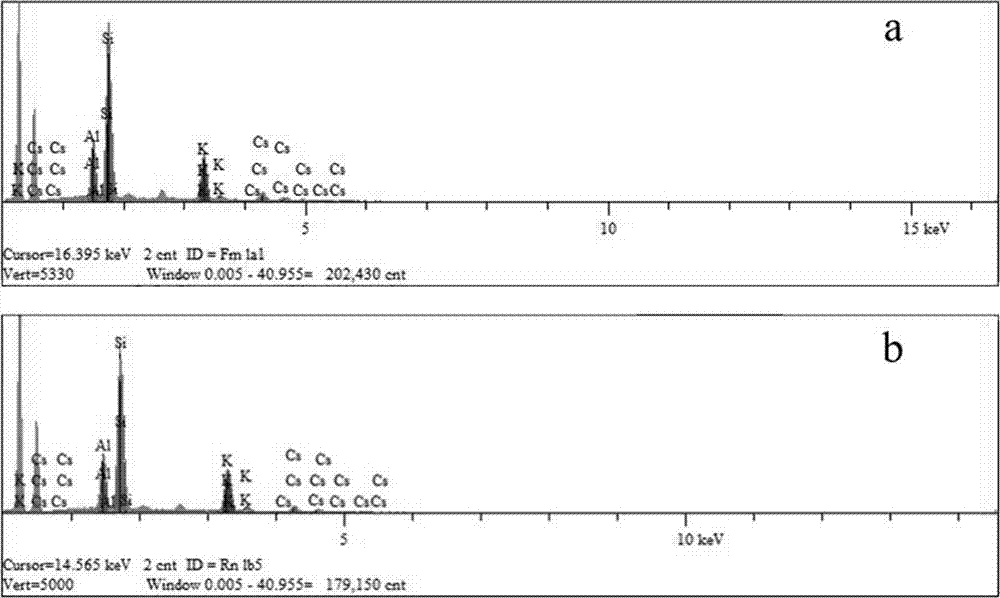

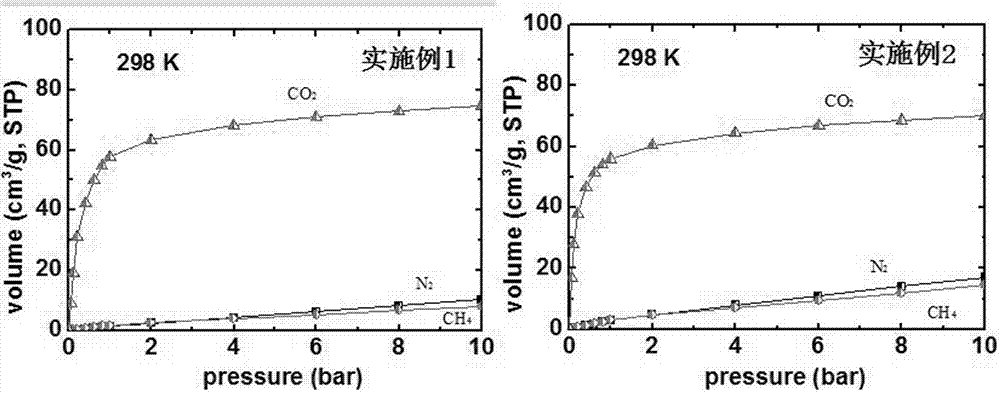

[0036] 1-3) Then transfer the mixture into a 23mL polytetrafluoroethylene-lined autoclave, and react at 423K for 4 days. After the crystallization is completed, wash with distilled water, filter, and dry at 373K to obtain a white powder. The obtained sample was characterized by XRD to obtain ZK-5. The silicon-aluminum ratio was measured to be 3.21 by elemental analysi...

Embodiment 2

[0039] A preparation method of zeolite molecular sieve, comprising the steps of:

[0040] 1-1) Heat a mixture of 40mL of distilled water, 14g of potassium hydroxide and 8g of aluminum hydroxide until the solution becomes clear and transparent (keep the amount of distilled water at 40mL), cool at room temperature for later use to obtain potassium metaaluminate solution.

[0041] 1-2) Mix potassium metaaluminate solution and CsOH solution, then add silica sol, stir for 10 minutes until the mixture solution is uniform, and the molar ratio of raw materials is 2.4K 2 O:0.06Cs 2 O:4.26SiO 2 : Al 2 o 3 :36H 2 O.

[0042] 1-3) Then transfer the mixture into a 23mL polytetrafluoroethylene-lined autoclave, and react at 423K for 4 days. After the crystallization is completed, wash with distilled water, filter, and dry at 373K to obtain a white powder. The obtained sample was characterized by XRD to obtain ZK-5. The silicon-aluminum ratio was measured to be 3.30 by elemental analys...

Embodiment 3

[0048] A preparation method of zeolite molecular sieve, comprising the steps of:

[0049] 1-1) Heat a mixture of 40mL of distilled water, 14g of potassium hydroxide and 8g of aluminum hydroxide until the solution becomes clear and transparent (keep the amount of distilled water at 40mL), cool at room temperature for later use to obtain potassium metaaluminate solution.

[0050] 1-2) Mix potassium metaaluminate solution and CsOH solution, then add silica sol, stir for 10 minutes until the mixture solution is uniform, and the molar ratio of raw materials is 2.4K 2 O:0.06Cs 2 O:4.1SiO 2 : Al 2 o 3 :36H 2 O.

[0051] 1-3) Then transfer the mixture into a 23mL polytetrafluoroethylene-lined autoclave, and react at 423K for 4 days. After the crystallization is completed, wash with distilled water, filter, and dry at 373K to obtain a white powder. The obtained sample was characterized by XRD to obtain ZK-5. The silicon-aluminum ratio was measured to be 3.24 by elemental analysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com