Near-infrared radiation ceramic coating used for ethylene cracking furnace and preparation method and application of near-infrared radiation ceramic coating

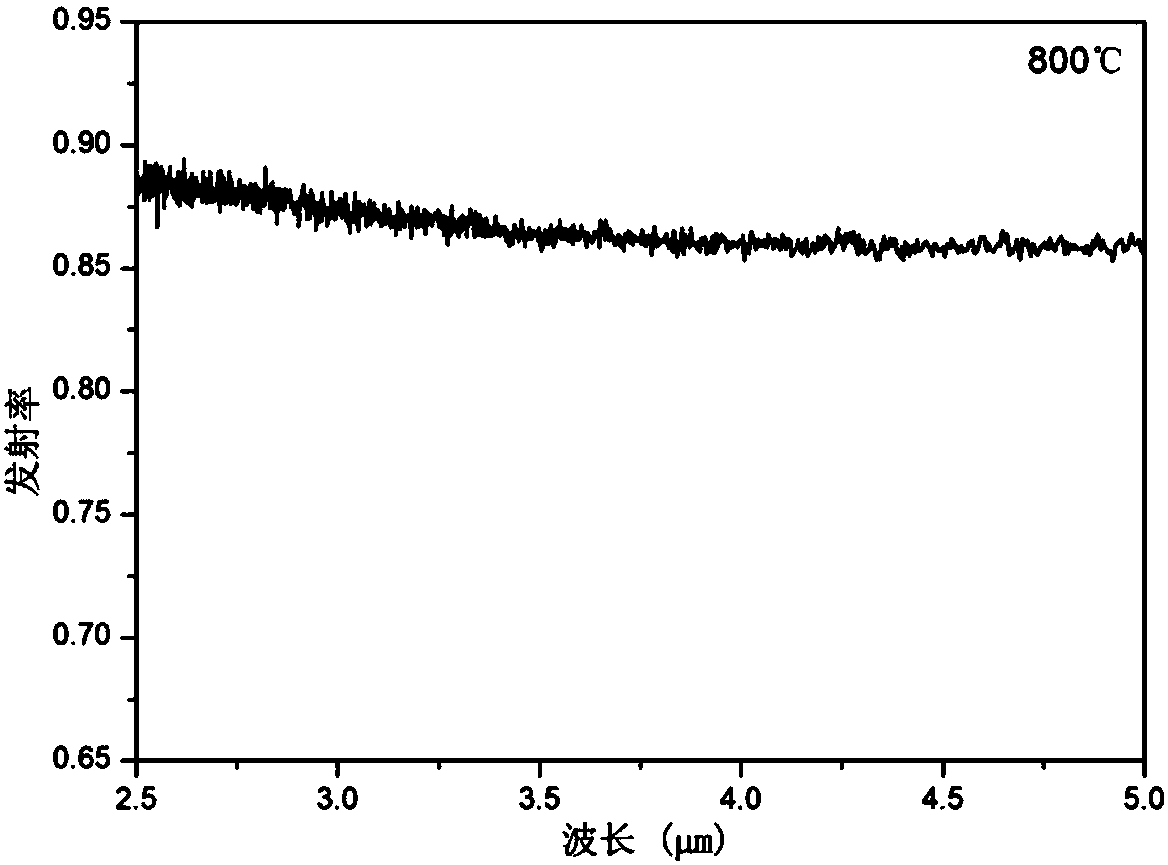

A technology of near-infrared radiation and ethylene cracking furnace, which is applied in the field of near-infrared radiation ceramic coatings and its preparation, can solve the problems of reducing the actual life of coatings, cracking, poor thermal shock resistance, etc., and achieve enhanced radiation energy-saving efficiency and improved combination Strength and the effect of improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of near-infrared radiation ceramic coating for ethylene cracking furnace, composed of component A and component B,

