A kind of titanium dioxide/seaweed polysaccharide composite nanoparticle and its preparation method and application

A technology of composite nanoparticles and seaweed polysaccharide, applied in cosmetic preparations, cosmetics, pharmaceutical formulations, etc., can solve the problems of strong photochemical catalytic activity, poor weather resistance, easy aggregation, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of titanium dioxide / seaweed polysaccharide composite nanoparticles, comprising the following steps:

[0040] 1) Take 25 parts by weight of sodium alginate, add 3000 parts by weight of water, heat up to 80°C, and stir to completely dissolve the sodium alginate;

[0041] 2) Add 15 parts by weight of nano-titanium dioxide into 100 parts by weight of ethanol to prepare a suspension with a concentration of 15% by weight, then add the above-mentioned sodium alginate solution, mix well, and use 10% citric acid aqueous solution Adjust the pH of the mixture to 4.2, then irradiate with ultraviolet light, stir and react for 2 hours, and control the reaction temperature at 50°C;

[0042] 3) After the reaction is completed, the liquid is filtered off, and the solid is dried at 90° C. for 4 hours to obtain titanium dioxide / seaweed polysaccharide composite nanoparticles.

Embodiment 2

[0044] A preparation method of titanium dioxide / seaweed polysaccharide composite nanoparticles, comprising the following steps:

[0045] 1) Take 20 parts by weight of agar, add 2500 parts by weight of water, heat up to 80°C, and stir to completely dissolve the agar;

[0046] 2) Add 30 parts by weight of nano-titanium dioxide into 200 parts by weight of ethanol to prepare a suspension with a concentration of 15% by weight, then add the above-mentioned agar solution, mix well, and use 2% hydrochloric acid aqueous solution to dissolve the mixed solution The pH of the solution was adjusted to 5.1, and then irradiated with an ultraviolet lamp, stirred and reacted for 3 hours, and the reaction temperature was controlled at 60°C;

[0047] 3) After the reaction is completed, the liquid is filtered off, and the solid is dried at 90° C. for 4 hours to obtain titanium dioxide / seaweed polysaccharide composite nanoparticles.

Embodiment 3

[0049] A preparation method of titanium dioxide / seaweed polysaccharide composite nanoparticles, comprising the following steps:

[0050] 1) Take 15 parts by weight of sodium alginate, add 3500 parts by weight of water, heat up to 80°C, and stir to completely dissolve the sodium alginate;

[0051] 2) Add 40 parts by weight of nano-titanium dioxide into 250 parts by weight of ethanol to prepare a suspension with a concentration of 20% by weight, then add the above-mentioned sodium alginate solution, mix well, and use 20% aqueous acetic acid to dissolve The pH of the mixture was adjusted to 5.5, and then irradiated with an ultraviolet lamp, stirred and reacted for 2.5 hours, and the reaction temperature was controlled at 60°C;

[0052] 3) After the reaction is completed, the liquid is filtered off, and the solid is dried at 90° C. for 4 hours to obtain titanium dioxide / seaweed polysaccharide composite nanoparticles.

