Asymmetric sodium benzenesulfonate Gemini surfactant and preparation method thereof

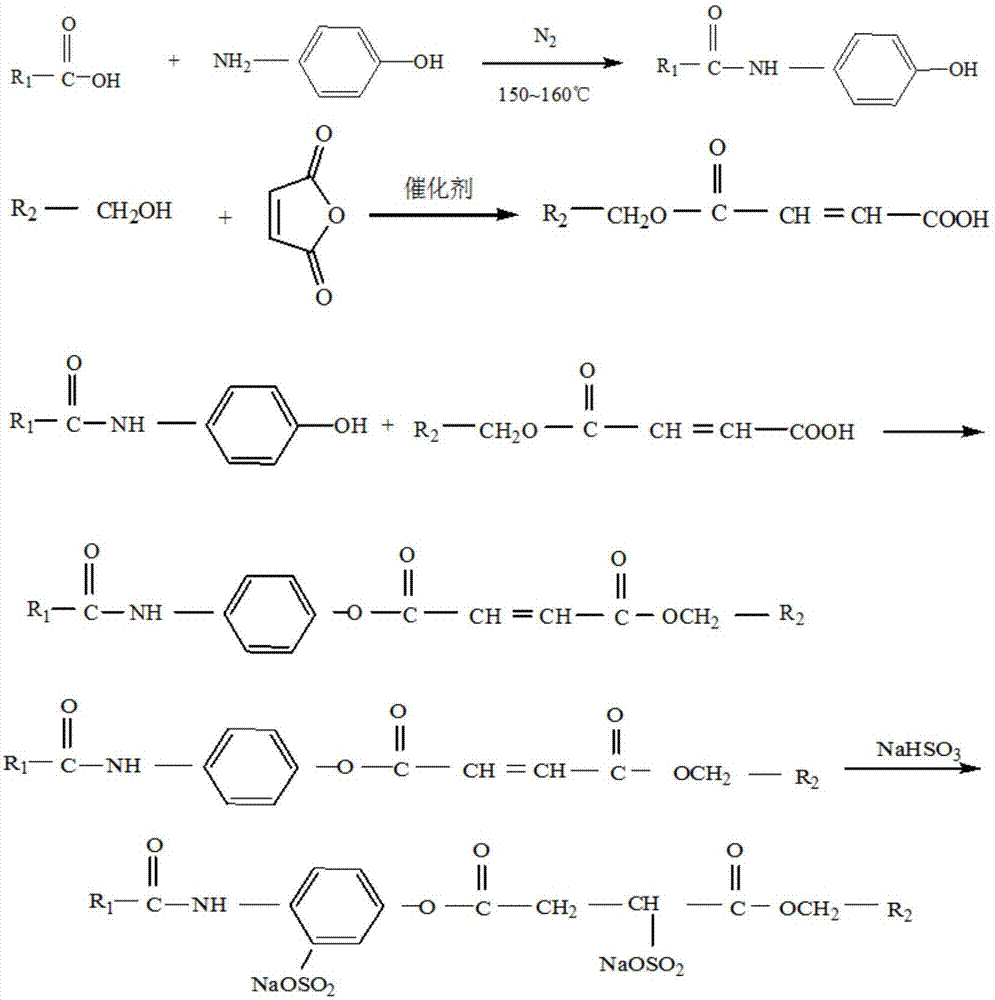

A technology of surfactant and sodium benzenesulfonate, which is applied in the preparation of sulfonate, carboxylate and carboxamide, etc. It can solve the complex synthesis and purification separation process, difficulty in large-scale production, and cumbersome synthesis route and other problems, to achieve the effect of low critical micelle concentration, low price and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