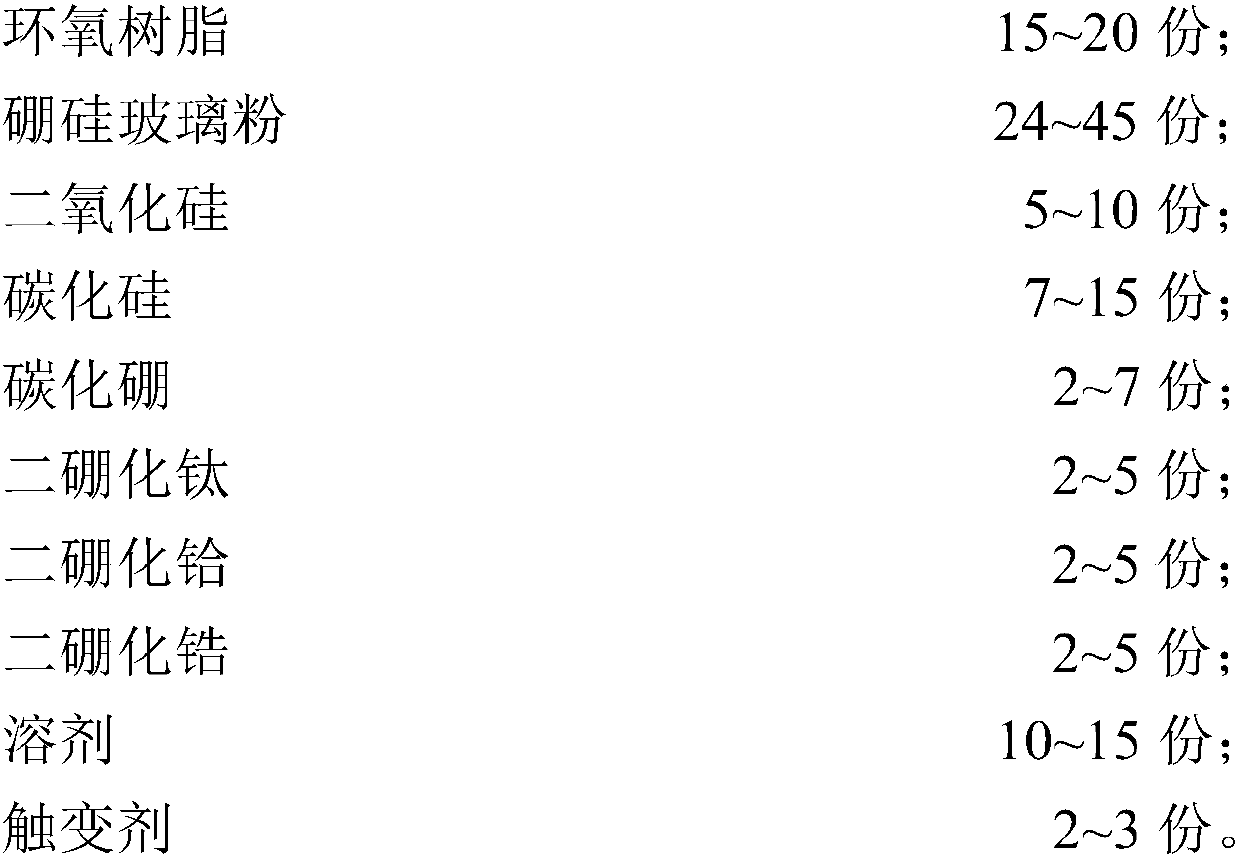

[0047] The parts by weight of component A comprise:

[0048]

[0049] The particle diameters of borosilicate glass powder, silicon carbide, silicon dioxide, boron carbide, titanium diboride, hafnium diboride and zirconium diboride added to the paint are all 325 mesh.

[0050] The weight composition of B component comprises:

[0051] 75 parts of polyamide;

[0052] 25 parts of ethanol.

[0053] Its preparation method comprises the following steps:

[0054] (1) Borosilicate glass powder, silicon carbide, silicon dioxide, boron nitride, boron carbide, titanium boride, hafnium diboride and zirconium diboride powder are ball milled on a vibration mill for 3 hours, The ball-to-material ratio is 3:1; the mixed powder is obtained;

[0055] (2) Epoxy resin, thixotropic agent, solvent are stirred and dispersed in the reactor, and the rotating speed i...

Embodiment 2

[0060] A kind of near-infrared radiation ceramic coating for ethylene cracking furnace, composed of component A and component B,

