Mesoporous silica protected ultra-thin ferro-nickel nitride composite material and preparation thereof

A technology of mesoporous silicon dioxide and ferronickel nitride, which is applied in the field of nanomaterials, can solve the problems of limiting the application of ferronickel nitride and increasing the size of ferronickel nitride nanoparticles, achieving mild conditions, improving catalytic performance, Simple and mild preparation method conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) The preparation method of nickel-iron hydrotalcite in this example adopts the method recorded in the document C.J.Wang, D.O'Hare,.Synthesis oflayered double hydroxide nanoparticles in a novelmicroemulsion.J.Mater.Chem.2012,22,21125. Proceed as follows:

[0030] 15 mL of n-butanol and 24 mL of N,N-dimethyltetradecyl tertiary amine were placed in the reactor, and stirred at high speed for 10 min to obtain a microemulsion environment. NiCl 2 ·6H 2 O and FeCl 3 ·6H 2 O was added to the reactor at a molar ratio of 3:1, the total amount of metal ions was 6 mmol, and mixed uniformly. The mixed solution was hydrothermally crystallized in a high-closed system at 120°C for 24h. After the reaction, the product was washed by centrifugation with ethanol-water (1:1) mixed solution for at least 5 times, and dried in an oven at 60°C to obtain nickel-iron hydrotalcite

[0031] 2) Nickel-iron hydrotalcite composite NiFe-LDH@SiO protected by mesoporous silica 2 Preparation of: ...

