Method for manufacturing metallic vanadium

A manufacturing method and metal technology, applied in the field of metal vanadium, can solve the problems of large-scale equipment, difficult treatment of vanadium halides, and failure to achieve practical use, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Next, examples will be described.

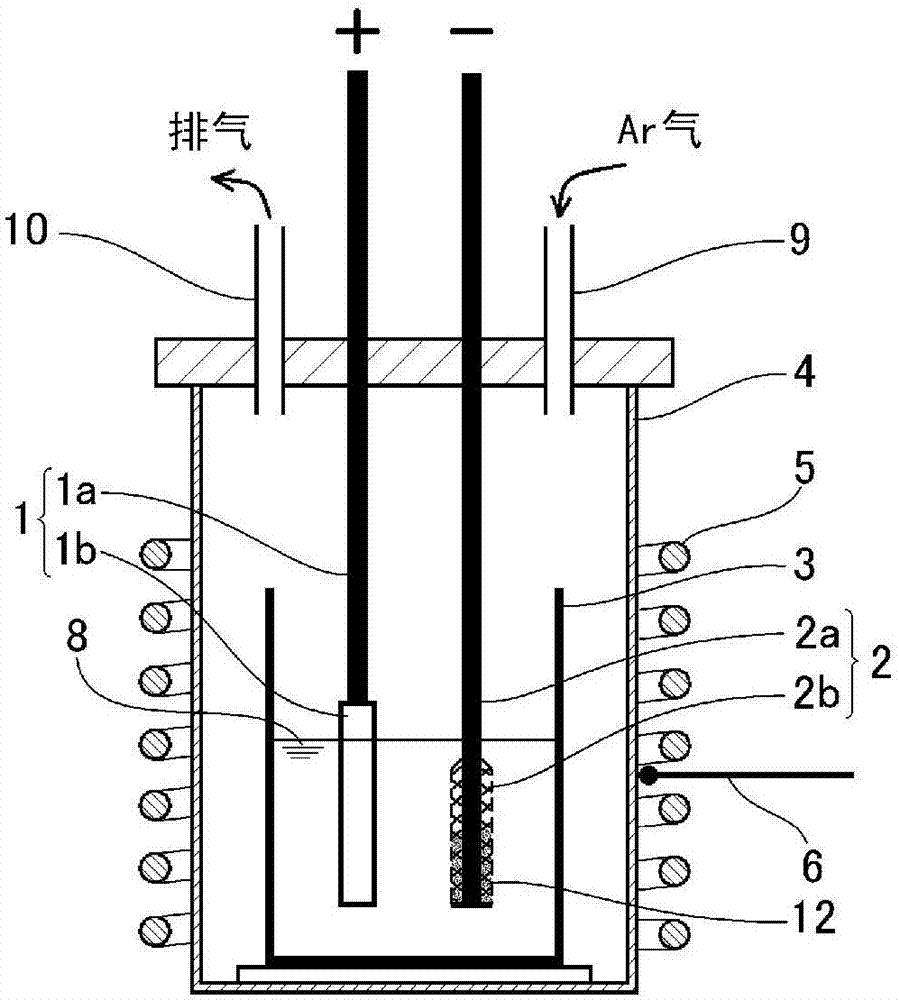

[0093] In this embodiment, as the molten salt (mixed molten salt) 8, 600 g of calcium chloride (manufactured by Wako Pure Chemical Industries, Ltd., reagent special grade) is obtained by adding 0.5 mol% calcium sulfide (manufactured by Wako Pure Chemical Industries, Ltd., special grade reagent) Put the substance in the crucible 3 (with an inner diameter of 90mm and a depth of 200mm). The crucible 3 was placed in a closed container 4 (inner diameter of 105 mm, depth of 480 mm), flanges were attached and sealed, and after vacuum dehydration treatment, the temperature was raised to 900° C. in an argon atmosphere.