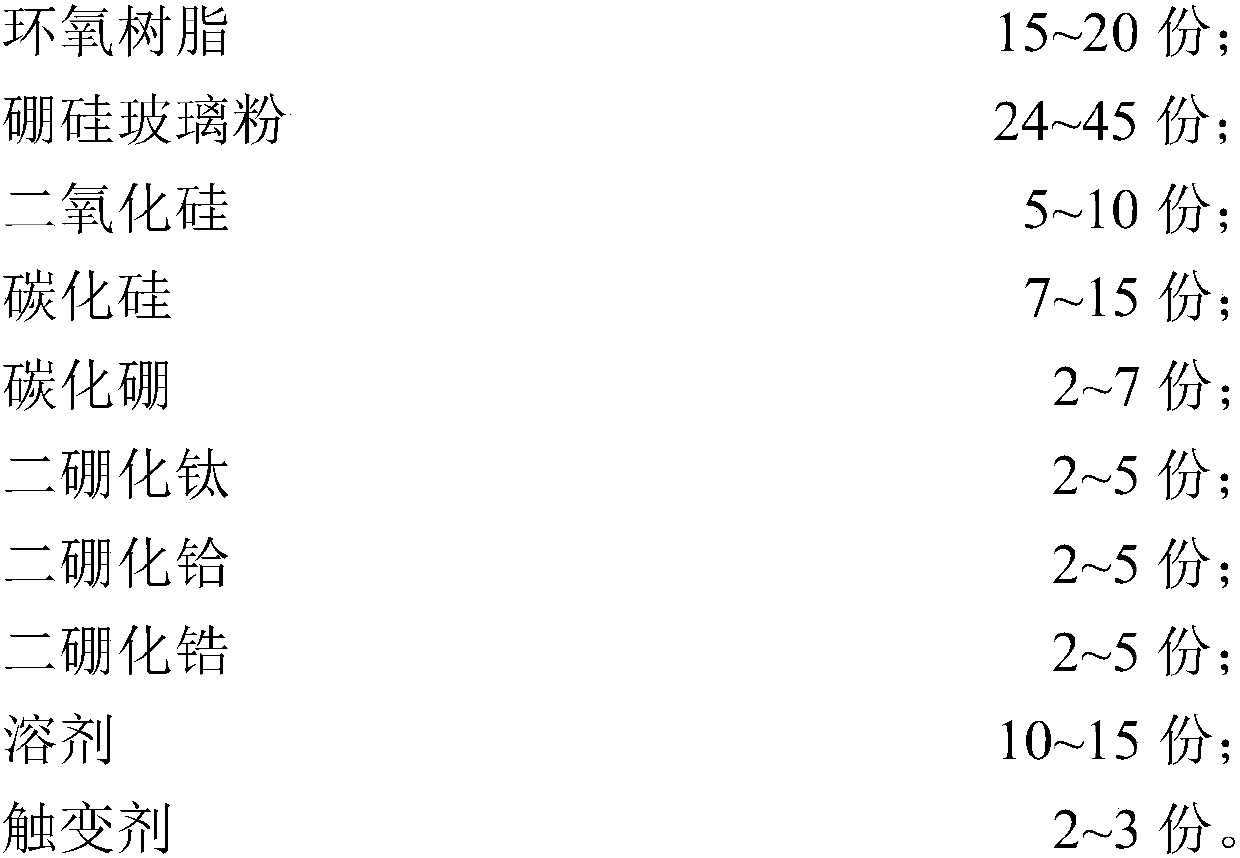

[0061] The parts by weight of component A comprise:

[0062]

[0063] At the same time, the particle size of borosilicate glass powder, silicon carbide, silicon dioxide, boron nitride, boron carbide, titanium boride, hafnium diboride and zirconium diboride added in the coating is 300 mesh.

[0064] The weight composition of B component comprises:

[0065] 85 parts of polyamide;

[0066] 15 parts of ethanol.

[0067] Its preparation method comprises the following steps:

[0068] (1) Borosilicate glass powder, silicon carbide, silicon dioxide, boron nitride, boron carbide, titanium boride, hafnium diboride and zirconium diboride powder are ball milled on a vibration mill for 3 hours, The ball-to-material ratio is 3:1; the mixed powder is obtained;

[0069] (2) Epoxy resin, thixotropic agent, solvent are stirred and dispersed in the reactor, a...

Embodiment 3

[0074] A kind of near-infrared radiation ceramic coating for ethylene cracking furnace, composed of component A and component B,

[0075] The parts by weight of component A comprise:

[0076]

[0077] The particle size of the borosilicate glass powder, silicon carbide, silicon dioxide, boron carbide, titanium diboride, hafnium diboride and zirconium diboride added in the paint is 325 mesh.

[0078] The weight composition of B component comprises:

[0079] 80 parts of phenalkamine;

[0080] 20 parts of ethanol.

[0081] Its preparation method comprises the following steps:

[0082] (1) Borosilicate glass powder, silicon carbide, silicon dioxide, boron nitride, boron carbide, titanium boride, hafnium diboride and zirconium diboride powder are ball milled on a vibration mill for 3 hours, The ball-to-material ratio is 3:1; the mixed powder is obtained;

[0083] (2) Epoxy resin, thixotropic agent, solvent are stirred and dispersed in the reactor, and the rotating speed is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com