Embodiment 2~3

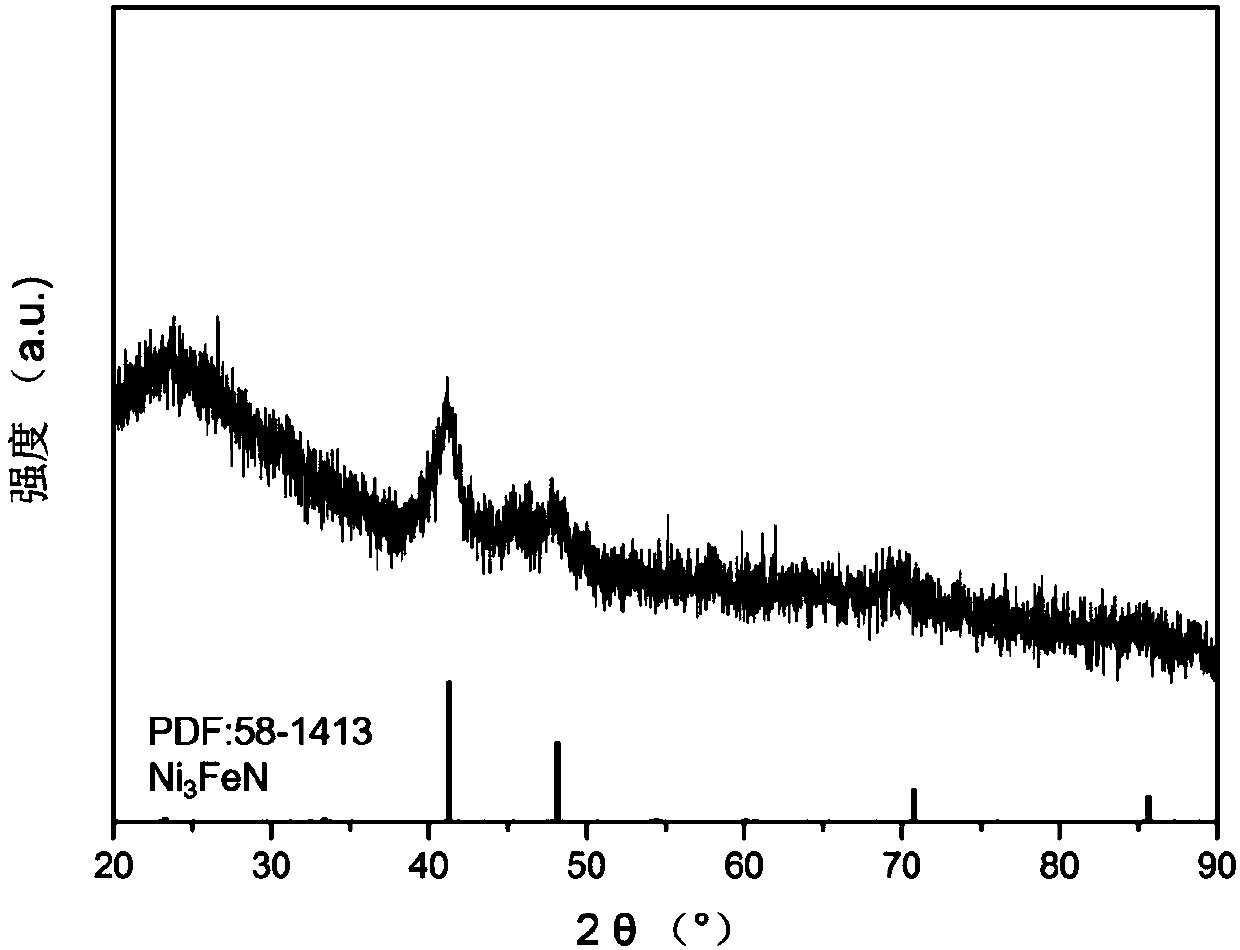

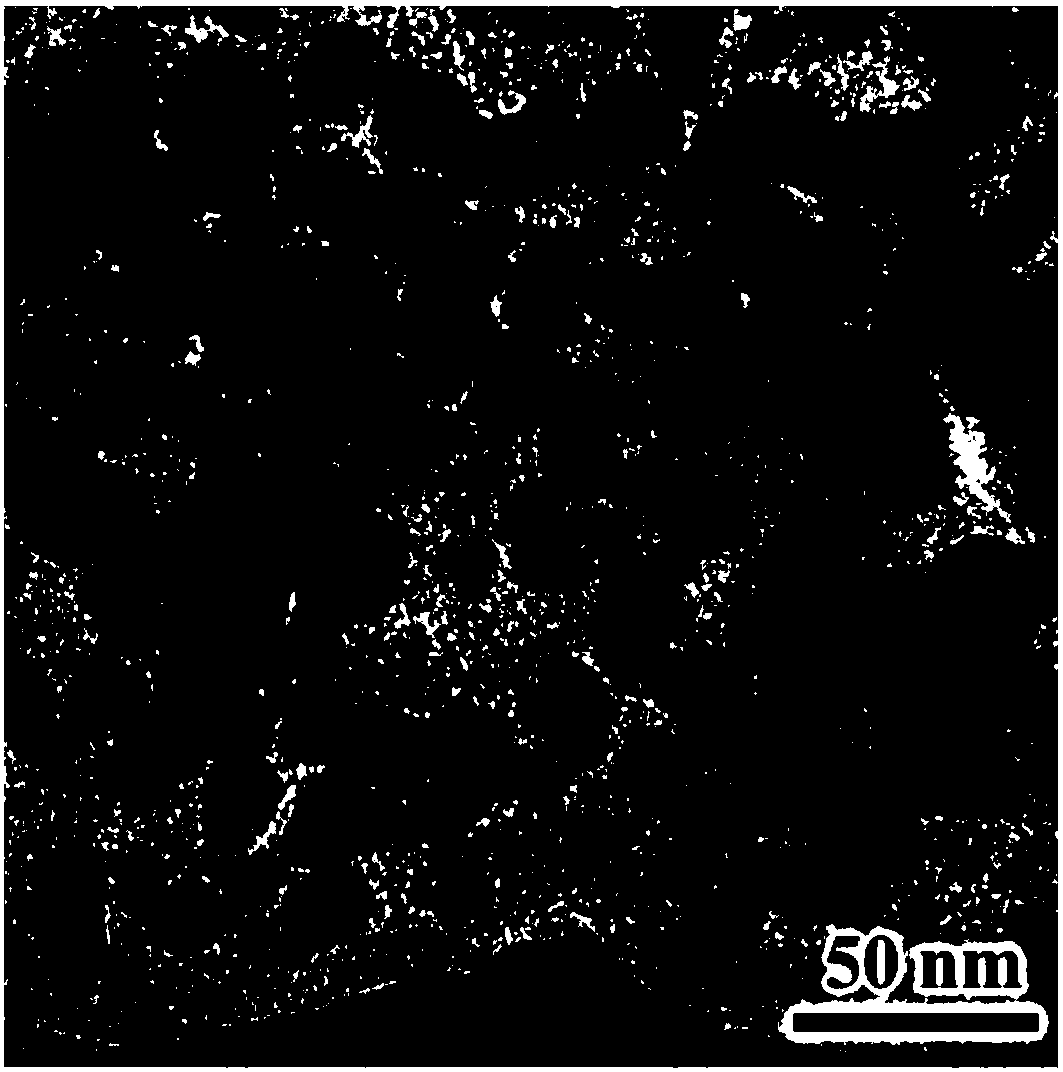

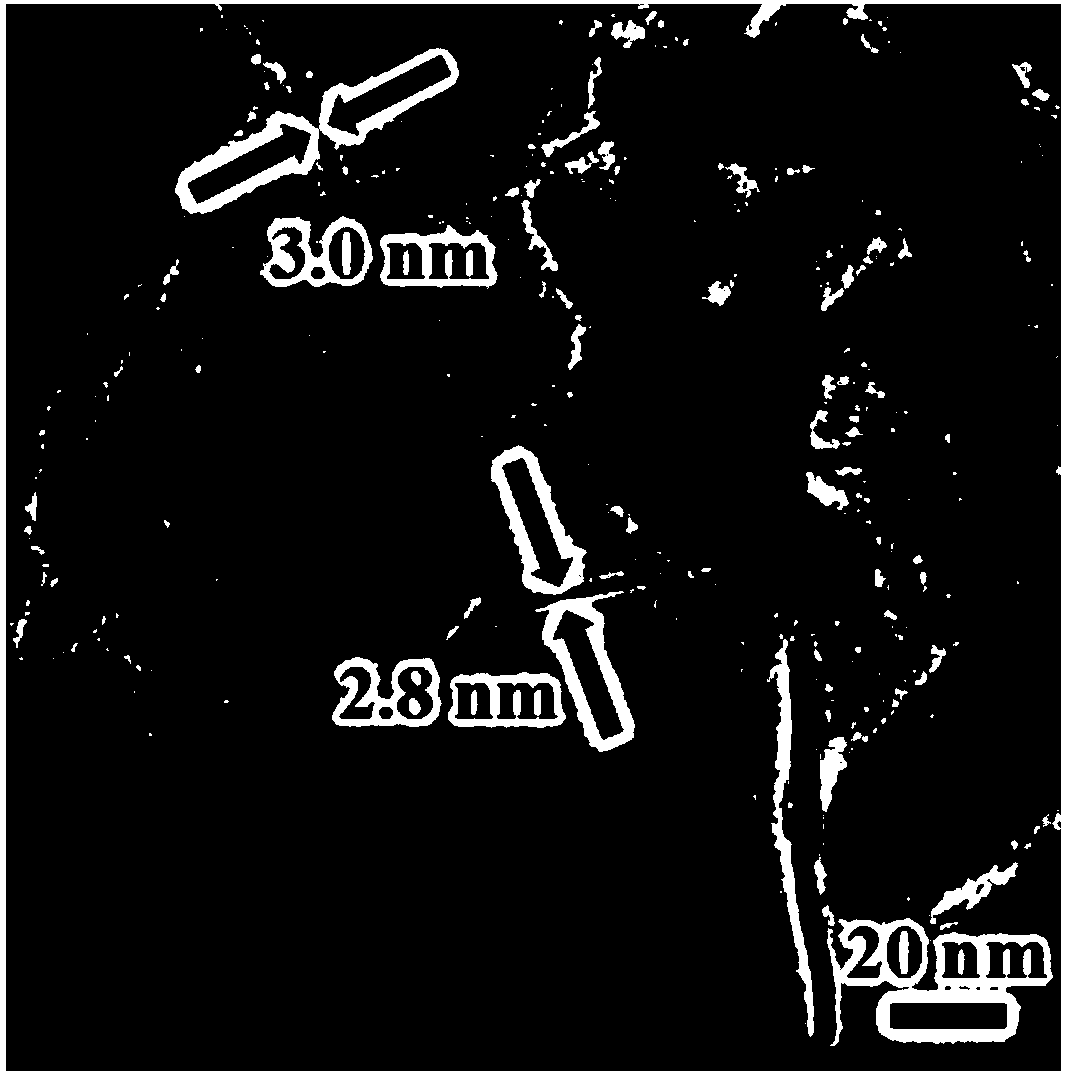

[0039] Repeat Example 1, the difference is only that the total amount of metal ions of the added nickel salt and iron salt is changed to 3mmol and 9mmol. The diameter of the ultra-thin nickel-iron nitride in the obtained composite catalyst is 18-22nm, the thickness is 2.8-3.2nm, SiO 2 The pore diameter of the mesopore is 2.4-3.2 nm.

Embodiment 4~9

[0041] Repeat Example 1, the only difference being that the nickel salt and the iron salt are changed in molar ratio: 2.2:1, 2.4:1, 2.6:1, 2.8:1, 3.2:1, 3.4:1. After changing the molar ratio of nickel salt and iron salt, the ultrathin nickel-iron nitride composite protected by mesoporous silica cannot be obtained. The result is an ultrathin nickel-iron nitride-nickel-iron alloy composite protected by mesoporous silica.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com