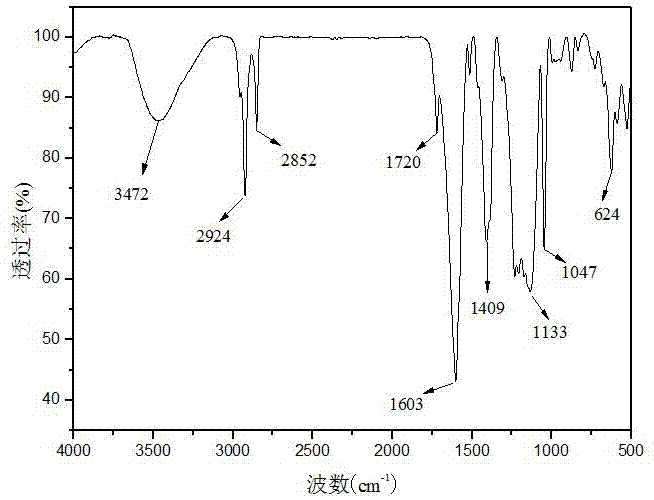

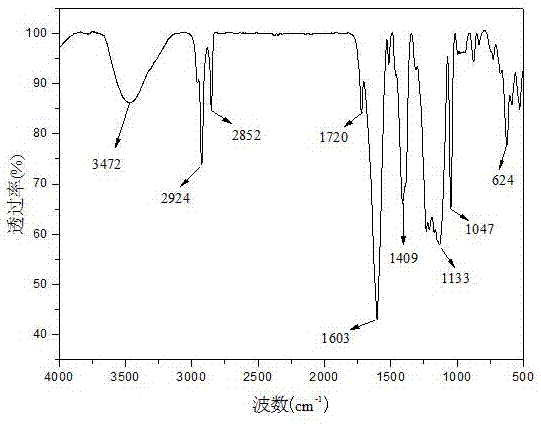

Image

Examples

Embodiment 1

[0034]Step 1: get 20.1 parts by weight of dodecanoic acid, the p-aminophenol of 11.5 parts by weight, add 0.5% ethyl acetate of dodecanoic acid and the total mass of p-aminophenol as a catalyst, 1% of the total mass of dodecanoic acid and p-aminophenol 0.4% mixture of sodium bisulfite and sodium borohydride (mixing ratio m (sodium bisulfite): m (sodium borohydride) = 3:2) as an antioxidant, dimethyl sulfoxide as a solvent to dissolve p-amino Phenol was added into a 250mL hydrothermal kettle, and the hydrothermal kettle was put into an oven for reaction. The temperature was raised to 160° C., and the reaction was carried out for 5 hours to obtain the crude product 4-(dodecylamide)phenol. Mix and extract the crude product with ethyl acetate and distilled water; then rotary evaporate, dry and recrystallize to obtain the purified product.

[0035] Step 2: get the dodecyl alcohol of 18.6 weight parts, the maleic anhydride of 9.8 weight parts, join in the 250mL four-necked flask, ad...

Embodiment 2

[0038] Embodiment 2: the surface performance measurement of unsymmetrical benzenesulfonic acid sodium salt Gemini surfactant

[0039] The reduction of surface tension of water by surfactant is an important parameter to evaluate its surface activity. In this study, the surface tension of a series of surfactant solutions with different concentrations was measured by the method of pulling up the liquid film with a ring, and the curve of the surface tension changing with the concentration was drawn, and the data was read from the inflection point of the curve. The concentration at this time is the critical micelle concentration , the corresponding surface tension is the surface tension corresponding to the critical micelle concentration (γ cmc ).

[0040] Depend on figure 1 It can be seen that with the increase of surfactant concentration, the surface tension of benzenesulfonic acid sodium salt Gemini surfactant gradually decreases, and its critical micelle concentration is 0.80...

Embodiment 3

[0041] Embodiment 3: the emulsification performance measurement of unsymmetrical benzene sulfonic acid sodium salt Gemini surfactant

[0042] In this study, the emulsifying ability of modified rapeseed oil was tested by water separation time method. It can be seen from Table 1 that the emulsification time of benzenesulfonic acid sodium salt Gemini surfactant to modified rapeseed oil is 283s, compared with traditional dodecylbenzenesulfonic acid sodium salt, benzenesulfonic acid sodium salt Gemini surfactant The emulsifying property is better, and it has a good emulsifying effect on oil.

[0043] The emulsifying power measurement result of table 1 besylate type Gemini surfactant

[0044] Surfactant type

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical micelle concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com