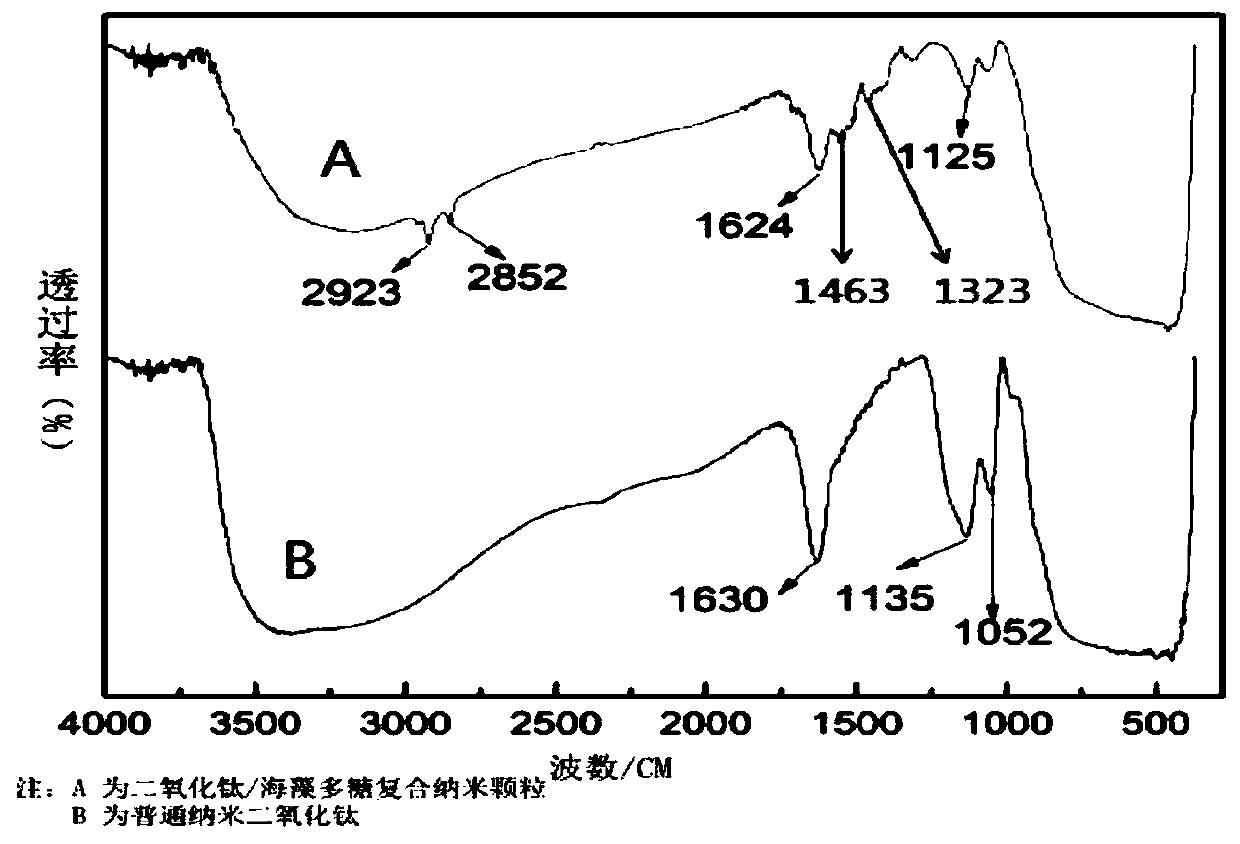

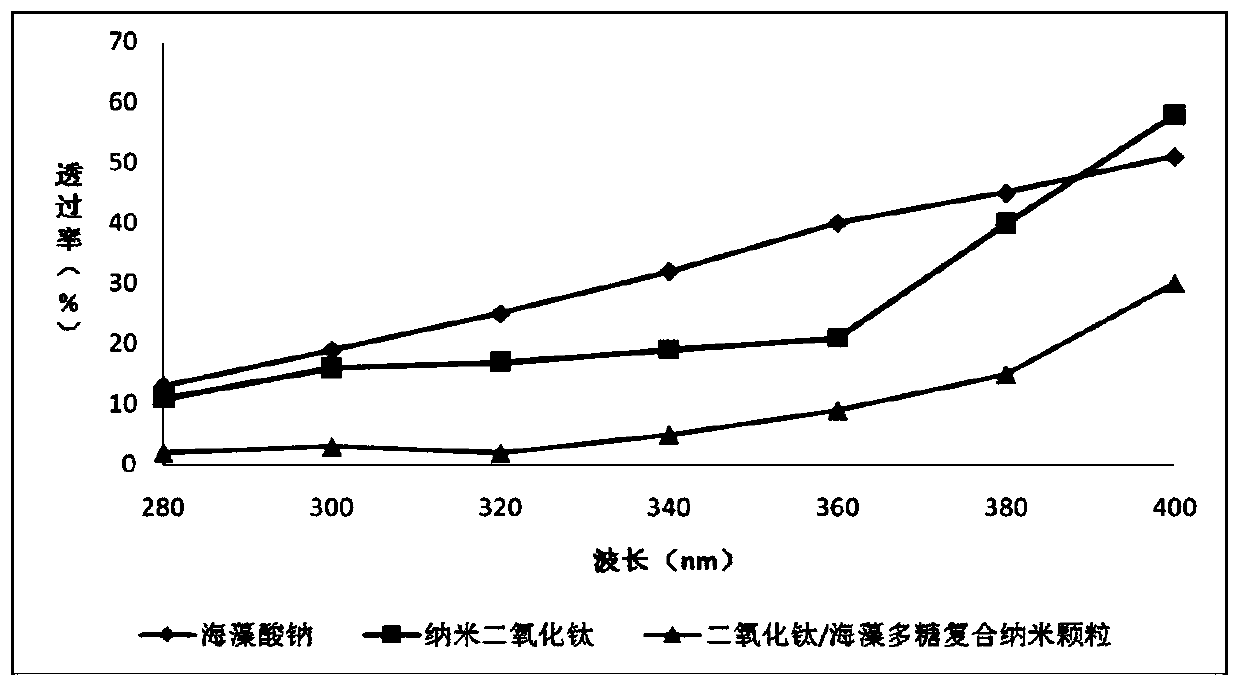

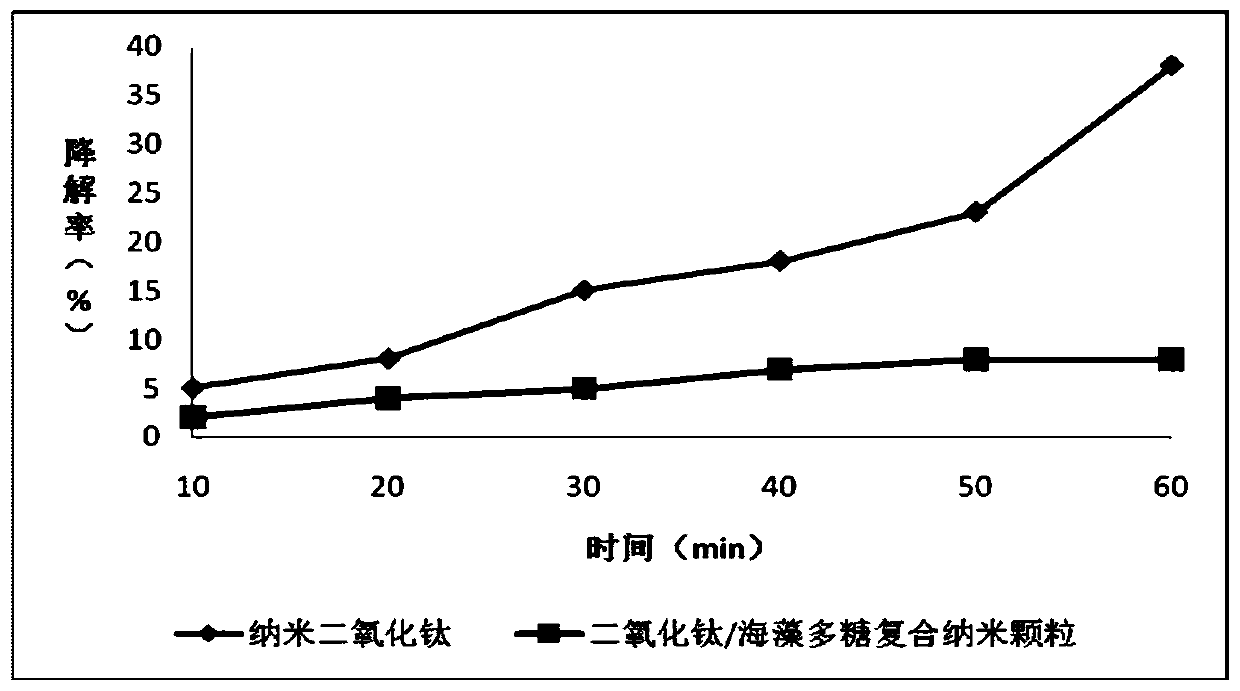

[0053] Effect application test example

[0054] Using the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com