Reverse micelle system used for extracting proteins, and preparation method and application thereof

A technology of reverse micelles and proteins, applied in the field of bioengineering, to achieve good biodegradability, biocompatibility, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

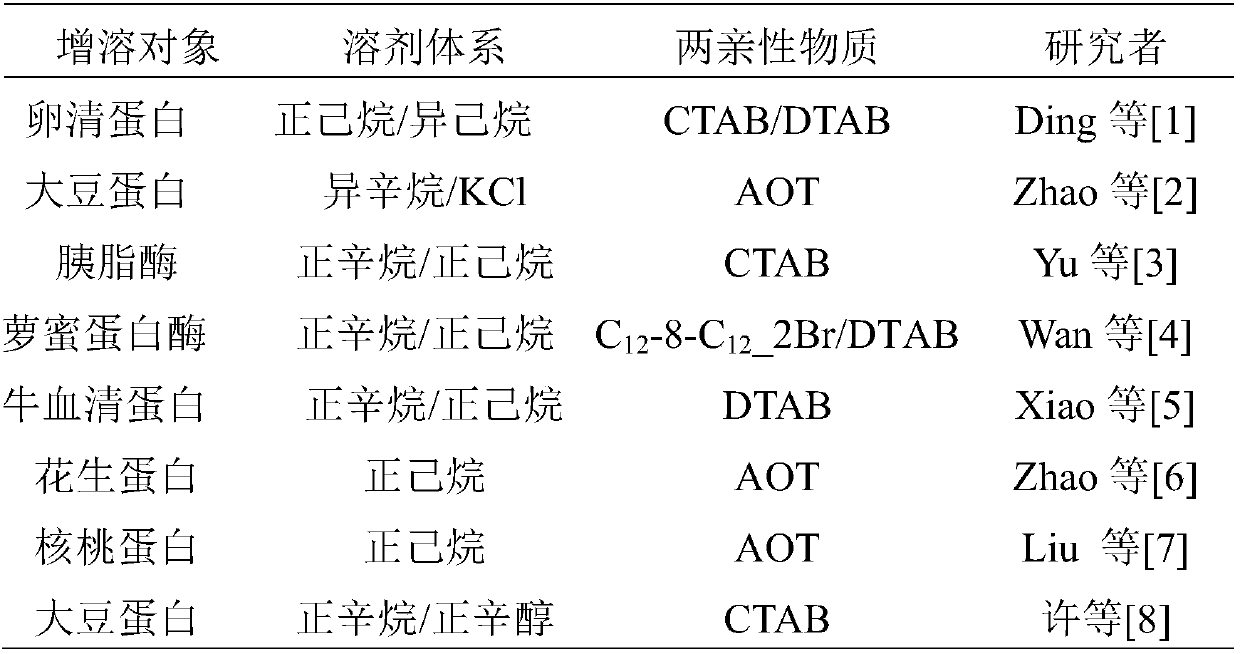

Method used

Image

Examples

Embodiment 1

[0033] The starch laurate reverse micelles system for extracting protein is prepared according to the following method:

[0034] 1. Synthesis of starch laurate ester

[0035] (1) Add 1 mol / L hydrochloric acid to cornstarch to keep the pH value of the solution at 3-5, stir and react at 60°C for 1-4h, filter, and wash the filter cake with distilled water until the pH is around 7 to obtain an average molecular weight of 20000-40000 degraded corn starch;

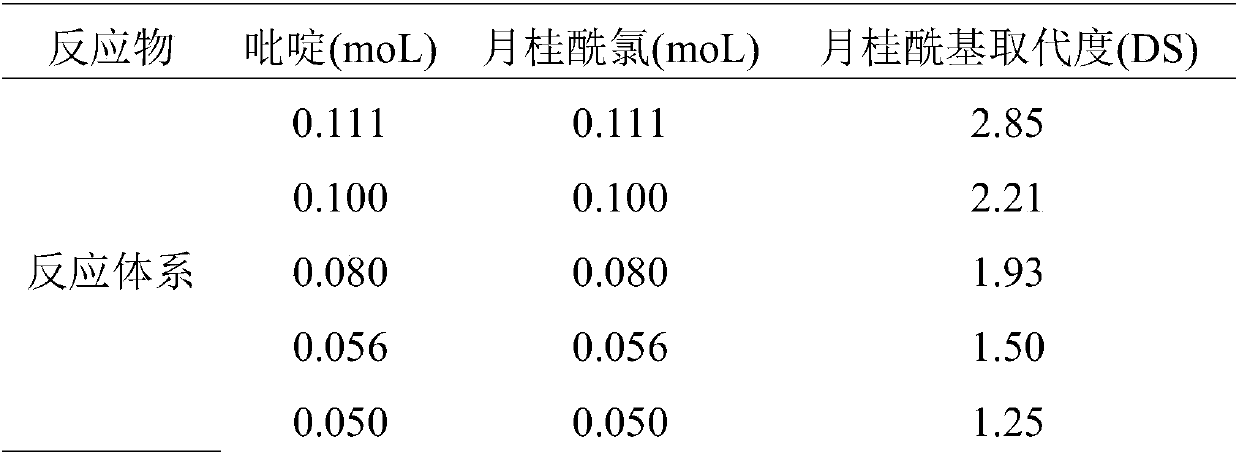

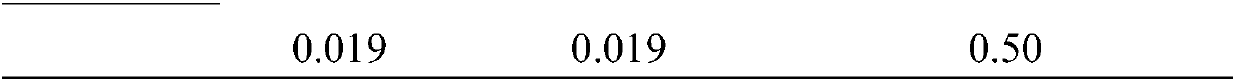

[0036] (2) Take 6g of degraded cornstarch in a three-necked flask, add 0.3g LiCl, fill the reaction system with nitrogen to replace the air in the system to achieve an anhydrous environment, add 50mL N-N dimethylacetamide, heat to 80°C, and fully Stir for 30 minutes, add pyridine (0.019-0.111moL) and lauroyl chloride (0.019-0.111moL) in different proportions to the reaction system, react for 30 minutes, cool to room temperature, add appropriate amount of ethanol, precipitate, suction filter, deionized water, anhydrous After wa...

Embodiment 2

[0046] Starch laurate reverse micellar system for extraction of soybean protein:

[0047] For the reverse micelle system (reverse micelle system 3) formed by the starch laurate ester with a lauroyl substitution degree of 1.93 prepared above, add distilled water to configure a reverse micelle system with a concentration of 1.0-4.0 mg / mL. Each system Add 0.015g of soybean protein powder to the mixture, shake at 35°C and 100r / min for 30min, then centrifuge at 8000r / min for 20min, the extraction system will be divided into two layers, the upper layer is the reverse micellar system for extracting protein, and the lower layer is the residue, The residue was removed by filtration, and the supernatant was taken to measure the absorbance A at 280 nm with a UV-Vis spectrophotometer. Using bovine serum albumin as a standard, make a standard curve, and its linear regression equation is: A=0.666C-0.0025, R 2 =0.9999; where A is the absorbance, and C is the protein concentration (mg / mL). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extraction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com