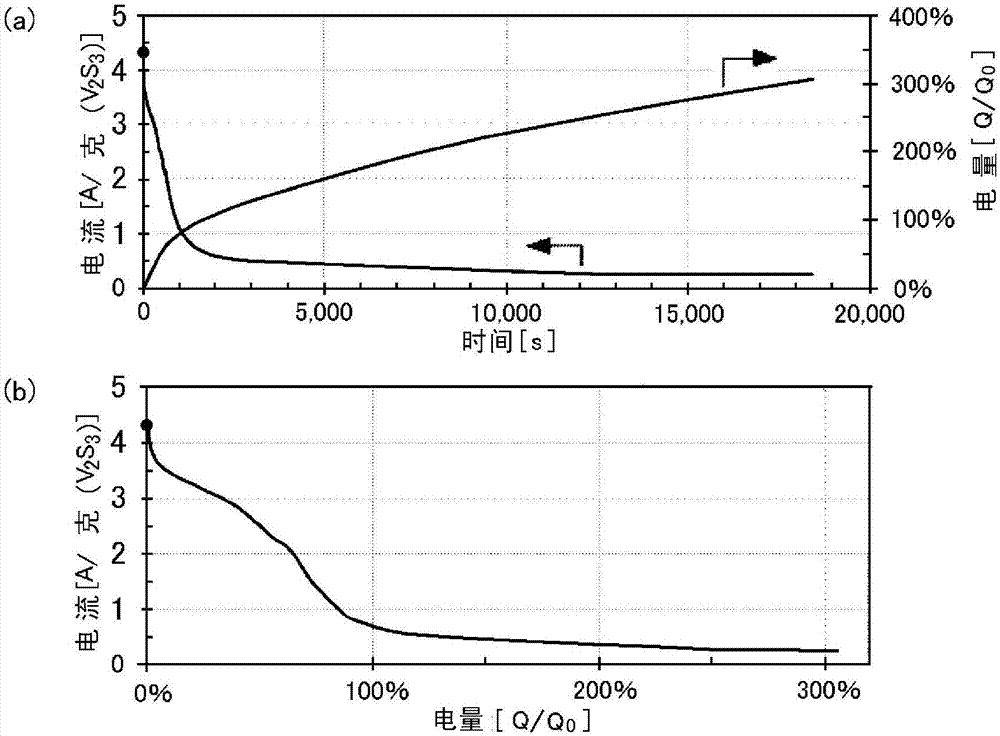

[0094] In addition, the titanium rod 1a and the carbon rod 1b of the anode 1 and the titanium rod 2a of the cathode 2 and the container 2b installed so as to surround the titanium rod are prepared. 1.502 g of vanadium sulfide 12 (purity 99% manufactured by Yauchi Chemical Co., Ltd.) was inserted into the container 2b.

[0095] Afte...

Embodiment 2

[0098] In this embodiment, as molten salt 8, a substance obtained by adding 0.5 mol% calcium sulfide (made by Wako Pure Chemical Industries, Ltd., special grade reagent) to 600 g of calcium chloride (made by Wako Pure Chemical Industries, Ltd., special grade reagent) is placed in a crucible 3 (Inner diameter is 90mm, depth is 200mm). The crucible 3 was placed in a closed container 4 (inner diameter of 105 mm, depth of 480 mm) and flanges were attached to seal the crucible 3, and after vacuum dehydration treatment, the temperature was raised to 900°C in an argon atmosphere.

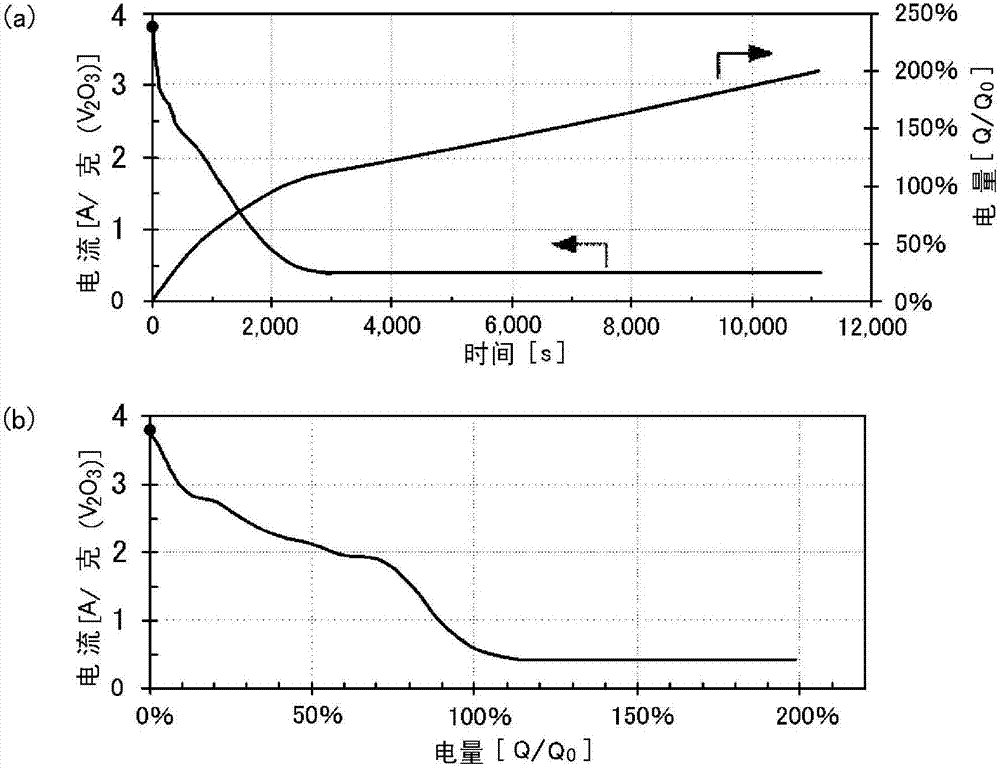

[0099] In addition, the titanium rod 1a and the carbon rod 1b of the anode 1 and the titanium rod 2a of the cathode 2 and the container 2b installed so as to surround the titanium rod are prepared. In the container 2b, 1.488 g of vanadium trioxide 12 (purity of 99% or more manufactured by Sun Miner) is inserted.

[0100] After the temperature has stabilized, the two electrodes 1 and 2 are inserted into the mol...

Embodiment 3

[0103] In this example, as raw materials (vanadium compound 12), 4 g of ammonium metavanadate (Wako Pure Chemical Special Grade Reagent) and vanadyl sulfate (Xinxing Chemical) were prepared respectively. Then, each prepared raw material was subjected to heat treatment (heating temperature: 600°C, heating time: 10 minutes) as a pretreatment to obtain a treated material. The obtained substances were analyzed, and the results were all vanadium pentoxide oxide (V 2 O 5 ).

[0104] Use each vanadium pentoxide oxide (V 2 O 5 ), respectively, to manufacture metallic vanadium. At this time, put the vanadium oxide (V 2 O 5 The amount of) is 1.500 g in either case. In addition, due to the removal of vanadium oxide (V 2 O 5 The manufacturing conditions other than the amount of) are the same as in Example 2, so the description is omitted here.

[0105] The analysis results of the sulfur content and the oxygen content (oxygen concentration) of the samples (manufactured samples) produced by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com